Company Introduce

UnitX, founded by a team of engineers from Stanford University, MIT and Google, is dedicated to accelerating human productivity in manufacturing through robotics and AI technology. As a robotics company, it solves the problem of surface defect detection through in-depth learning technology and robotic control technology, and provides one-stop automated detection solutions for global manufacturers by enabling industrial manufacturing with AI. At present, the system of individual technology has been adopted by the top 10 automotive suppliers and the top 2 new energy vehicle manufacturers in the world, serving more than 190 manufacturing enterprises in the world, helping manufacturing enterprises to improve product quality in an all-round way, effectively reduce quality costs, continuously release and maximize overall operational efficiency.

Exhibit brands

Exhibits

OpitX Intelligent Imaging System

-Software-defined optical system, with built-in 2 ³ ² lighting modes, fully adapted to different types of defect lighting requirements -High-speed imaging: the brightness is 100 times higher than that of traditional light source, supporting 50 lighting modes per second, and the flying speed of 1.0 M/S -Output 2D/2.5D high resolution defect imaging

CorteX Deep Learning & AI Inference System

Based on deep learning and image segmentation algorithm, defect features are identified and located in real time, and OK/NG judgment results are output in real time. -Zero foundation, easy to use Quickly create models through an intuitive UI interface -Fast training model The model can be trained with only 5 samples for each defect type -Adjustable threshold parameters Accurate detection of pixel-level defect and adjustment of threshold parameter can be realized -Scale across plant level It can realize the large-scale deployment of AI model in the global production line.

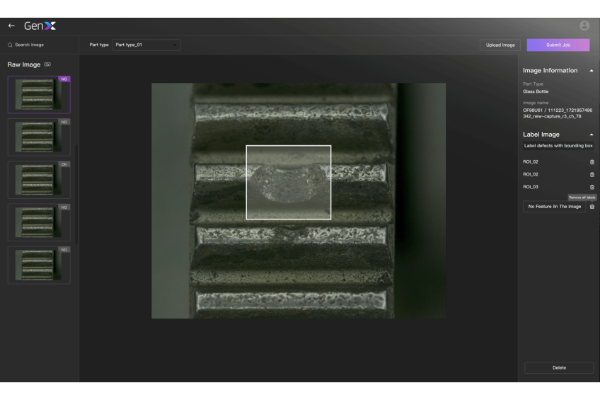

FleX-Gen

FleX-Gen is an image generation platform based on generative AI, which can simulate the generation of various rare and difficult-to-collect defect images to enrich the training data set, accelerate the iteration of model development, and continuously improve the accuracy and robustness of the detection model: -Defect generation: Only 3 defect samples are needed to create a high-precision AI model -Applied in all walks of life, it can achieve the effect of reducing the missed detection rate by 9 times. -Support for quick model change: in the high hybrid production mode, the model can be quickly changed to adapt to product model changes. -3x faster system deployment and full integration in less than a week -Save up to 30% on testing related costs in the first quarter -Deeply integrated with CorteX and deployable as a standalone product

Main products

FleX: High-precision inline visual inspection system, designed to cope with the most complex online visual inspection scenarios, with excellent detection accuracy and rapid deployment capabilities, seamlessly integrated into the online production environment, helping manufacturing enterprises to improve product quality in an all-round way, effectively reduce quality costs, maximize overall operational efficiency, real-time online production and full process visualization.