Company Introduce

LAG Machine Tool (Shanghai) Co., Ltd. is a high-tech enterprise dedicated to the intelligent digital transformation of sheet metal processing. It is committed to replacing traditional manual production methods with robotic intelligent production models to achieve intelligent multi-process sheet metal manufacturing. The company’s brand "LAG®" originated in 2012. Through the acquisitions of Italian companies LAG and RAINER, it has realized the integration and localization of Sino-Italian technology, and established integrated platforms in Shanghai and Shandong for R&D, manufacturing, sales, and after-sales service. After more than a decade of development, the company has built an international team capable of providing customers with comprehensive services including smart factory consulting, design, software development, manufacturing, and integration. LAG® operates factories in Shanghai, Italy, Shandong, and other locations. Its product portfolio includes the Robotic Bending Cell (RBC), Robotic Sorting Punching Cell (RSPC), Robotic Sorting Laser Cutting Cell (RSLC), Robotic Welding Cell (RWC), and other serialized products, along with integrated smart factory solutions for sheet metal manufacturing. Its products and services are widely used across numerous industries such as elevators, electrical equipment, engineering machinery, and kitchenware. The company is actively advancing the modularization and standardization of robotic units to gradually achieve batch production. The company emphasizes technological innovation and the conversion of achievements, having obtained over 200 patents and software copyrights. It has also been honored with dozens of awards and recognitions, including "High-Tech Enterprise", "AAA Credit Enterprise", and "Specialized, Refined, Distinctive, and Innovative Enterprise". Leading companies across various sectors, such as Shanghai Siemens, German Hörmann, Hitachi Elevator, and Shandong Inspur, are among its successful cooperation cases. Today, LAG® has become a pioneering player in China’s industry, successfully implementing and applying Italian intelligent sheet metal manufacturing technology in a comprehensive manner.

Exhibit brands

Exhibits

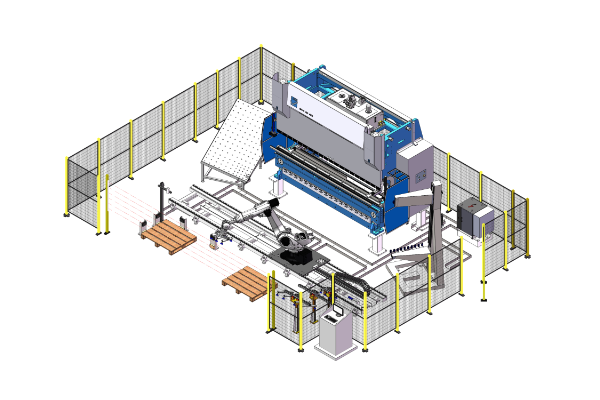

Robot Bending Cell

Features and Advantages Three core algorithms software Synchronized following/ Dynamic aligning/ Dynamic crowning compensation. ALL4ONE--- PC Supervisor integrated software Automatically generates processing tasks, initiates machining cells with one-touch operation, and reports job completion autonomously; integrates with factory MES/ERP systems to enable digitalized production and management. Changeover requires no reprogramming; achieves first-off quality on initial production. High-Mix Low-Volume Production

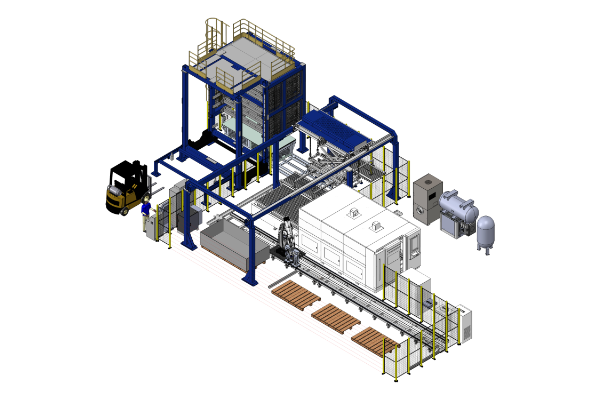

Cartesian Coordinate Robot Sorting Laser Cutting Cell

Features and Advantages BIPODE Octopus Multi-Scenario Gripper; Handles sorting and palletizing in multiple applications. Integrated Auto-Loading/Unloading System; Simultaneously feeds materials and removes residuals—compact and practical. Centralized PC Control; Enables single-command cell initiation.

Main products

Robot Bending Cell Robotized CNC Punching&shear Combi Cell Robotized Laser Cutting Cell Robot Welding Cell Customized&Robotized Smart Sheet Metal Work Shops