Company Introduce

Nefab Group, founded in 1949 and headquartered in Sweden, is a leading global provider of industrial packaging solutions. It currently operates in 38 countries, employs more than 5,000 people and is owned by the Nordgren/Pihl family and FAM AB. Nefab's business scope covers healthcare, semiconductor, data communication, telecommunications, energy, industry, automotive, lithium battery and aerospace industries, focusing on providing customized packaging and logistics solutions. The company is committed to saving environmental resources and customer financial costs by optimizing the supply chain, while ensuring the sustainability and efficiency of its solutions. Since the establishment of its first factory in Wuxi, China in 1997, Nefab has rapidly expanded its business network in China, and now has regional production centers in Dongguan, Langfang, Chongqing and other places, and has set up a nationwide sales and service network. Nefab Dongguan, as the main production base in South China, relies on Nefab's global supply chain system to provide localized design, testing and production support for customers in Dongguan and South China. It is equipped with a professional packaging and testing laboratory, which can simulate the transportation environment, ensure the safety of products in logistics, and escort users in medical and other industries.

Exhibit brands

Exhibits

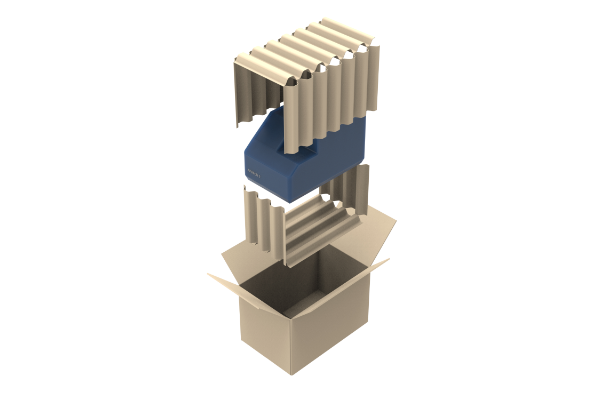

Packaging Solution for Diagnostic equipment

FiberFlute is an innovative corrugated paper cushioning material designed as an eco-friendly packaging solution for high-value precision instruments like medical diagnostic equipment. Made from 100% recyclable materials, it completely replaces virgin plastic foams, delivering excellent cushioning and protection while resisting environmental factors such as humidity. This compact solution significantly reduces packaging volume, enhancing transportation and storage efficiency with outstanding stacking strength, helping clients achieve sustainable supply chain and carbon reduction goals.

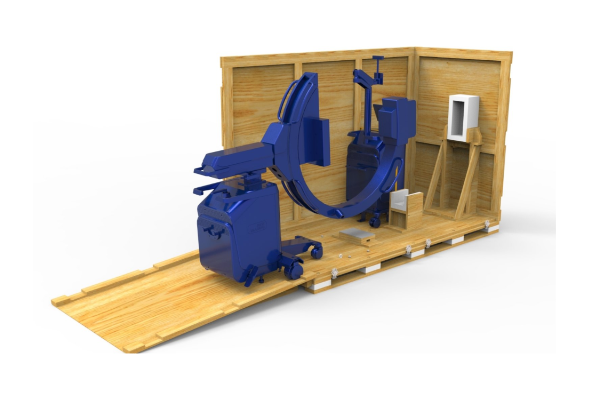

Packaging solution for C-Arm imaging unit by Nefab

In response to the challenges of cost, safety, and efficiency in transporting C-arm equipment, we have introduced an innovative nail-free packaging system. The solution adopts a lightweight, tool-free assembly and disassembly design, combined with a ramp to assist handling, making it easily adaptable to complex scenarios such as narrow hospital corridors. By utilizing EPE cushion pallets and internally customized wooden fixtures, it provides excellent shock absorption and protection while reducing the overall packaging weight by 20%, significantly cutting transportation costs. This integrated design achieves comprehensive optimization of safety, efficiency, and cost-effectiveness.

Corrugated Monitor packaging

Nefab's corrugated monitor packaging for patient monitor delivers high-end protection and sustainability in one design. This 100% plastic-free solution passes ISTA 2A testing, ensures safe transit for large glass screens, and improves efficiency — reducing packaging volume by 34%, increasing transport capacity by 50%, and cutting annual carbon emissions by 211 tons. It also boosts packaging speed by 66% and lowers overall costs by 46%, achieving a balance of protection, environmental responsibility, and operational performance.

Main products

As the world's leading provider of industrial packaging solutions, Nefab focuses on providing customers with customized, sustainable and efficient integrated packaging systems. The company's business covers many frontier industries such as medical, semiconductor, data communication, telecommunications, energy, industrial manufacturing, automobile, lithium battery and aerospace, and provides targeted design and full-link support through in-depth understanding of logistics and protection needs in different fields. With the core goal of optimizing the supply chain, Nefab is committed to saving resources and reducing environmental impact while reducing customer operating costs, so as to achieve the coordinated development of economic benefits and ecological sustainability.