.png)

Company Introduce

Jinqi Intelligent Equipment (Guangdong) Co., Ltd. is the world's leading intelligent equipment manufacturer and innovative solution provider, dedicated to creating excellent quality intelligent equipment for global manufacturing customers. We focus on core areas such as laser cutting equipment, precision machining centers, woodworking equipment automation, laser welding automation and intelligent production lines, relying on cutting-edge technology and exquisite craftsmanship to ensure that each equipment has excellent performance, reliability and durability. We are well aware of industry differences and provide tailor-made intelligent production tools to maximize customer productivity. Quality begins with products and ends with service. We always take customer needs as the starting point, and build an efficient service network and professional team covering the whole world. From solution consultation, equipment delivery to continuous technical support and maintenance, Jinqi provides high-quality and customized services throughout the product life cycle to ensure customers'worry-free operation and continuous improvement of value. Jinqi Technology is not only a provider of intelligent equipment, but also a reliable partner for you to pursue excellent production efficiency and long-term success. With excellent product quality and perfect service experience, we enable the transformation, upgrading and sustainable development of global manufacturing industry.

Exhibit brands

Exhibits

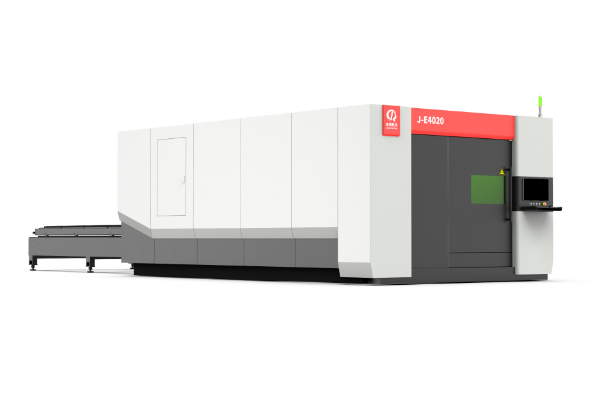

3216 High Speed Laser Cutting Machine

Fiber laser cutting machine, exchange platform large surround, super high acceleration, greatly improve the cutting efficiency

Flame laser compound cutting machine

The ground-rail flame laser compound cutting machine can realize ultra-thick plate cutting. Compared with pure laser cutting, it has thicker thickness and smaller taper. Compared with pure flame cutting, it has faster speed and thicker perforation thickness. It can be called the terminator of thick plate cutting.

Main products

Metal laser cutting machine (including but not limited to: plate cutting machine, pipe cutting machine, 3D cutting machine, uncoiling, leveling and cutting production line, etc.); automatic equipment (including but not limited to: automatic flexible sheet metal production line, automatic welding production line, flange production line, kitchenware production line, electric cabinet production line, automatic machine processing production line, etc.); Woodworking machinery and equipment (including but not limited to: engraving machine, drilling and cutting machine, in-line tool change processing center, door and wall cabinet processing center, woodworking automation production line), aluminum profile intelligent processing center, semiconductor and chip cutting machine, etc.