-1595489653181.png)

Company Introduce

Hankai Technology Co., Ltd. Shenzhen is a high-tech company focusing on machine vision, independently developing and manufacturing of automated visual inspection equipment, deep learning visual inspection equipment, smart cameras, online visual inspection and visual inspection software. Among the core technical personnel of Hankai R&D team, there are many industry-leading personnel with more than ten years of machine vision R&D experience. Strong R&D strength of Hankai has obtained a number of patents in the field of machine vision inspection, and its R&D capabilities have reached the advanced level of the industry. Hankai aims to help customers solve production quality problems, help customers optimize production processes, reduce production costs, improve production efficiency, and ensure that products have perfect quality. Hankai has provided industry-leading visual inspection products and solutions to many leading companies in the industry, served more than 100 industries now.

Exhibit brands

Exhibits

Deep learning visual inspection equipment

Hankai Vision inspection Equipment, in combination with Hankai's Deep Learning Vision System, is designed for fully automated inspection of surface defects, dimensions, color differences, and character recognition of components across various industries. Hankai aims to help customers, address production quality issues, optimize manufacturing processes, reduce production costs,improve production efficiency, and ensure that products meet the highest quality standards. Hankai'sautomated vision inspection equipment and online vision inspection products are widely used in fieldssuch as mobile phones, electronics, precision hardware, plastic injection molding. industrial manufacturing, automotive manufacturing, mechanical processing, powder metallurgy, new energy.components, solar energy, electrical appliances, apparel, daily necessities, food, medical, pharmaceutical, military, aerospace, and more.

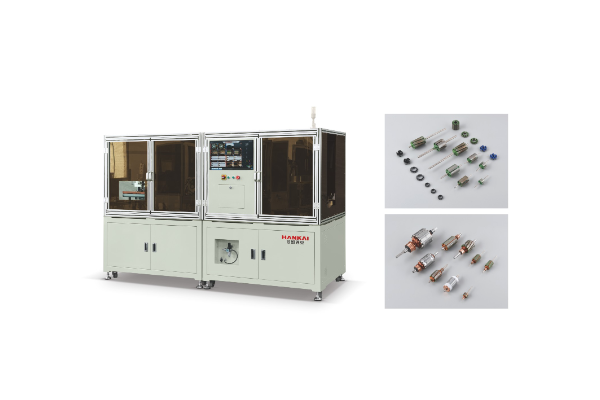

Rotor AI Visual Inspection System

Fully automated inspection of rotor appearance defects and dimensions, with all inspection items completed in a single inspection cycle. Highly versatile, a single device can inspect multiple types of rotor products. Industry-leading 360-degree defect inspection of rotor inner and outer walls, with an inspection speed of 8-15 units per minute and an accuracy of up to 0.001mm.

Iron Core AI Visual Inspection System

Fully automatic inspection of iron core appearance defects and dimensions, with all inspection items completed in a single pass. Highly versatile, a single device can inspect multiple types of iron core products. Industry-leading 360-degree defect inspection of the inner and outer walls of iron cores with inspection speeds of 30-45 units per minute and accuracy up to 0.001mm

Commutator Visual Inspection System

Fully automated inspection of commutator appearance defects and dimensions, with all inspection items completed in a single cycle.. It has high versatility, and a single device can inspect multiple types of commutator products. Industry-leading 360-degree inspection of internal and external commutator surfaces, achieving speeds of up to 800 units per minute with an accuracy of 0.001 mm.

Main products

Hankai Technology Co., Ltd. Shenzhen is a high-tech company focusing on machine vision, independently developing and manufacturing of automated visual inspection equipment, deep learning visual inspection equipment, smart cameras, online visual inspection and visual inspection software. Hankai automated visual inspection equipment and online visual inspection products are widely used in mobile phones, electronic products, micromotor products, electroacoustic products, precision hardware, injection products, automobile manufacturing, powder metallurgy, new energy, components, electrical appliances, daily necessities, medical care, military industry, aerospace and other fields.