_01.png)

Company Introduce

Guangdong Yiyuan Yongzhuo Precision Technology Co., Ltd. (Hereinafter referred to as "Yiyuan Yongzhuo") takes root in Dongguan City, Guangdong Province, the "World Manufacturing Capital", covering an area of nearly 20000 square meters, and is a cutting-edge force in the field of precision CNC technology. The company integrates 20 years of core technology accumulation and cutting-edge innovative ideas. It focuses on providing high-precision and intelligent one-stop CNC machine tool solutions for the global high-end manufacturing industry, covering R & D and design, precision manufacturing, sales services, technical consultation and life-cycle maintenance. Yiyuan Yongzhuo inherits the technical team of multi-spindle CNC machine tools founded in 2005, and condenses the wisdom of two generations of craftsmen. By introducing international high-end technical talents and joining hands with senior technical teams, we have achieved leapfrog development in core areas.

Exhibit brands

Exhibits

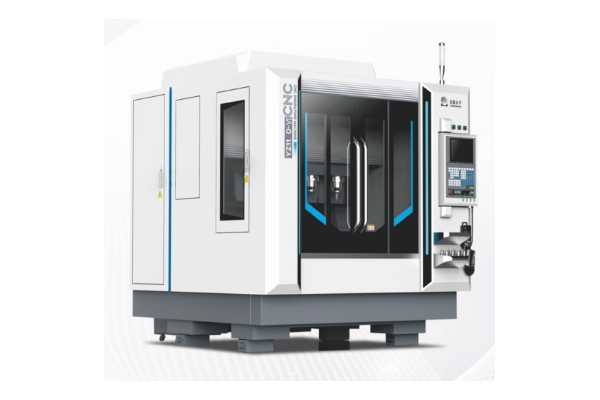

1. High-speed line-horse direct-drive machining center

1, automatic tool change system: servo drive disk tool magazine, advance tool preparation, significantly reduce tool change time, improve efficiency; With the tool magazine protection system, it can effectively solve the problem of scrap iron entering and prolong the service life of the tool magazine. 2, automatic chip removal system: internal two side chip rolling device, in the program with M code control, automatic control of start and stop, save manual cleaning time. 3. Natural (non-artificial) granite bed (1) High temperature resistance: its heat capacity is twice that of cast iron, its heat conduction is less than 1/20 of that of cast iron, and the reaction amplitude affected by temperature is only 1/3; (2) High damping: with good shock absorption and thermal stability, the damping ratio is more than 10 times that of cast iron, which can eliminate the combination of vibration absorption performance and linear motor caused by high acceleration, and greatly improve the surface quality of the workpiece and the service life of the machine tool; (3) Anti-interference 1) it is not affected by external magnetic force and has strong anti-interference ability; 2) Double X + double Y + double Z structure, which can realize independent compensation of each axis, and is suitable for batch processing of high-precision and complex hardware of special alloys such as aluminum alloy, carbon steel, stainless steel, etc. (4) High competitiveness: replace the traditional machining center, solve the problem of low efficiency of a single shafting station of a single machine tool, realize two shafting stations of a single machine tool, which is equivalent to improving the processing efficiency by 2 times, effectively solve the problem of high site, labor and equipment costs, and enhance the market competitiveness of products with B/C axis turntable and probe functional components. Can realize multi-angle proces of a workpiece in one-time clamping, realize independent compensation in X, Y and Z direction, realize extremely high dynamic performance and ensure that high precision requirement of the product. And that problem of difficult proces of the complex curved surface is sol.

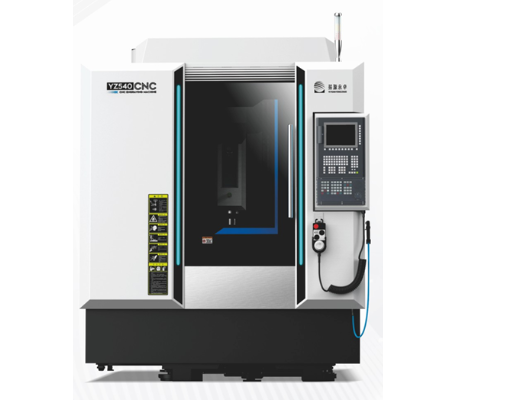

2. Single-head metal processing center

1, automatic tool change system: servo drive disk tool magazine, advance tool preparation, significantly reduce tool change time, improve efficiency; With the tool magazine protection system, it can effectively solve the problem of scrap iron entering and prolong the service life of the tool magazine. 2, automatic chip removal system: internal two side chip rolling device, in the program with M code control, automatic control of start and stop, save manual cleaning time 3. Natural (artificial) granite bed (1) High temperature resistance: its heat capacity is twice that of cast iron, its heat conduction is less than 1/20 of that of cast iron, and the reaction amplitude affected by temperature is only 1/3; (2) High damping: with good shock absorption and thermal stability, the damping ratio is more than 10 times that of cast iron, which can eliminate the combination of vibration absorption performance and linear motor caused by high acceleration, and greatly improve the surface quality of the workpiece and the service life of the machine tool; (3) Anti-interference 1) it is not affected by external magnetic force and has strong anti-interference ability; 2) Adopt imported/domestic famous brand precision grinding screw rod and guide rail, servo motor, control system and other core accessories; 4) High competitiveness: instead of the traditional machining center, the natural marble bed and beam are adopted. The gantry structure design makes the main shaft of the equipment have smaller overhang, which is more suitable for high-speed cutting and has more advantages in accuracy, stability, deformation resistance and surface roughness quality; 5) High precision: equipped with B/C axis turntable, it can realize multi-angle processing of workpieces in one clamping, realize extremely high dynamic performance, and solve the problem of difficult processing of complex curved surfaces. 6) High applicability: applicable to cold carving processing of mobile phone glass cover, mold, relief, smart wear, sapphire, ceramics, zirconia, aluminum alloy, stainless steel, titanium alloy.

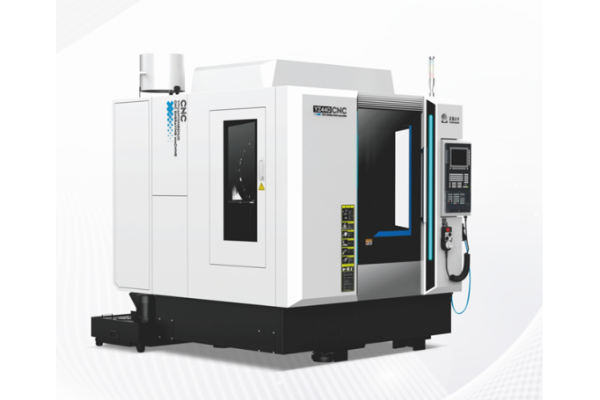

Two-channel metal machining center

1, automatic tool change system: servo drive disk tool magazine, advance tool preparation, significantly reduce tool change time, improve efficiency; With the tool magazine protection system, it can effectively solve the problem of scrap iron entering and prolong the service life of the tool magazine. 2, automatic chip removal system: internal two side chip rolling device, in the program with M code control, automatic control of start and stop, save manual cleaning time. 3. Natural (non-artificial) granite bed (1) High temperature resistance: its heat capacity is twice that of cast iron, its heat conduction is less than 1/20 of that of cast iron, and the reaction amplitude affected by temperature is only 1/3; (2) High damping: with good shock absorption and thermal stability, the damping ratio is more than 10 times that of cast iron, which can eliminate the combination of vibration absorption performance and linear motor caused by high acceleration, and greatly improve the surface quality of the workpiece and the service life of the machine tool; (3) Anti-interference 1) it is not affected by external magnetic force and has strong anti-interference ability; 2) Double X + double Y + double Z structure, which can realize independent compensation of each axis, and is suitable for batch processing of high-precision and complex hardware of special alloys such as aluminum alloy, carbon steel, stainless steel, etc. (4) High competitiveness: replace the traditional machining center, solve the problem of low efficiency of a single shafting station of a single machine tool, realize two shafting stations of a single machine tool, which is equivalent to improving the processing efficiency by 2 times, effectively solve the problem of high site, labor and equipment costs, and enhance the market competitiveness of products with B/C axis turntable and probe functional components. Can realize multi-angle proces of a workpiece in one-time clamping, realize independent compensation in X, Y and Z direction, realize extremely high dynamic performance and ensure that high precision requirement of the product. And that problem of difficult proces of the complex curved surface is sol.

Four-head metal processing center

1. Automatic tool change system: in-line/matrix 21 T tool magazine, prepare tools in advance, greatly reduce tool change time and improve efficiency; With the tool magazine protection system, it can effectively solve the problem of scrap iron entering and prolong the service life of the tool magazine. 2, automatic chip removal system: internal two side chip rolling device, in the program with M code control, automatic control of start and stop, save manual cleaning time. 3. Natural (non-artificial) granite bed (1) High temperature resistance: its heat capacity is twice that of cast iron, its heat conduction is less than 1/20 of that of cast iron, and the reaction amplitude affected by temperature is only 1/3. (2) High damping: with good shock absorption and thermal stability, the damping ratio is more than 10 times that of cast iron, which can eliminate the combination of vibration absorption performance and linear motor caused by high acceleration, and greatly improve the surface quality of the workpiece and the service life of the machine tool. (3) Anti-interference 1) it is not affected by external magnetic force and has strong anti-interference ability; 2) Four Z-axis + four B-axis DD motor configuration, which can realize the batch processing of 3D high-precision and complex structure hardware such as mobile phones, smart wear, headphones, etc. And (4) high competitiveness: that traditional machine center is replace, the problem of low efficiency of a single shafting station of a single machine tool is solved, four shafting station of a single machine tool are realized, the processing efficiency is improved by four times, the problems of high site, labor and equipment costs are effectively solved, and the market competitiveness of products is improved. And (5) high efficiency: that displacement of the four B axe in the X direction can be controlled by the system servo, so as to solve the problem of long time consumption in the proces of customer operation, machine adjustment and model change. (6) High precision: DD motor transmission, can realize multi-angle processing of the workpiece in one clamping, can achieve extremely high dynamic performance, and solve the problem of difficult processing of complex curved surface.

Six-head Metalworking Center

1. The P-level precision guide rail is designed with half-pitch installation, and the connection strength is doubled; 2. Grade C3 precision ball screw 3, ultra-precision high-speed electric spindle: integrated structure and built-in sensor, can monitor its processing information at any time, to ensure stable processing efficiency 4. Automatic tool change system: in-line/matrix 21 T tool magazine, prepare tools in advance, greatly reduce tool change time and improve efficiency; With the tool magazine protection system, it can effectively solve the problem of scrap iron entering and prolong the service life of the tool magazine. 5, automatic chip removal system: internal two side chip rolling device, in the program with M code control, automatic control of start and stop, save manual cleaning time 6. Natural (non-artificial) granite bed (1) High temperature resistance: its heat capacity is twice that of cast iron, its heat conduction is less than 1/20 of that of cast iron, and the reaction amplitude affected by temperature is only 1/3. (2) High damping: with good shock absorption and thermal stability, the damping ratio is more than 10 times that of cast iron, which can eliminate the combination of vibration absorption performance and linear motor caused by high acceleration, and greatly improve the surface quality of the workpiece and the service life of the machine tool. (3) Anti-interference: It is not affected by external magnetic force and has strong anti-interference ability. 6 Z-axis linkage configuration, multiple pieces of products can be processed simultaneously High competitiveness: instead of the traditional machining center, one machine tool only uses one shafting station, and now one machine tool can use six shafting stations, which is equivalent to improving the processing efficiency by 6 times, ensuring the processing efficiency of customers, effectively solving the problem of high site, labor and equipment costs, and enhancing the market competitiveness.

Main products

Our company focuses on the design and manufacture of CNC machine tools for small precision industry, and has the ability of "full stack self-research" and "vertical integration" of the whole industry chain. The main products are: 1. High-speed line-horse direct-drive machining center 2. Single-head metal processing center 3. Dual-channel metal processing center 4. Four-head metal processing center 5. Six-head metal processing center