Company Introduce

Dongguan Liwei Metal Technology Co. , Ltd. originated from Shenzhen Tiancheng Heat Treatment Plant 1999-2016. In June 2016, it moved to 229 Jin Lang South Road, Dalang, Dongguan, Dongguan. The 2023 company moved and upgraded to 81 Shahe Road, Shabu Industrial Zone, Dalang, Dongguan, Dongguan. The company specializes in stainless steel bright heat treatment: quenching, passivation, cryogenic, demagnetization, solid solution, aging, coercive force, laser welding, copper brazing, nickel brazing, silver brazing metal materials trade and technical advice. The company has 8 sets of bright furnace, cryogenic furnace, high temperature tempering furnace, low temperature tempering furnace, laser welding machine, cold welding machine, argon arc welding machine, the testing equipment includes Rockwell hardness tester, Rockwell surface hardness tester, Vickers hardness tester, torsion tester, metallographic microscope, etc. . Liwei company to do not Treasure Gold and Jade, and loyal to treasure, quality first, customer service business philosophy, adhere to, to provide customers with high-quality, homogeneous, quality products and service policy, production and processing in strict accordance with international practices, and formed an effective testing and acceptance system. We will, as always, adhere to the policy of being pragmatic and honest, striving for perfection, customer first, and reputation first. We will work hard to achieve win-win with our customers, serve the public, and return to the society only for the sake of having a dream, be aggressive. Only for the promise, we will not hesitate to make unremitting efforts

Exhibit brands

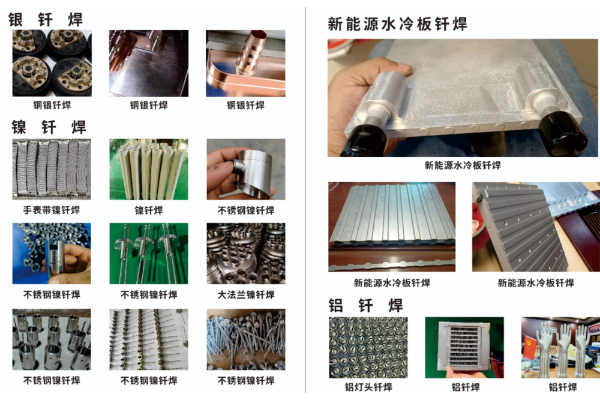

Main products

Brazing of copper,Aluminum brazing,Silver brazing,Nickel brazing. Bright Austenitic stainless steel, annealing, cleaning, passivation. Bright Martensitic stainless steel, quenched.