Company Introduce

Shenzhen Yingshuoer Photoelectric Technology Co., Ltd. is a professional manufacturer dedicated to the application of photoelectric sensor technology and the provision of control technology solutions, specializing in the production and customization of infrared light curtains for various purposes. Provide three series of infrared light curtain products: safety light curtain, detection light curtain and measurement light curtain products. Detection and measurement light curtain series products are widely used in non-contact measurement and detection, automatic control and other fields in various industries to achieve the purpose of automatic measurement or automatic production. Safety light curtain (photoelectric protector) series products are widely used in manufacturing and processing industries, and are used together with mechanical equipment to protect the personal safety of operators. The infrared protection device is installed in the places where the operation is dangerous, such as the punch, the hydraulic press or the automation equipment, and the automatic shutdown can be controlled to achieve the purpose of protecting the personal safety when the body of a person is detected to enter the dangerous area. In terms of product innovation, the company adopts new international safety standards and domestic industry standards, adopts new safety control techniques, constantly enriches product categories and improves product performance. In terms of production management, the company strictly follows the IS02000 quality management system, carries out strict testing and inspection on raw material procurement and product delivery, and pursues high reliability of products and high customer satisfaction.

Exhibit brands

Exhibits

Safety grating: ES50 ultra-thin series

ES50 ultra-thin safety grating: exclusive protection advantages for semiconductor and 3C electronics industry ES50 ultra-thin safety grating has become an ideal protection choice for semiconductor equipment and 3C electronic equipment production scenarios by precisely adapting to the core design of industry demand, and has built a strong safety barrier for precision manufacturing. Extremely compact design for small installation spaces Semiconductor wafer processing equipment, 3C electronic precision assembly machine and other scenes, the internal structure is compact and the installation space is limited. ES50 series, with 13mm ultra-thin thickness and 13 * 26MM slim section size, can be easily embedded into the narrow installation position reserved by the equipment without changing the original structural design of the equipment, which perfectly meets the layout requirements of space-sensitive equipment such as airtight detection system and vacuum cavity, and does not affect the airtight integrity and operation accuracy of the equipment. Multiple security guarantees to protect the precise production process Equipped with real-time self-check function, it can monitor the operation status of equipment in the whole process, detect abnormalities in time and trigger protection, so as to avoid damage to high-priced materials such as wafers and chips caused by grating failure. The imported SCM control circuit is equipped with short circuit, overcurrent and reverse connection protection. With the optical synchronization design and separate power supply mode, it can effectively resist electromagnetic interference in the industrial environment and ensure stable operation in the workshop where high-frequency electronic equipment is concentrated. Through CE/FCC double international certification, it meets the stringent safety standards of semiconductor and 3C industries, and provides reliable protection for operators and precision equipment. Adapt to industry characteristics and improve production safety efficiency Semiconductor and 3C electronic production environments require high equipment compatibility and protection accuracy. The non-interference design of ES50 series can be flexibly linked with the PLC system to meet the protection requirements of chip process, circuit board welding, electronic component assembly and other links, which not only prevents personnel from entering dangerous areas by mistake, but also does not affect the high-speed operation of the automatic production line. Its convenient installation and stable performance can reduce the time of equipment shutdown and commissioning, and help enterprises achieve double improvement of safety and efficiency.

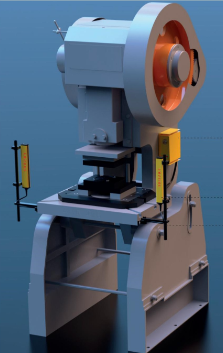

ET30 Punch Infrared Protector

The ET30 punch press infrared protector is designed to provide non-contact safety protection for punching equipment. Quick response, strong anti-interference, convenient installation, suitable for all kinds of punches, in line with international safety standards, precise protection of operation safety, to ensure efficient operation of production.

XD-30 series three-color warning light

Instruction manual of three-layer three-color lamp Scope of application: automatic assembly line, automation equipment, security inspection equipment, led packaging equipment, alarm system, SMT equipment, CNC machine tools, CNC, carving machine, CNC milling machine, industrial and mining equipment, etc. Performance characteristics High-brightness LED patch, high brightness, large angle 1, modular design, good heat dissipation, exquisite and beautiful structure, unique and innovative appearance, left and right folding 90; 2, the use of high-brightness LED chip, high brightness, large angle, low thermal resistance, color area concentration, ultra-low light decay process, ultra-long life 3, the use of high-quality driver board, custom IC sound buzzer, the sound can reach 95dB, comprehensive protection of the overall life of lamps;

Main products

Shenzhen Yingshuoer Photoelectric Technology Co., Ltd. is a professional manufacturer dedicated to the application of photoelectric sensor technology and the provision of control technology solutions, specializing in the production and customization of infrared light curtains for various purposes. Provide three series of infrared light curtain products: safety light curtain, detection light curtain and measurement light curtain products.