-透明.png)

Company Introduce

MT is a high-tech enterprise integrating R&D of high-precision magnesium alloy thixomolding technology, equipment manufacturing and product processing. Its core team has been deeply engaged in this field since 2008, mastering domestically leading core technology of thixomolding injection molding, breaking foreign monopolies, significantly reducing the purchase and maintenance costs of magnesium alloy thixomolding equipment and the manufacturing costs of magnesium alloy products, and breaking the bottleneck of the wide application of magnesium alloys. The 300T, 650T, 800T and 1500T thixomolding equipment developed by EMT have been put into production; the 2500T and 4000T equipment have completed the design and will be used to produce large components for passenger cars in the future. The equipment features safety (no exposure of high-temperature molten metal), environmental protection (no harmful SF₆ gas), energy saving (60% reduction in energy consumption), high precision (0.01mm) and high efficiency (1-4 pieces per minute), with a maintenance cycle of nearly 200,000 mold cycles and strong reliability. EMT has the full-process processing capability for magnesium alloy products, covering the entire process of "thixomolding forming - CNC machining - passivation - spraying - laser engraving - inspection, packaging and delivery". The batch qualification rate of finished products reaches 99%, and customer satisfaction exceeds 95 points. Its products cover fields such as 3C, new energy vehicles, outdoor products and medical equipment, and have served well-known domestic and foreign customers. Relying on the advantages of rapid technological iteration, strict cost control and strong backup expert team, EMT continues to deepen its presence in the magnesium alloy industry, and is determined to become a supporter of the "China Metal" magnesium alloy industrial chain and an innovative leader in the field of high-precision magnesium alloy forming.

Exhibit brands

Exhibits

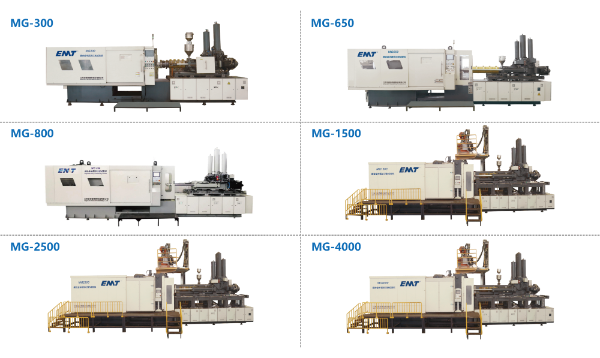

Series of Magnesium Alloy Thixomolding Injection Molding Equipment

The core team of EMT is the first batch of domestic developers of thixomolding technology, which has been working hard for more than ten years to break the monopoly of foreign countries and launched 300T-4000T series machines. The equipment is safe, environmentally friendly, precise and efficient, its mechanical properties are 20% higher than those of die-casting, its energy consumption is 60% lower.

(1).png)

Full-Process OEM Processing of Magnesium Alloy Products

Relying on the complete chain of "thixomolding forming-precision processing-fine grinding-professional film-customized spraying", we can achieve one-stop delivery of raw materials to finished products, shorten the cycle and reduce costs. It can undertake the processing needs of magnesium alloy products such as 3C products, medical equipment, outdoor products, auto parts and electric bicycles, with strict process control.

Main products

1.Magnesium alloy thixomolding equipment The core team of EMT is the first batch of domestic developers of thixomolding technology, which has been working hard for more than ten years to break the monopoly of foreign countries and launched 300T-4000T series machines. The equipment is safe, environmentally friendly, precise and efficient, its mechanical properties are 20% higher than those of die-casting, its energy consumption is 60% lower. 2.Full-process processing of magnesium alloy products Relying on the complete chain of "thixomolding forming-precision processing-fine grinding-professional film-customized spraying", we can achieve one-stop delivery of raw materials to finished products, shorten the cycle and reduce costs. It can undertake the processing needs of magnesium alloy products such as 3C products, medical equipment, outdoor products, auto parts and electric bicycles, with strict process control.