The Essential Guide To CNC Milling Machines

【Introduction】 This article explains CNC Milling Machines, how they work, how they compare to CNC Lathes, and when to use them.

For those who may be a new entrant to the industry and would need a refresher, this article explains CNC Milling Machines, how they work, how they compare to CNC Lathes, and when to use such CNC machine tools.

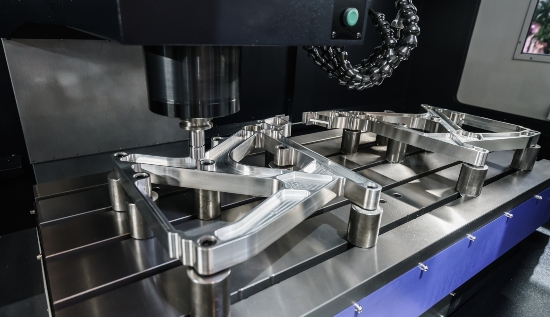

Focused on milling - the process of machining using rotating tools to gradually remove material from a workpiece - CNC milling machines are a mainstay for factories around the world. These machine tools make use of a variety of cutting tools along one or more axes to remove material from a workpiece through mechanical means.

CNC milling machines are often used in a variety of manufacturing industries: from industries like aerospace, shipping, automobiles, and oil drilling/pumping and refining, to medical, FMC manufacturing, and precision engineering sectors.

Also called CNC Machining Centers, the more advanced CNC milling machines can operate along multiple-axis. These may be fitted with automatic tool changers, advanced machine coolant systems, pallet changers, and advanced software to improve the efficiency and accuracy of machining processes.

In this article, we will be looking at the many different aspects of a CNC milling machine/machining center.

What CNC Milling Machines Are

CNC milling machines are machine-operated cutting tools that are programmed and managed by computer numerical control (CNC) systems to accurately remove materials from a workpiece. The end result of the machining process is a specific part or product that is created using a computer aided design (CAD) software.

These machine tools are normally equipped with a main spindle and three-linear-axes to position or move the part to be machined. More advanced versions may have a 4th or 5th rotational axis to allow for more precise shapes of varying dimensions and sizes to be machined.

CNC milling machines normally employ a process of material cutting termed milling or machining – the milling process involves securing a piece of pre-shaped material (also known as the workpiece) to a fixture attached to a platform in the milling machine. A rapidly rotating tool (or a series of interchangeable tools) is then applied to the material to remove small chips of the material until the desired shape for the part is achieved.

Depending on the material used for the part, as well as the complexity of the machined part, varying axes, cutting head speeds, and feed rates may be applied.

Milling is normally used to machine parts that are not symmetrical from an axial perspective. These parts may have unique curvatures or surface contours, which may require a combination of drilling and tapping, grooves, slots, recesses, pockets and holes to work on them. They may also form parts of the tooling for other manufacturing processes – for example in the fabrication of 3D moulds.

Features of Advanced CNC Milling Machines

In the past, milling machines were manually operated. Operators had to use a combination of machines with different tools to machine a more complex part or product. Or they had to use various settings on one machine just to complete the job.

With the advancement of technology such as CNC and automatic tool changers (ATCs), greater efficiency, flexibility and speed can be achieved – even for more convoluted parts. The provision of digital readouts and measuring systems has also improved the accuracy of CNC machining processes.

With the advancement of technology such as CNC and automatic tool changers (ATCs), greater efficiency, flexibility and speed can be achieved - even for more convoluted parts. The provision of digital readouts and measuring systems has also improved the accuracy of CNC machining processes.

To cater to manufacturers that require the flexibility of "High Mix, Low Volume” (HML) or "small batch" production, CNC machining centers can be fitted with Pallet Changers or other automation solutions to form part of a flexible manufacturing cell (FMC) or flexible manufacturing system (FMS). This allows such machines to cater to a wide variety of machining demands and needs.

How CNC Milling Machines Work

The general principle for a CNC milling machine or CNC machining center is that the part to be machined is clamped on top of the machine table. It could be clamped directly on the table itself, or held in place by a vice or fixture.

The spindle (moving section) including the cutting tool is then either vertically or horizontally positioned. In that configuration, the tool can reach various X-Y-Z positions on the workpiece and commence cutting and shaping actions. As it does so, the workpiece or part may either be fixed, mounted, or moved/positioned by the table in a linear direction to the spindle with the cutting tool. This allows the material to be removed according to the desired shape needed for the machined part. A CNC milling machine may either be horizontal or vertical.

CNC Milling Machine vs CNC Lathe

While CNC milling machines are machine tools just like a CNC lathe, both tools operate quite differently.

For a CNC milling machine (aka CNC machining center), the workpiece is fixed or mounted in position using a vice or fixture while the cutting tool is manœuvred on top of or around the piece. Material is then gradually removed using cutting tools or drills which rotate at high speed with varying feed rates along two or more axes.

In the case of a CNC lathe (aka CNC turning center), however, the workpiece (usually cylindrical) is mounted on a rotating chuck or on the main spindle. It is then "turned" (hence, the name turning center) or rotated along a main axis while the cutting tool located in a rotational or positioning turret would move in a parallel direction to the piece. Material is then removed using stationery cutting tools.

Thus, a CNC milling machine uses a spinning tool with a stationery workpiece, whereas a CNC lathe would involve pinning the material to be worked on by a stationery cutting tool.

Milling Tools Used by CNC Milling Machines

In general, CNC milling machines can deploy a wide range of cutting and shaping tools. These tools help to remove material by virtue of how they move within the machine or directly from the cutter’s shape. These may include the following:

lEnd mills, flat or ballnose, straight or form tools

lFace mills

lDrills, U-drills, spiral borer

lTaps

lReamers

lTool holders and hydraulic tool holders, shrink-fit or press-fit holders

Finding the Right CNC Milling Machine

There are many different variations and types of CNC milling machines - from simple two- to three-axis machines to multi-axis CNC machining centers. Generally speaking, the main variations are either vertical or horizontal machining centers. When you consider the right CNC milling machine for your machining needs, it is useful to consider your specific requirements in terms of your machined part dimensions, complexity of its shape and design, need for accuracy, as well as the machine longevity and stability.