Company Introduce

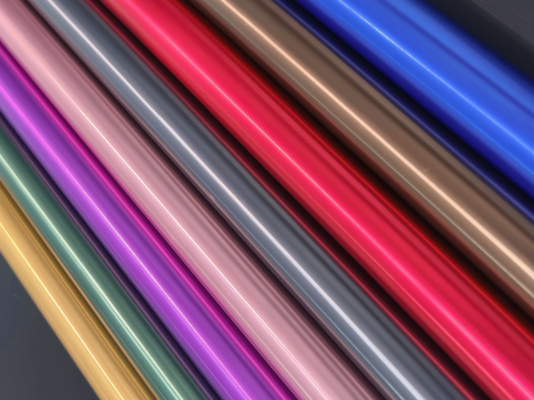

Guangdong Qide Group, founded in 2009, is dedicated to being the cornerstone of advanced manufacturing. The Group integrates investment, R&D, manufacturing, and solution provision, with its business deeply focused on cutting-edge fields such as aerospace, defense, humanoid robots, and the low-altitude economy. We also provide mature and reliable hardware industrial solutions for wearable devices, 3C electronics, and various precision components. Huizhou Qide Metal Material Co., Ltd., a core member of the Group, specializes in the R&D and manufacturing of high-performance aluminum alloys. We have built a complete industrial chain encompassing material research, melting & casting, extrusion, forging, and heat treatment, focusing on providing "high-strength, high-reliability" aluminum material solutions for the most demanding applications. Core Product Portfolio · Flagship Products: The 7075 series suitable for optical lenses, aerospace, defense, high-end sports equipment, and automotive/motorcycle parts. · Aluminum bars (T651 temper with tensile strength >640MPa; T7, T8, and O tempers available) · High-precision seamless aluminum tubes · Free-machining ground aluminum bars · Comprehensive System: Supported by robust manufacturing capabilities, we stably supply a full range of 2000 & 7000 series aluminum bars, tubes, and custom profiles. Typical Applications & Scenarios · Application Fields: Aircraft seats and luggage racks, humanoid robot joints, low-altitude vehicle structural components, UAVs, and more. · Processing Compatibility: Fully compatible with all mainstream and specialized processing techniques including CNC machining, lathe turning, Swiss-type automatic lathes (ground materials), forging, bending, and necking. Our Commitment & Assurance · Inventory Advantage: We maintain a stock of nearly one thousand tons of various specifications of 7075 aluminum bars, plates, and seamless tubes to ensure rapid response. · Service Model: We not only supply standard materials compliant with international standards but are also experts in providing end-to-end services—from material selection to custom production—tailored to your specific needs.

Exhibit brands

Exhibits

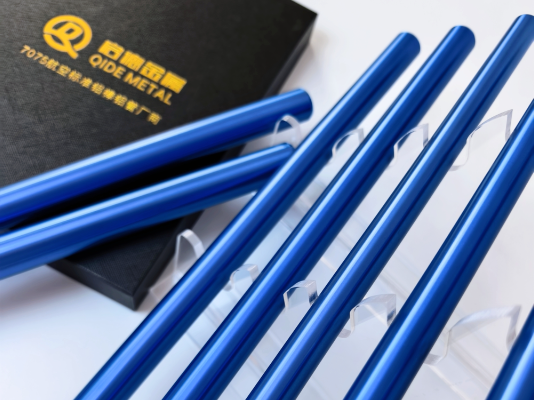

7075-O Temper Ground Aluminum Rod

Diameter Tolerance: ±0.01 mm Hardness: HRB ≤ 15 Tensile Strength: ≤ 228 MPa Yield Strength: ≤ 103 MPa Elongation: ≥ 16% Characteristics Low tensile and yield strength, high elongation, easy to deform and process, stable performance, excellent oxidation effect with batch-to-batch consistency, low internal stress after post-processing, and customizable special profiles. Applications Suitable as billet material for cold forging and warm forging of aerospace components and high-strength parts.

7075-O Temper Precision Drawn Aluminum Rod

Diameter Tolerance: ±0.05 mm Hardness: HRB ≤ 15 Tensile Strength: ≤ 228 MPa Yield Strength: ≤ 103 MPa Elongation: ≥ 16% Characteristics Low tensile and yield strength, high elongation, easy to deform and process, stable performance, excellent oxidation effect with consistent quality across batches, low internal stress after post-processing, and customizable special profiles. Applications Suitable as billet material for cold forging and warm forging of aerospace components and high-strength parts.

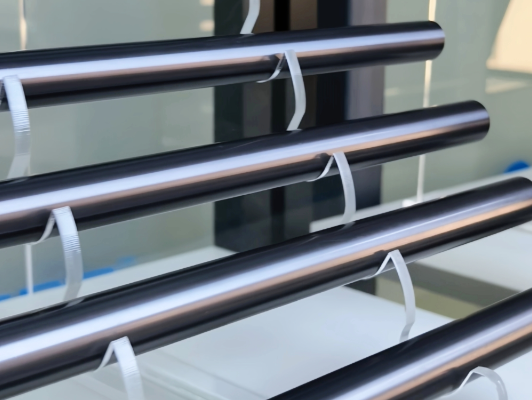

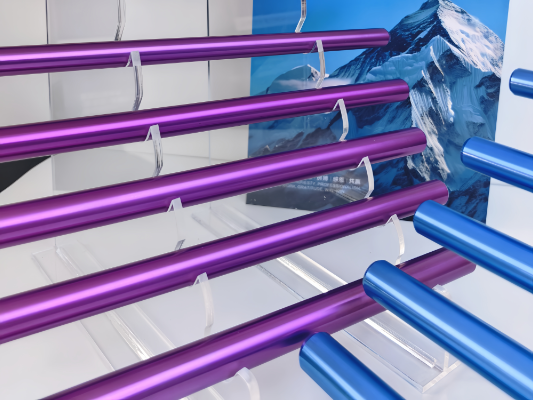

7075-T6 Temper Ground Seamless Aluminum Tube

Outer Diameter Tolerance: < 1 μm Inner Diameter Tolerance: ±0.05 mm (Smooth Inner Wall) Hardness: HRB 88 ± 2 Tensile Strength: > 590 MPa Yield Strength: > 570 MPa Elongation: ≥ 10% Characteristics Stable performance, excellent and consistent oxidation effect, easy to turn, and customizable special profiles are available. Applications Suitable for fields requiring high strength, lightweight, corrosion resistance and high-grade oxidation performance.

7075-T6 Temper Precision Drawn Seamless Aluminum Tube

Outer Diameter Tolerance: ±0.05 mm Inner Diameter Tolerance: ±0.05 mm (Smooth Inner Wall) Hardness: HRB 88 ± 2 Tensile Strength: > 590 MPa Yield Strength: > 570 MPa Elongation: ≥ 10% Characteristics Stable physical performance, excellent and consistent oxidation effect, easy to turn, and customizable special profiles. Applications Suitable for fields requiring high strength, lightweight, corrosion resistance and high-grade oxidation performance.

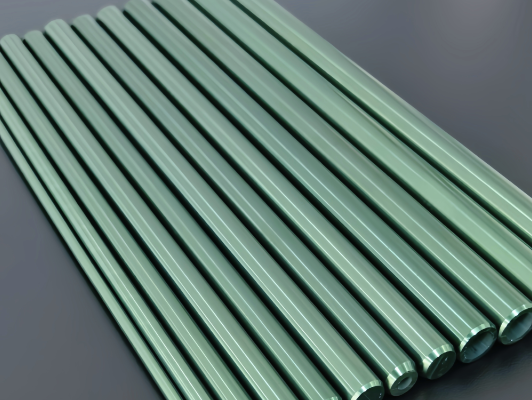

7075-T651 Temper Ground Aluminum Rod

Diameter Tolerance: < 1 μm Hardness: HRB 88 ± 2 Tensile Strength: > 590 MPa Yield Strength: > 570 MPa Elongation: ≥ 10% Characteristics Stable physical performance, excellent and batch-consistent oxidation effect, easy to turn, machining runout < 1 μm, and customizable special profiles. Applications Suitable for fields requiring high strength, lightweight, corrosion resistance and high-grade oxidation performance.

7075-T73 Temper Aluminum Rod

Hardness: HRB 80 ± 2 Tensile Strength: > 510 MPa Yield Strength: > 470 MPa Elongation: ≥ 12% ※ Symbol Corrected Characteristics Stable physical performance, excellent and batch-consistent oxidation effect, easy to turn, machining runout < 1 μm, and customizable special profiles. Applications Suitable for fields such as aerospace, which require high strength, lightweight, corrosion resistance (especially stress corrosion resistance) and high-demand hard anodizing.

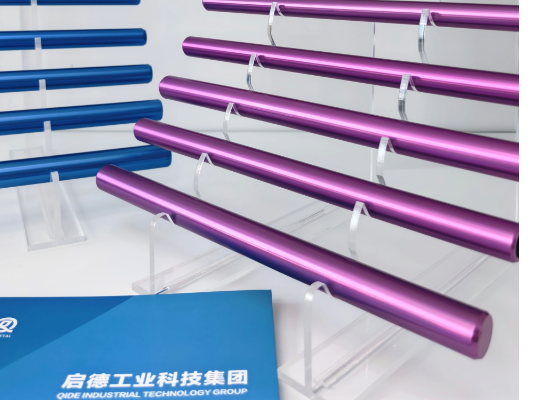

Main products

Specializing in the production of 7075 aviation aluminum alloy materials, standing 7075 seamless aluminum tubes, aluminum rods in stock. It can accept 7075, 70502A12 and other high-strength aviation aluminum and profile customization.