Company Introduce

Zhejiang Jiafeng Power Technology Co., Ltd. is a motor manufacturer founded in 2020 and located in Jiashan County, Zhejiang Province. Mainly according to the needs of users, customized research and development and production of various types of motors. At present, the products mainly include AC asynchronous induction water-cooled motors, AC synchronous permanent magnet water-cooled motors, AC synchronous non-magnetic motors, DC brushless motors, servo motors, etc. The products are suitable for screw vacuum pumps, screw compressors, compressors, water pumps and other high-end equipment. With advanced production technology, rigorous management process and perfect quality assurance system, the company has successfully built a comprehensive and traceable digital management platform for Jiafeng Motor to ensure that every motor, every key component and every key production process has a traceable code and a traceable number. The company has always adhered to the guiding ideology of "surviving by quality and developing by innovation". Quality and innovation as the cornerstone of enterprise development, the pursuit of professional and single-minded; "green drive, endless" as the development concept, and constantly meet the needs of customers for green sustainable development.

Exhibit brands

Exhibits

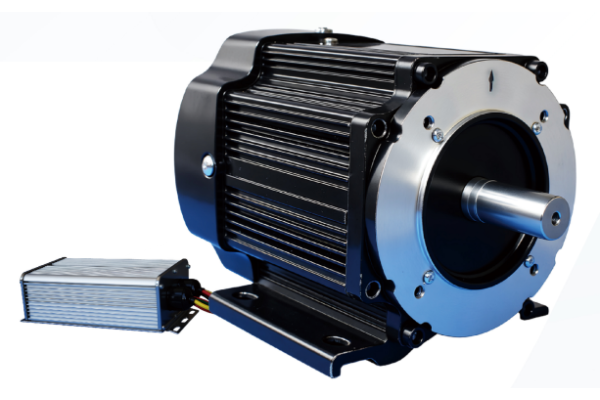

Fully seal water-cooled motor

Fully sealed water permanent magnet synchronous motor represents a significant advance in modern motor technology, which perfectly combines the high efficiency characteristics of permanent magnet synchronous motor with the hermetically sealed waterproof design. Excellent heat dissipation performance and power density are the most prominent advantages of fully sealed water-cooled permanent magnet synchronous motor. The cooling efficiency of the liquid cooling system is far higher than that of the air cooling mode, so that the motor can output more power in a smaller volume. Ultra-high energy efficiency and energy-saving characteristics are the most prominent advantages of fully sealed water permanent magnet synchronous motor. As the permanent magnet rotor is used to replace the electromagnetic excitation system of the traditional asynchronous motor, the copper loss of the rotor is eliminated, and the efficiency of this type of motor generally reaches 90% -98% (IE5 energy efficiency level). Extremely low noise levels and vibration control make water-cooled motors ideal for acoustically demanding environments. Due to the elimination of the main noise source of the cooling fan, the running noise of the hermetically sealed water-cooled motor is reduced by 10-20 dB on average compared with the air-cooled motor of the same class. Excellent environmental adaptability and protection capability enable hermetically sealed water-cooled motors to work reliably in all kinds of harsh conditions. These motors are typically rated IP65, IP68 or higher to protect against the ingress of dust, moisture and chemically aggressive substances.

Non-magnetic synchronous motor

1. Unique innovation, traditional stator mode, innovative rotor design, with dedicated synchronous reluctance controller. 2. Non-magnetic design, the whole machine has no permanent magnet, no power loss, simple and reliable. 3. Higher reliability to minimize operating costs. The temperature rise of the motor is lower, so that the service life of the motor is longer. 4. that control mode is more comprehensive. The motor can adopt position vector control and non-position vector control, which can not only realize precise control, but also realize fuzzy control. 5. The motor is fully controlled, the speed can be reduced to zero, the motor speed is fully controllable, and the functions of low speed and high torque can be better realized. 6. Suitable for most applications, non-magnetic synchronous motors can be used in any application where asynchronous motors are used, such as pumps, fans, compressors, extruders, conveyors and wire drawing machines. 7. Replacement and maintenance are simple. The size of IE non-magnetic synchronous motor is the same as that of asynchronous motor, and there is no need to make too many changes in installation, disassembly and maintenance. 8. Power, voltage, flange, shaft extension size can be customized to meet customer needs. 9. Extensive application scenarios: such as photovoltaic, semiconductor, new energy battery, chemical industry, food, medical treatment, etc.

Brushless DC motor

A brushless DC motor is an electric motor that is powered by a DC power supply, but commutated by a built-in electronic commutator instead of a mechanical brush. By accurately controlling the on-off sequence and direction of the current in the stator winding, the controller makes the stator generate a magnetic field that continuously "rotates" forward. The permanent magnet rotor continuously follows the rotating magnetic field in order to maintain alignment with the magnetic field (i.e., the N and S poles attract each other). Brushless DC motor has fast response, large starting torque, and the performance of providing rated torque from zero speed to rated speed. Brushless DC motor is widely used in automobile, tools, industrial control, automation, aerospace and so on.

Servo motor

1.Extremely high control precision 2. that response speed is fast and the speed regulation range is wide 3. Strong overload capacity, good torque characteristics 4. Smooth operation, good low-speed performance 5. high reliability and good stability 6.High efficiency and energy saving Main application fields: industrial robots, CNC machine tools, electronic manufacturing equipment, packaging machinery, automated production lines, etc.

Main products

Fully sealed water-cooled motor, permanent magnet synchronous motor. Non-magnetic synchronous motor, DC brushless motor, servo motor