How Intelligent Conveying Systems Improve Efficiency in Multi-Variety, Small-Batch Production

【Introduction】 How Intelligent Conveying Systems Improve Efficiency in Multi-Variety, Small-Batch Production

Modern manufacturing faces a persistent challenge: achieving lean efficiency amidst increasing product customization and shorter lead times. Multi-variety, small-batch production runs demand a fundamental shift from rigid, linear lines to flexible, adaptive systems. At the heart of this shift is the intelligent conveying system, a category where specialized manufacturers are providing pivotal solutions. We will explore the function of these systems and how engaging with a knowledgeable manufacturer of conveying and seasoning systems can address specific production hurdles.

The Functional Role of Flexible Conveying Technology

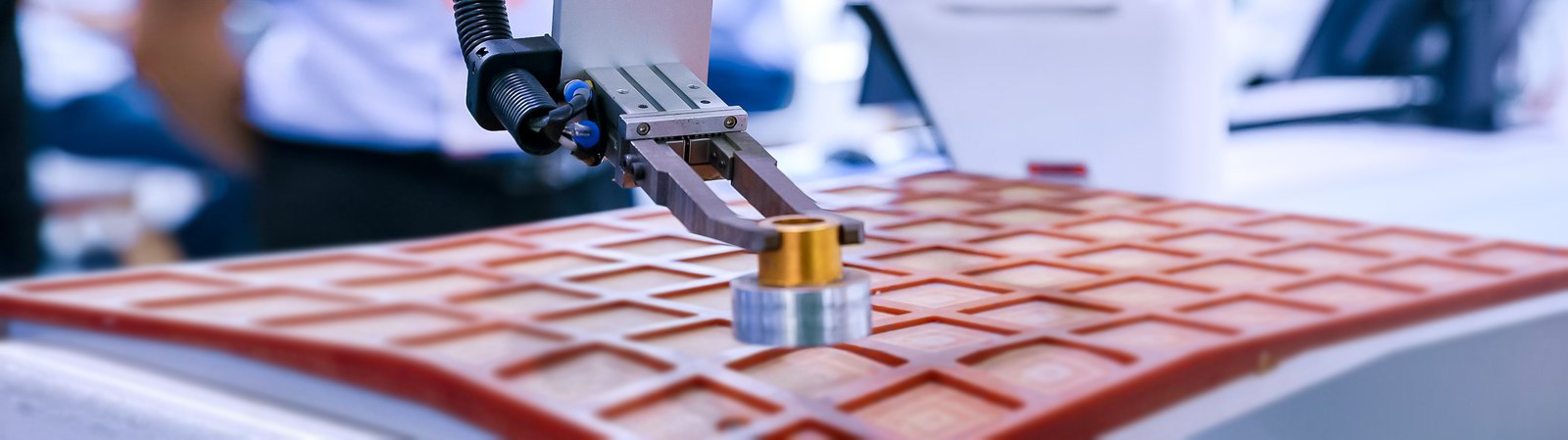

The core task of an intelligent conveying system in a high-mix, low-volume environment is to enable fluid material flow without constant manual reconfiguration. Unlike fixed conveyors designed for a single product, these systems incorporate modularity, programmable logic, and often, integrated vision or RFID tracking. This allows raw materials, semi-finished, and finished goods to be automatically routed, sorted, and delivered to the correct workstation based on real-time production data. The system acts as the central nervous system of the workshop, coordinating disparate operations. By automating the grasping, positioning, and transportation of varied components, it reduces non-value-added handling time, minimizes errors, and crucially, cuts the changeover time between different product batches. This adaptability is the primary efficiency gain offered by a proficient conveying system manufacturer.

Capabilities of Chinese System Integrators and Suppliers

The market here has evolved to meet this need for flexibility. A forward-thinking manufacturer of conveying and seasoning systems today offers more than hardware; they provide integrated material handling solutions. Their expertise lies in understanding the entire workflow—from warehouse interfacing to final packaging—and designing a system that is both scalable and reconfigurable. Key differentiators include the ability to integrate with existing machinery, implement warehouse management software interfaces, and design modular components like flexible loading/unloading arms and adaptive vibratory feeders. For a production manager, the advantage of partnering with such a conveying system manufacturer is the move towards a truly interconnected production cell, where material flow is synchronized with assembly pace, directly supporting efficient small-batch execution.

Seeing Integrated Solutions at a Technical Exhibition

Evaluating such integrated systems requires seeing them in a applied context. This is where platforms dedicated to advanced manufacturing gain their relevance. At ITES China, a dedicated zone for Intelligent Conveying & Loading/Unloading Solutions presents these concepts in tangible form. This segment focuses precisely on smart material transfer within unmanned production lines for precision components, directly addressing the high-mix, low-volume scenario.

For any professional considering an upgrade, ITES China provides a direct channel to multiple expert conveying system manufacturer exhibitors. The exhibition floor allows visitors to examine logistics conveying equipment, assess warehouse integration solutions, and compare the operational nuances of different flexible loading/unloading equipment. Live displays of vibratory feeders, precision feeder controllers, and linked packaging machinery illustrate how discrete units function as a cohesive whole. Engaging with engineers from a manufacturer of conveying and seasoning systems on-site facilitates discussions about specific layout challenges, throughput requirements, and control system compatibility. This direct interaction is a necessary step in moving from concept to a viable, tailored system proposal.

The transition to agile, small-batch production is greatly supported by intelligent material handling. The technical capability to create modular, software-driven conveying systems exists within the current market, with specialized suppliers offering the needed integration expertise. Conclusive evaluation of these conveying system manufacturer proposals, however, benefits from direct observation and technical dialogue. Events like ITES China consolidate this specialized field, offering a practical environment to assess solutions that can transform production flexibility and efficiency. We provide this platform to facilitate the connections that drive such operational advancements forward.