Optical Sorting Systems for High-Speed Screening of Precision Components

【Introduction】 Optical Sorting Systems for High-Speed Screening of Precision Components

In modern manufacturing, ensuring the integrity of components before assembly is a non-negotiable requirement. Optical sorting system technology has become a fundamental method for this task, performing rapid, non-contact inspection and physical separation based on defined criteria. For industries where part consistency directly affects product performance and safety, these systems provide a critical quality gate. At ITES China, we view the adoption of this technology as a clear step toward automated quality assurance. This article explains how these systems function, outlines the manufacturing landscape for them, and details where to examine their capabilities alongside complementary vision technologies.

.png)

The Operational Framework of an Optical Sorting System

A functional optical sorting system integrates several advanced technologies into a coordinated process. The operation begins with a consistent feeding mechanism that presents components to an inspection area. Here, high-resolution cameras, often paired with specialized lighting, capture detailed images of each part. Sophisticated software then analyzes these images in real-time, applying algorithms to detect defects, verify dimensions, or check for correct color and surface finish. This decision-making layer is what transforms a simple imaging station into an optical sorting system. Following inspection, a precise rejection mechanism—such as an air jet, mechanical pusher, or diverter—physically removes any non-conforming items from the production stream. The entire cycle occurs at high speeds, enabling 100% inspection without creating a bottleneck.

Manufacturing Capabilities and Supply Chain Integration

The production of reliable optical sorting system units requires expertise in mechanical design, precision optics, software development, and systems integration. A growing number of specialized optical sorting system manufacturers in China have developed this multidisciplinary competency. Their development is supported by a mature local supply chain for key components like industrial cameras, lenses, LED lighting arrays, and precision actuators. This vertical integration allows optical sorting system manufacturers to prototype and build systems with shorter lead times and a focus on specific application challenges. The advantage for global buyers includes access to customizable solutions that can be tailored for unique component geometries or specific defect types, moving beyond standard off-the-shelf offerings.

A Central Hub for Vision and Sorting Technology at ITES China

Selecting and implementing an optical sorting system benefits from direct observation and technical consultation. The Machine Vision Applications and Inspection Equipment section at ITES China serves as this essential hub. This zone provides a concentrated view of the entire technology stack, from core components to complete integrated solutions. The exhibition is designed to connect engineering challenges with practical equipment. A key highlight is the live demonstration of integrated systems. Visitors can see operational units performing actual sorting tasks, which allows for assessment of throughput, accuracy, and mechanical integration in a context that mirrors factory conditions.

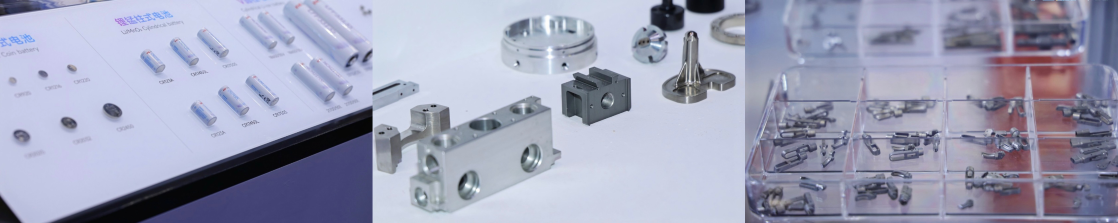

The group of exhibitors encompasses the full spectrum of the industry. ITES China brings together a focused assembly of enterprises, including dedicated optical sorting system manufacturers and the specialized suppliers that support them. This includes providers of the core vision inspection equipment, camera components, vision software platforms, code readers, lenses, and all related components necessary for building a sorting solution. This convergence enables a comprehensive evaluation. Procurement teams and engineers can compare complete sorting systems, source critical subsystems for in-house integration, or find partners for custom projects. The exhibited technologies are directly applicable to the precision component production needs of major industries, including 3C/electronics, semiconductors, new energy lithium batteries, automotive parts, and machinery manufacturing.

Implementing an effective optical sorting system requires a detailed understanding of the components to be screened and the specific quality parameters that must be enforced. The technical proficiency of specialized optical sorting system manufacturers, supported by a robust component supply chain, offers viable pathways to automate this critical quality control step. For professionals tasked with improving production line yield and reliability, the Machine Vision Applications and Inspection Equipment section at ITES China presents a definitive opportunity for evaluation. We provide this platform to bridge the gap between technical specification and operational reality, offering a direct line to the technologies and expertise that make high-speed precision sorting a practical manufacturing asset.