Industrial RFID, Barcode, and 2D Code Reading Technologies: A Comparison Guide

【Introduction】 Industrial RFID, Barcode, and 2D Code Reading Technologies: A Comparison Guide

Automatic identification forms a critical data layer in manufacturing and logistics, enabling traceability, inventory control, and process automation. Three prevalent technologies—RFID, barcode, and 2D code reading—each serve this purpose through different technical avenues. Selecting between them requires an analysis of data density, reading range, environmental factors, and unit cost. At ITES China, we note that a clear functional comparison of these systems is a prerequisite for effective implementation. This guide outlines the operating principles of each technology, examines the production ecosystem supporting them, and identifies a venue for practical evaluation alongside related automation solutions.

.png)

Technical Mechanisms and Application Parameters

RFID (Radio-Frequency Identification) uses electromagnetic fields to read data stored on tags without direct line-of-sight. A reader emits a radio wave that powers a passive tag or communicates with an active one, retrieving a unique identifier. This method allows for batch reading of multiple tags and operation in dirty or obscured conditions. Conversely, traditional linear barcode and 2d code reading are optical technologies. Linear barcodes encode data in the varying widths of parallel lines, scanned by a laser or imager. 2d code reading, involving formats like QR codes or Data Matrix, captures information stored in both dimensions of a matrix, offering higher data capacity and better damage tolerance in a smaller area. While RFID excels in dynamic range and automation, optical barcode reading solutions often present a lower entry cost for straightforward identification tasks.

Supplier Landscape and Integrated Product Availability

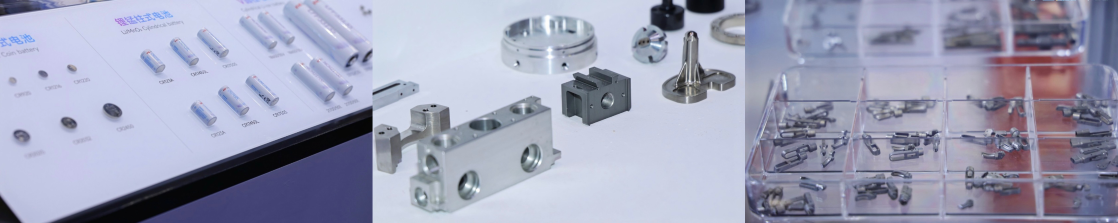

The global adoption of these technologies is supported by a mature and competitive manufacturing base. Companies specializing in barcode reading solutions offer a vast array of hardware, from handheld scanners and fixed mount readers to complex verification systems for print quality assessment. Similarly, suppliers focused on 2d code reading provide high-resolution imagers capable of decoding damaged or poorly printed marks on various surfaces. The supply chain advantage lies in the integration of these optical reading engines into broader systems—such as handheld computers, robotic guidance cells, or fully automated sorting lines—often facilitated by the proximity of component manufacturers. This ecosystem allows for the configuration of tailored barcode reading solutions that address specific challenges like high-speed conveyor reading or direct part marking (DPM) on metal.

A Dedicated Platform for Identification Technology at ITES China

Implementing an identification system extends beyond selecting a reader; it involves integrating sensors, software, and material handling. The industrial automation sectors at ITES China provide a focused environment to assess these technologies in context. This gathering moves the selection process from datasheets to operational demonstrations. The exhibition highlights concentrate on smart factory integration. Visitors can observe how RFID gates, fixed-mount 2d code reading cameras, and mobile barcode reading solutions are networked with warehouse management systems (WMS) and manufacturing execution systems (MES) to create a seamless data flow from component receipt to shipped product.

The exhibitors represent the full spectrum of the identification technology field. ITES China assembles a concentrated group of enterprises, including manufacturers of RFID tags and readers, companies providing advanced barcode reading solutions, and specialists in high-performance 2d code reading cameras. Alongside them are integrators who combine these readers with robotics, conveyors, and software platforms to create turnkey solutions. This collective presence allows for comparative analysis. Professionals can evaluate the read rates and form factors of different readers, discuss application-specific challenges with engineers, and source complementary equipment like label printers, verification stations, and encoding software. The demonstrated applications show direct relevance to industries requiring stringent traceability, such as automotive, electronics, pharmaceuticals, and logistics.

Determining the appropriate identification technology—RFID, barcode, or 2D code—depends on a clear assessment of data requirements, environmental conditions, and process integration needs. The extensive capabilities of suppliers in providing robust barcode reading solutions and sophisticated 2d code reading systems offer multiple pathways to reliable data capture. For teams responsible for implementing traceability or process automation, the focused exhibits at ITES China present a direct method for validation. We facilitate this technical evaluation, offering a platform where identification technologies can be examined not as isolated devices, but as functional components within a larger production system.