The Rise of Electric and Hybrid Drive Systems in Metal Forming at Metal Forming Expo 2025

【Introduction】 The Rise of Electric and Hybrid Drive Systems in Metal Forming at Metal Forming Expo 2025

The Rise of Electric and Hybrid Drive Systems in Metal Forming at Metal Forming Expo 2025

At ITES, we are excited to announce the upcoming Metal Forming Expo 2025, where industry leaders will gather to explore the latest advancements in metal forming technology. One of the most significant trends shaping the future of this sector is the rise of electric and hybrid drive systems in metal forming processes. As we delve into this topic, we aim to highlight the benefits and innovations that these systems bring to manufacturers.

Electric and Hybrid Drive Systems

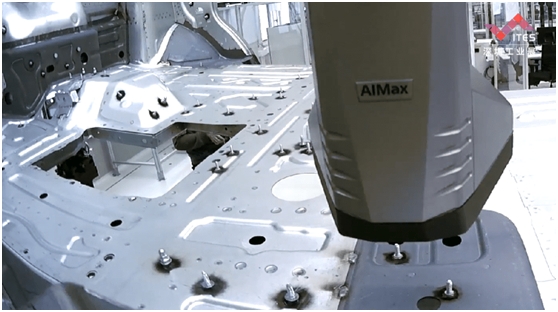

Electric and hybrid drive systems have gained traction in various manufacturing fields, including metal forming. These systems utilize electric motors alongside traditional mechanical drives to enhance productivity and efficiency. At the Metal Forming Expo 2025, we will showcase how these advanced drive systems contribute to more precise control over metal forming operations. By providing instant torque and adjustable speed, electric and hybrid drives can significantly reduce energy consumption and operational costs. We believe that manufacturers who adopt these technologies will not only improve their production capabilities but also lower their environmental impact.

Benefits of Electric and Hybrid Systems in Metal Forming

The transition to electric and hybrid drive systems offers numerous advantages for companies involved in metal forming. First and foremost, these systems provide enhanced energy efficiency, which is crucial in today’s competitive landscape. With rising energy costs and increasing pressure to reduce carbon footprints, investing in electric drive technology becomes a strategic move for manufacturers. Furthermore, electric and hybrid systems require less maintenance compared to traditional hydraulic systems, resulting in reduced downtime and improved reliability. Our goal at the Metal Forming Expo 2025 is to demonstrate how these benefits can lead to higher profitability and sustainability for manufacturers.

The Future of Metal Forming with Electric Drives

As we look ahead to the future of metal forming, the integration of electric and hybrid drive systems seems inevitable. This transition aligns with the broader trend of automation and smart manufacturing that is revolutionizing the industry. At the Metal Forming Expo 2025, we will host discussions and presentations featuring experts who will share insights into how electric drives are transforming metal forming processes. We are eager to showcase real-world applications and case studies that illustrate the successful implementation of these technologies. Our exhibitors will present innovative solutions that harness the power of electric and hybrid drives, setting the stage for a more efficient and sustainable manufacturing environment.

Conclusion

In conclusion, the Metal Forming Expo 2025 organized by ITESpresents a unique opportunity to explore the rise of electric and hybrid drive systems in metal forming. As manufacturers increasingly recognize the advantages of these technologies—such as energy efficiency, reduced maintenance costs, and enhanced precision—we are committed to facilitating conversations that inspire innovation within the industry. Join us at the Metal Forming Expo 2025 to discover how electric and hybrid drive systems can reshape the future of metal forming.