Company Introduce

Lihua is a high-tech enterprise specializing in the research and development and production of induction heating automation. For 19 years, we have been committed to the research and production of high-end intelligent induction heating automation equipment, which has been applied in multiple metal induction heating fields. We have been awarded national high-tech enterprise and more than 60 patents, and can efficiently provide the best intelligent solutions for your special process needs. It is a member unit of the China Welding Association, Heat Treatment Industry Association, and Guangdong Heat Treatment Society. It has a large modern garden style factory with an area of 8000 square meters, and has continuously set a leading sales record for high-frequency brazing equipment. Since 2005, Lihua has gone through 8 production process optimizations, 5 updates and iterations of production machinery and equipment, modern lean production management mode, strict quality requirements and inspection standards, which have always been its pursuit.

Exhibit brands

Exhibits

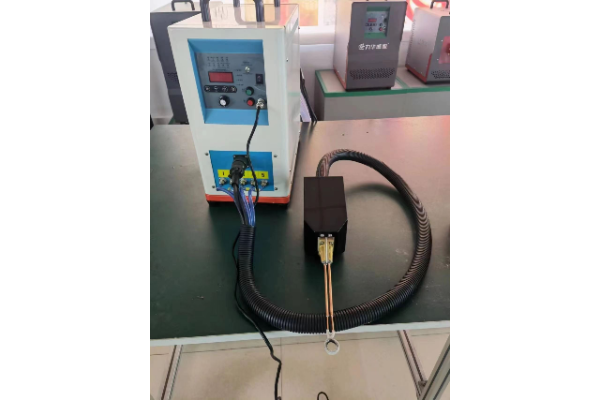

Hand-held high frequency induction welding heating equipment 35 kw

Lihua's handheld transformer is small in size and light in weight. The unique waterproof technology and materials make the handheld transformer not afraid of water, resistant to weak acid, weak alkali and high temperature. After starting up, the power can be accurately adjusted only through the host panel. The light and stable operating handle and detachable sling improve the convenience of operation. The flexible output connection cable is easy and dexterous to approach and work, convenient to operate, and improves the use efficiency.

Hand-held ultra-high frequency induction welding equipment 10 kw

Lihua's handheld transformer is small in size and light in weight. The unique waterproof technology and materials make the handheld transformer not afraid of water, resistant to weak acid, weak alkali and high temperature. After starting up, the power can be accurately adjusted only through the host panel. The light and stable operating handle and detachable sling improve the convenience of operation. The flexible output connection cable is easy and dexterous to approach and work, convenient to operate, and improves the use efficiency.

High frequency induction heating equipment 40 kw split machine

High frequency heating adopts the third generation frequency conversion technology to ensure that the machine can work continuously for 24 hours under the maximum power, and has the function of constant current and constant power control to improve the heating efficiency. Uniform heating, energy consumption is only 20% -50% of the high frequency of the electronic tube, to achieve the best effect of energy saving: no noise, low energy consumption, environmental protection, simple operation of numerical control design

Ultra-high frequency induction heating equipment 6 kw

Ultra-high frequency induction heating equipment has the characteristics of high frequency, small size, light weight, energy saving, firm welding point, beautiful and delicate. The equipment adopts advanced technologies such as soft switching resonance double regulation and frequency automatic tracking system, MOSFET device and unique frequency conversion technology, which makes the equipment run more stably and have higher heating efficiency. At the same time, because the equipment has no open fire production, it is safe to use, and it is environmentally friendly and pollution-free, so it is widely used in metal glasses manufacturing industry, connector welding in electrical and electronic industry, non-contact welding in small relays, high-pressure welding in refrigeration industry, welding between parts in jewelry industry and welding in metal jewelry and process manufacturing industry.

Double-station automatic angle-swinging external polis machine

This double-station automatic swing angle polishing machine is an efficient polishing equipment specially designed for hardware products such as cups, pots and kettles. It solves the industry pain points of low efficiency, uneven precision and high cost of manual polishing with automatic design, and meets the polishing needs of large-scale production of kitchen and bathroom hardware products. Equipped with dual-station synchronous operation structure and intelligent automatic swing angle system, the equipment can flexibly adjust the polishing angle and process parameters, easily meet the diversified polishing requirements of different specifications and shapes of cups, pots and pans, and realize one-stop processing from rough polishing to fine polishing. At the same time, the equipment adopts high-efficiency and energy-saving power configuration, which reduces energy consumption while improving production efficiency, achieves uniform and stable polishing effect, greatly reduces labor input, and provides reliable automation solutions for kitchen and bathroom hardware manufacturing enterprises to achieve cost reduction and efficiency enhancement and improve product surface processing quality.

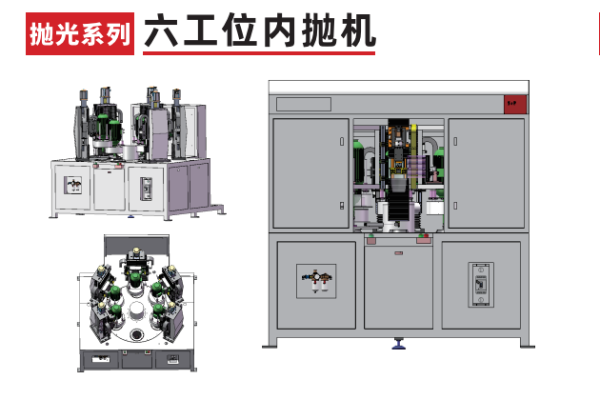

Six-station internal polis machine

This six-station internal polishing machine is a high-capacity automatic polishing equipment specially designed for kitchen and bathroom hardware products such as cups, pots and kettles, which accurately solves the industry pain points of low efficiency, unstable quality and high cost of manual polishing. The equipment adopts six-station parallel operation design, which can synchronously process multiple workpieces. Combined with the adaptive polishing angle adjustment system, it can flexibly adapt to the polishing requirements of the inner surface of cups, pots and pans with different calibers and depths, and can be completed at one time from rough polishing to fine polishing. Its high-efficiency and energy-saving power system and intelligent speed control technology can greatly improve production efficiency while significantly reducing energy consumption, and the polishing effect is uniform, smooth and consistent. Through the whole process of automatic operation, the equipment not only reduces manual dependence, but also stably guarantees the surface processing quality of products, which is the core equipment for kitchen and sanitary hardware manufacturing enterprises to achieve large-scale production, cost reduction and efficiency enhancement.

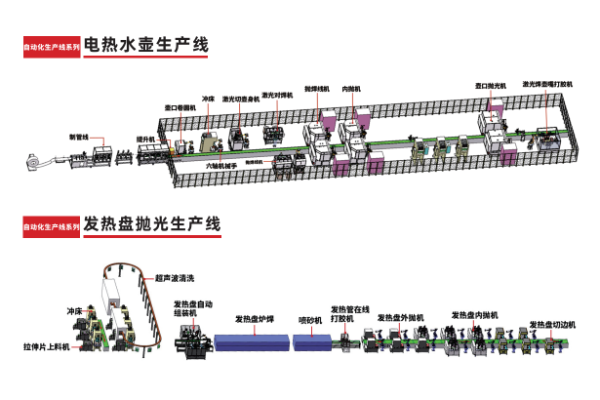

Full-automatic kettle whole line automation equipment

This set of automatic kettle line automation equipment is a one-stop intelligent production solution tailored for household appliance kettle manufacturing enterprises, which realizes the whole process of unmanned operation from raw materials entering the factory to the formation of finished kettles. The whole line integrates core process modules such as pipe making, stamping, laser cutting and welding, multi-station polishing, spout welding and sealing, and seamlessly connects each process with industrial robots through intelligent conveying system, so that the processing and assembly of key components such as kettle body and heating plate can be completed without manual intervention. The equipment has high flexibility and adaptability, and can quickly switch the production parameters of kettles with different specifications to meet the diversified market demand. At the same time, it adopts high-efficiency and energy-saving power configuration and intelligent consumption control technology to effectively reduce the comprehensive energy consumption and labor cost on the basis of ensuring the production efficiency and product quality stability. It solves the industry pain points of traditional production line process decentralization, high artificial dependence and large quality fluctuation from the root, and builds up efficient, intelligent and low-cost large-scale production capacity for household appliances kettle manufacturing enterprises, which is the core equipment to build "black lamp factory".

Main products

High frequency, medium frequency, and ultra-high frequency heating and welding equipment, handheld high-frequency and ultra-high frequency heating and welding equipment, fully automated equipment, laser welding equipment, non-standard customization