Company Introduce

A professional company dedicated to precision machining and manufacturing. Provide precision machinery manufacturing process plan, complete manufacturing work in its own factory, from product drawings to production process design, until the completion of manufacturing and service enterprises; Continuously innovate and improve mechanical manufacturing technology and process, provide customers with personalised technical services, produce products that meet their needs, and meet the final needs of customers. * Jingben Precision was established in 2005, with independent technical knowledge, production process, quality control and management system; * Dongguan Production Base was established in January 2012, with a registered capital of 20 million yuan and a plant area of 6000 square meters; * The company has a fixed, strong execution team, the number of employees is more than 100, more than 30% of employees have worked for more than 15 years; * The company has invested over RMB 100 million in production equipment, with more than 100 sets of precision processing equipment at home and abroad, equipped with high-precision testing instruments to ensure the accuracy and quality of mechanical processing; * Customers include a number of well-known international machinery manufacturers, and maintain long-term cooperative relations.

Exhibit brands

Exhibits

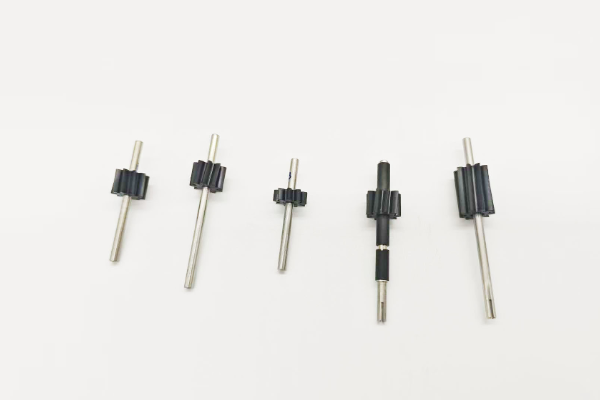

Medical grade stainless steel shaft PEEK gear

Precision injection PEEK gear, precision turning, gear accuracy 0.01 mm

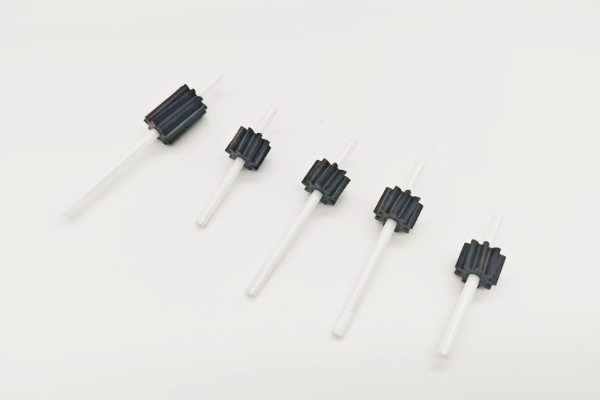

PEEK gear

High precision injection molded gears, precision ground gears, high performance materials

PEEK Ceramic Shaft Gear

High precision injection molded gears, precision turned gears, high performance materials

Ceramic valve sleeve

Ceramic sleeve, precision ground, dimensional accuracy +/-0.001 mm

Stainless steel shaft sleeve

Industrial pump core shaft sleeve, turning and milling composite processing, high precision grinding

High-precision combined shaft sleeve

Pump core shaft sleeve, turning and milling composite processing, high precision grinding, shaft sleeve precision fit

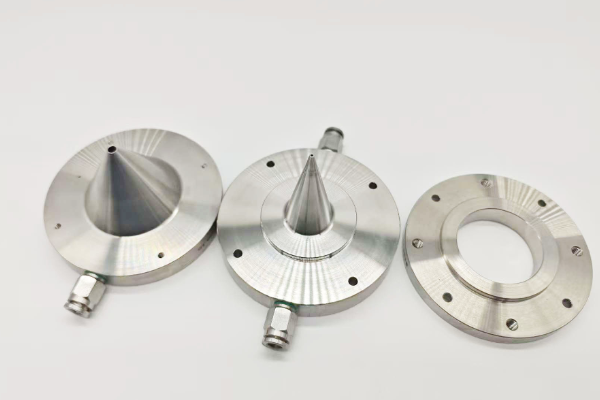

Aviation hydraulic valve sleeve

Aviation parts, high precision hydraulic valve housing, precision fit, roundness and cylindricity 0.0005mm

Precision turn-milling composite product

Citizen turning and milling composite lathe processing, once molding

Microporous dripper

Combination of precision turning, micro-hole processing and high-precision concentricity

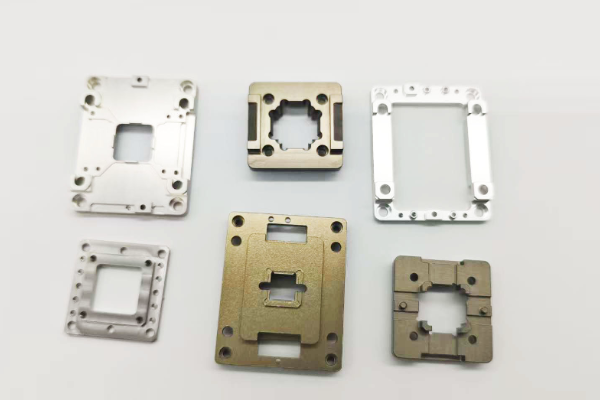

Semiconductor precision CNC machining

Semiconductor industry fixture, precision CNC machining, high-precision geometric tolerances

Pump body parts

Turn-milling composite processing, high-precision geometric tolerance, plane grinding, flatness up to 0.005 mm

Miniature pump body parts

Turn-milling combined processing, high precision hole position tolerance, grinding plane

Acrylic micro dripper

Turning and milling composite processing of acrylic material

Five-axis CNC precision part

High precision geometric tolerance, 5-axis CNC machining

Optical instrument housing

Precision CNC aluminum shell, anodized coating treatment

Main products

1. Plastic mold manufacturing • Professional assessment of mold structure • Mold design, fabrication, validation • Mold after-sales service 2. Precision parts processing • Primarily small and medium parts • Production of parts and components with complex machining processes • Machining accuracy of less than 1 µ 3. Plastic parts injection molding • Special barrel, plastic plasticizing temperature can reach more than 400 ° C • Customized screws for most engineering plastics with high fiber content • Professional mold maintenance to ensure timely delivery to customers 4. Product design and development • Product development and design according to customer requirements • Provide professional processing experience and verification during customer product development 5. Turnkey projects • Provide a package of solutions based on customer requirements • Complete equipment design, manufacture, assembly, validation and delivery 6. Product assembly • Dedicated product assembly line, work instructions, online testing • Partial or complete assembly of the product