How Machining Centers Improve Precision for Complex Part Geometries

【Introduction】 How Machining Centers Improve Precision for Complex Part Geometries

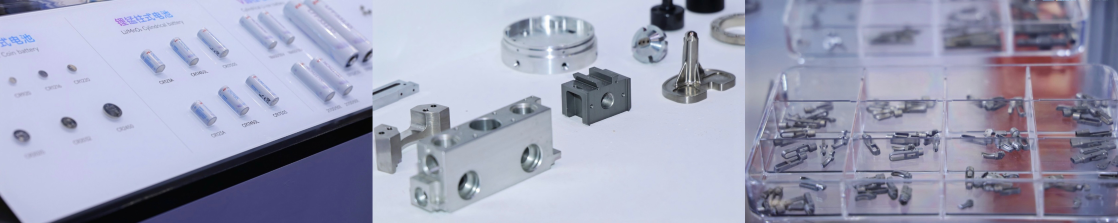

As manufacturers continue to design parts with tighter tolerances and more intricate shapes, precision machining has become a practical requirement rather than a technical preference. We have observed that complex geometries—such as deep cavities, multi-angled surfaces, and integrated functional features—place higher demands on equipment stability, programming accuracy, and process coordination. In this context, the China CNC machining center ecosystem has gained attention for its ability to support consistent precision while remaining adaptable to evolving design requirements. Supported by mature industrial clusters, standardized quality systems, and responsive supplier networks, this manufacturing environment allows precision objectives to be addressed efficiently across both prototyping and series production. These conditions are particularly relevant for industries that require frequent design iteration without compromising dimensional control.

Multi-Axis Control and Process Stability in Complex Machining

From a technical perspective, machining centers improve geometric precision mainly through coordinated multi-axis movement and stable process execution. By enabling synchronized positioning across multiple axes, machining centers reduce repeated setup and manual alignment, which helps limit cumulative deviation on complex surfaces. In our daily observations of supplier capabilities, many solutions associated with a CNC machining center in China focus on optimizing tool paths, spindle rigidity, and thermal management to maintain accuracy over extended machining cycles. This approach is especially valuable for parts with intersecting contours, internal features, or variable wall thicknesses. When combined with experienced operators and structured inspection procedures, machining centers help ensure that complex geometries remain aligned with original design intent throughout batch production.

Supply Chain Collaboration and Equipment Innovation in China

Precision machining outcomes are shaped not only by equipment performance but also by how effectively the surrounding supply chain supports the process. Within the Chinese manufacturing landscape, machining centers benefit from localized component sourcing, timely technical service, and ongoing equipment refinement driven by application feedback. These factors contribute to predictable delivery schedules, reduced risk of delays, and smoother system integration for global buyers sourcing from a China CNC machining center environment. Additionally, careful coordination with local suppliers and quality control partners ensures that materials and components meet exact specifications, which is essential for achieving repeatable results in complex part geometries. At ITES China, we actively showcase these capabilities, demonstrating how advanced machining centers and integrated supply chain solutions work together to maintain precision. We also see increasing attention given to automation compatibility, digital monitoring, and material versatility, which further strengthen consistency when machining intricate features. Our platform highlights these developments through application-focused communication, providing engineers and procurement teams with practical case studies, operational guidance, and detailed insights into process optimization, helping them fully leverage available machining capabilities for real-world production requirements.

Conclusion: Connecting Precision Manufacturing with Industry Exchange

Precision machining for complex geometries continues to evolve through both technological improvement and structured industry collaboration. As we connect manufacturers, solution providers, and end users, we emphasize practical application insight rather than generalized performance claims. Through ITES China, we present machining centers, tooling systems, automation solutions, and digital manufacturing technologies within a focused industrial context. At ITES Shenzhen, visitors can review real machining scenarios, engage with exhibitors on process control strategies, and assess how machining centers support precision across different part geometries. By combining technical understanding with supply chain visibility, we aim to facilitate informed evaluation and encourage constructive exchange within the precision manufacturing community.