Choosing the Right Camera, Lens, and Lighting for Industrial Vision Systems

【Introduction】 Choosing the Right Camera, Lens, and Lighting for Industrial Vision Systems

Assembling a reliable industrial vision system is an exercise in component synergy. The performance of the system depends on the coordinated selection of its core parts: the camera, the lens, and the lighting. An mismatch between these elements can compromise detection accuracy, even with advanced software. At ITES Shenzhen, we see this technical triad as the foundation of effective machine vision, a principle reflected in the specialized offerings from manufacturers. This guide outlines the function of each component, discusses the integrated supply chain supporting their production, and presents a forum where these technologies can be evaluated in unison for specific industrial tasks.

.png)

Core Component Functions: Capturing, Focusing, and Illuminating

Each element in the vision chain addresses a distinct physical requirement. The industrial vision systems cameras act as the sensor, converting light into digital data. Selecting a camera involves analyzing parameters like resolution, which defines detail clarity; sensor size, which influences the field of view; and frame rate, which determines suitability for high-speed lines. The lens is the optical interface between the camera and the target. Its quality dictates image sharpness and distortion control. Key lens specifications include focal length, which sets magnification and working distance, and aperture, which affects depth of field and light gathering. Lighting is not merely illumination but a tool for contrast enhancement. Proper lighting techniques—such as back lighting, dark field, or structured light—are employed to highlight features of interest, like edges, surface textures, or defects, making them distinctly visible to the industrial vision systems cameras.

Integration and Sourcing from Specialized Suppliers

The effectiveness of industrial vision systems hinges on the seamless integration of these components. Chinese suppliers have developed capabilities across this entire value chain. Manufacturers of industrial vision systems cameras offer a range from standard area-scan models to specialized line-scan, infrared, or high-speed variants. This is complemented by a robust ecosystem of optical lens producers and specialized lighting solution firms offering LED arrays, light guides, and controllers. The supply chain advantage lies in this concentration, which facilitates coordinated development. A system integrator can source matched components—where a lens is optically corrected for a specific sensor size, and lighting is tuned to a particular wavelength—from collaborating suppliers. This reduces compatibility risks and streamlines the assembly of a coherent industrial vision systems package.

A Targeted Environment for System Evaluation at ITES Shenzhen

Theoretical knowledge of components must transition to practical validation against real inspection challenges. The Machine Vision Applications and Inspection Equipment section at ITES Shenzhen provides this critical environment. This zone is purpose-built for comparing technologies and discussing integration strategies directly with experts. The exhibition is organized to address complete inspection workflows. A primary highlight is the demonstration of turnkey vision integration solutions. These displays show how cameras, lenses, lighting, and software platforms are combined to perform specific tasks like high-speed defect detection, micron-level dimensional measurement, and complex appearance inspection on production lines.

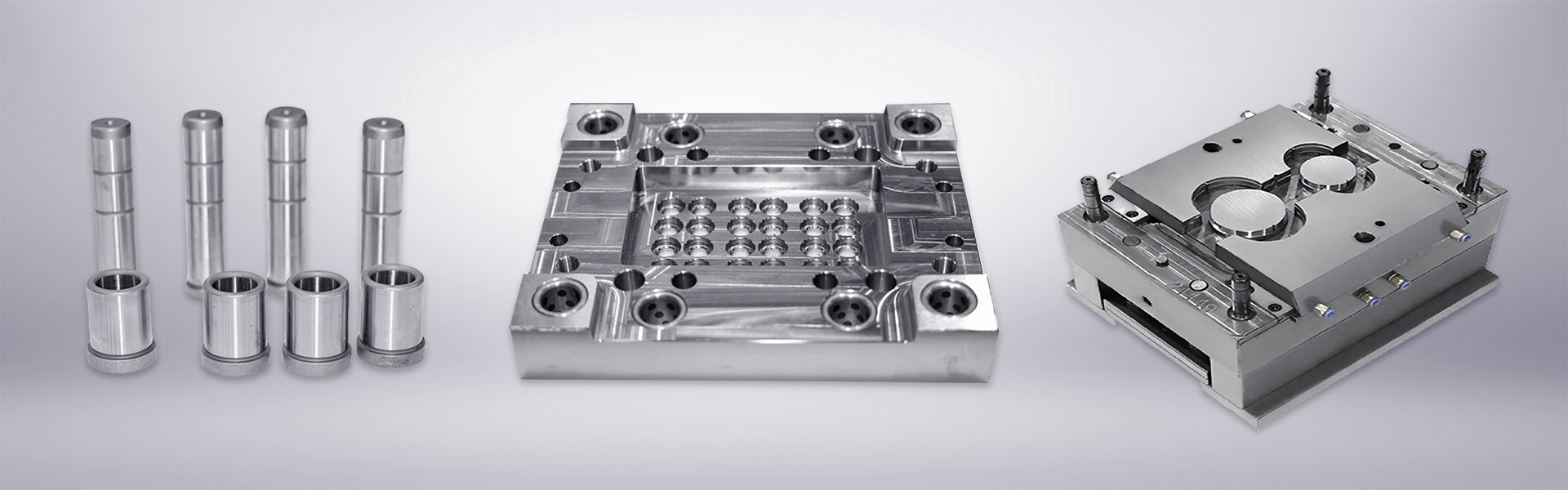

The exhibitors represent the full spectrum of the vision technology stack. ITES Shenzhen gathers these entities in one location, allowing visitors to engage with manufacturers of industrial vision systems cameras, precision optics, and advanced lighting. Alongside them are providers of vision software platforms, code readers, and related components. This collective presence enables a holistic assessment. Professionals can evaluate the interoperability of hardware from different vendors or explore complete inspection equipment packages. The exhibits are demonstrated with direct application to industry needs, showing how these industrial vision systems serve precision component production in the 3C/electronics, semiconductor, new energy lithium battery, automotive parts, and machinery manufacturing sectors.

Specifying the camera, lens, and lighting for an industrial vision application is a technical process that balances optical laws with production line constraints. The availability of specialized manufacturers within a connected supply chain supports the efficient configuration of reliable industrial vision systems. For engineers and decision-makers responsible for implementing or upgrading inspection stations, the Machine Vision Applications and Inspection Equipment section at ITES Shenzhen offers a necessary opportunity for hands-on analysis. We facilitate this convergence of technology and application, providing a platform where component selection moves from datasheet specifications to proven solutions for quality control and automated guidance tasks.