Company Introduce

Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. was founded in 2004 and headquartered in Shanghai. As a high-tech enterprise, Kaiwei specialized in R & D and production of industrial sealing system and robot foaming equipment. The company has professional R & D institutions, perfect technical innovation system, and provides automation electrical solutions for well-known enterprises at home and abroad. Kaiwei adheres to the enterprise tenet of "technology as the guide, talent as the foundation, quality as the life, reputation as the foundation". It has more than 30 technical R & D personnel, and the overall R & D level ranks the forefront of the same industry in China. The company has obtained 30 national patents leading in technological innovation, such as robot quantitative foaming machine. Automatic foam sealing machine are widely used in electric power, metallurgy, coal, petroleum, chemical industry, pharmaceutical, military industry, transportation, port, municipal construction, automation, automobile, electrical cabinet, air filter, air conditioning purification equipment, packaging, electronic components, lamps, new energy and other fields. Kaiwei products have passed ATEX, CCC, CE, INGRESS PROTECTION, factory explosion-proof certification and ISO9001-2000 international quality system certification. Product quality has been unanimously recognized and highly praised by customers. Automatic foam sealing machines sell well in China, and are exported to more than 20 countries and regions, such as Germany, America, Italy, Vietnam, Chile, Russia, India, Middle East, Southeast Asia, South America, etc.

Exhibit brands

Exhibits

Auto Foam Sealing Machine KW-520

Widely used in various sealed products such as automobiles, new energy, high and low-voltage distribution cabinets, refrigeration, purification and filtration, waterproof boxes, explosion-proof industries, lighting fixtures, etc. Equipped with an intelligent control system that can be customized in Chinese, English, and other languages. Workpiece dimensions, drawings, and technical parameters can be stored in the system; Using a six-axis motion control card, Kaiwei's independently developed adhesive control system; The system has a glue path simulation function: the mixing head completes the glue path according to the drawing without dispensing glue; The system control adopts three-axis linkage; The graphic import function eliminates the need to edit code programs and reduces the requirements for operators.

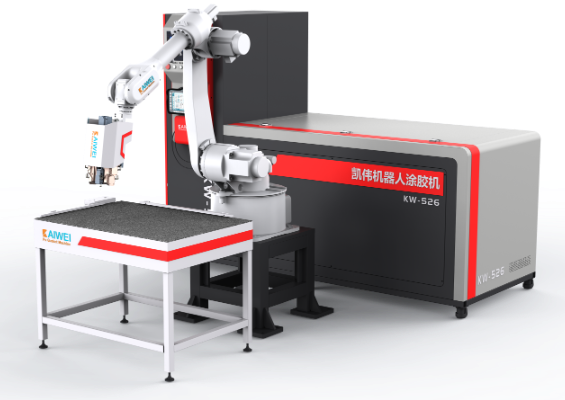

Auto Foam Sealing Machine KW-526

Suitable for foam sealing, bonding, and pouring of flat or nonflat workpieces, the viscosity range of the adhesive can range from several hundred to several million centipoises. Small footprint, high level of intelligence, and simple maintenance. The system's intelligent operation simulation function completely eliminates machining errors caused by human-size issues during the production process. Intelligent graphic automatic generation function, two-dimensional products do not require programming. Glue can be applied to any shape or trajectory (circular, square, trapezoidal, L-shaped, C-shaped, straight, etc.), and the thickness of any segment of the adhesive strip in a single shape can be changed. The system has a simulated memory function, which can achieve calibration without graphics.

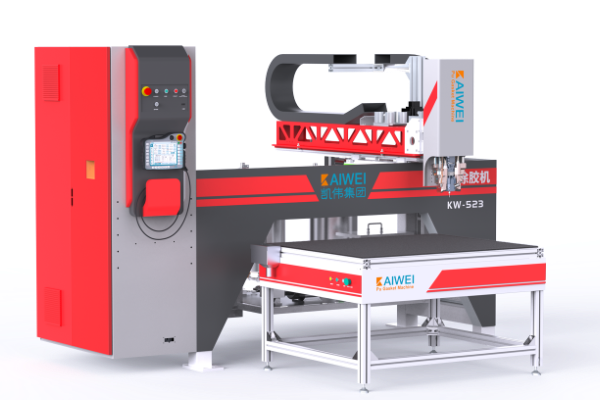

Auto Foam Sealing Machine KW-523

The technology of on-site sealing, dispensing and pouring molding is adopted, and the processed sealing strip can be as thin as 2mm, especially suitable for sealing small workpieces. This equipment not only processes more accurately but also is easy to operate. The processed sealing strip is formed in one go, without seams, and has strong adhesion. Humanized intelligent control system: both two-dimensional and three-dimensional workpieces can be switched for processing; Fault alarm function; Automatic graphic generation system; Low pressure alarm function; Intelligent water cleaning function; Digital display of AB material pressure, convenient ingredient adjustment; Raw material barrel: automatic temperature control double-layer stainless steel material barrel, automatic alarm when there is no material, automatic mixing device, and automatic air replenishment.

Auto Foam Sealing Machine KW-510

Suitable for explosion-proof cabinets, cabinet cases, imitation Weitu and other products, with 360 degree seamless connection, simple operation, time-saving and labor-saving, efficient and stable, waterproof and dustproof IP65. Equipped with an intelligent control system that can be customized in Chinese, English, and other languages. Workpiece dimensions, drawings, and technical parameters can be stored in the system; Using a six-axis motion control card, Kaiwei's independently developed adhesive control system; The system has a glue path simulation function: the mixing head completes the glue path according to the drawing without dispensing glue; The system control adopts three-axis linkage; The graphic import function eliminates the need to edit code programs and reduces the requirements for operators.

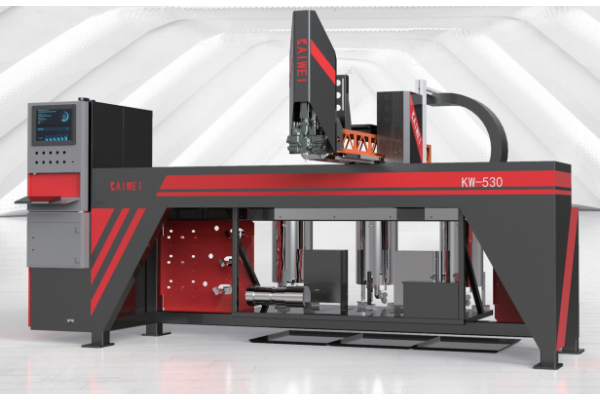

Air Compressor Dedicated Adhesive Dispenser KW-530

Widely used in various sealed products such as automobiles, new energy, high and low voltage distribution cabinets, refrigeration, purification and filtration, waterproof boxes, explosion-proof industries, lighting fixtures, etc., Using an integrated industrial touch screen, it can rotate 0-90 degrees, making it easy to operate, transport, and debug. Equipped with a manual operator as standard, the raw material tank adopts an integrated design, and all internal motors and components use imported brands. This device is equipped with a three component feeding device, equipped with a three component mixing head, to meet the needs of customers for different products corresponding to different raw materials, thereby avoiding the trouble of replacing raw materials. Equipment dispensing width: 5-30mm (4mm inside the slot).

KW-520M Fully Automatic In-Vehicle Adhesive Dispensing Equipment

Suitable for sealing new energy solar panels and new energy vehicle battery trays, waterproof and dustproof, with a seamless 360 ° connection. Adopting an integrated industrial touch screen that can rotate 0-90 °, easy to operate, equipped with a wireless keyboard and mouse. Equipped with a manual operator as standard, it can operate the equipment more conveniently and quickly. The combination of the body and the car allows for mobile operation and easy transportation. The structure and appearance design can be customized according to customer requirements.

Main products

Auto foam sealing machine, sealing foam glue double, normal micro automatic dispensing machine, sealing strip foaming dispensing machine, polyurethane AB two-component dispensing equipment, industrial sealing solutions, explosion-proof electrical equipment, industrial flat inkjet printer equipment, automatic bolt equipment and spare parts