How Surface Treatment Technologies Enhance the Performance of Precision Components

【Introduction】 How Surface Treatment Technologies Enhance the Performance of Precision Components

In the world of high-stakes manufacturing, a precision component is more than its dimensional accuracy. Its true value is realized in operation—under load, in harsh environments, and over extended service life. This is where the science of surface treatment transforms a well-machined part into a high-performance engineered solution. For R&D engineers, procurement specialists, and quality managers, understanding this critical post-machining stage is essential for specifying components that deliver reliability and longevity.

.png)

Surface treatment encompasses a suite of processes applied to a part after precision component machining to alter its surface properties without changing its bulk geometry. Think of it as the final, defining layer of engineering that determines how the component interacts with the world. A perfectly machined gear can fail prematurely from wear; a meticulously crafted aerospace bracket can succumb to corrosion. Surface treatments are the calculated answer to these operational realities.

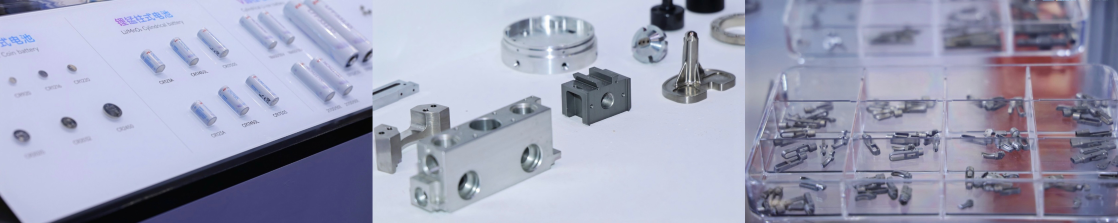

The goal is multifaceted: to enhance hardness and wear resistance, improve corrosion protection, reduce friction, modify electrical conductivity, or even provide aesthetic appeal. Processes range from established techniques like anodizing, plating, and heat treatment (e.g., carburizing, nitriding) to advanced methods like Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and laser cladding. Each technology offers a unique profile of benefits, and the selection is a critical design decision.

The Supplier Imperative: Integrating Machining with Surface Engineering

The most significant leap in component quality and efficiency occurs when surface treatment is not an afterthought but an integral part of the design and manufacturing dialogue. This is where the expertise of leading precision machining component suppliers within the ITES China ecosystem becomes a formidable advantage.

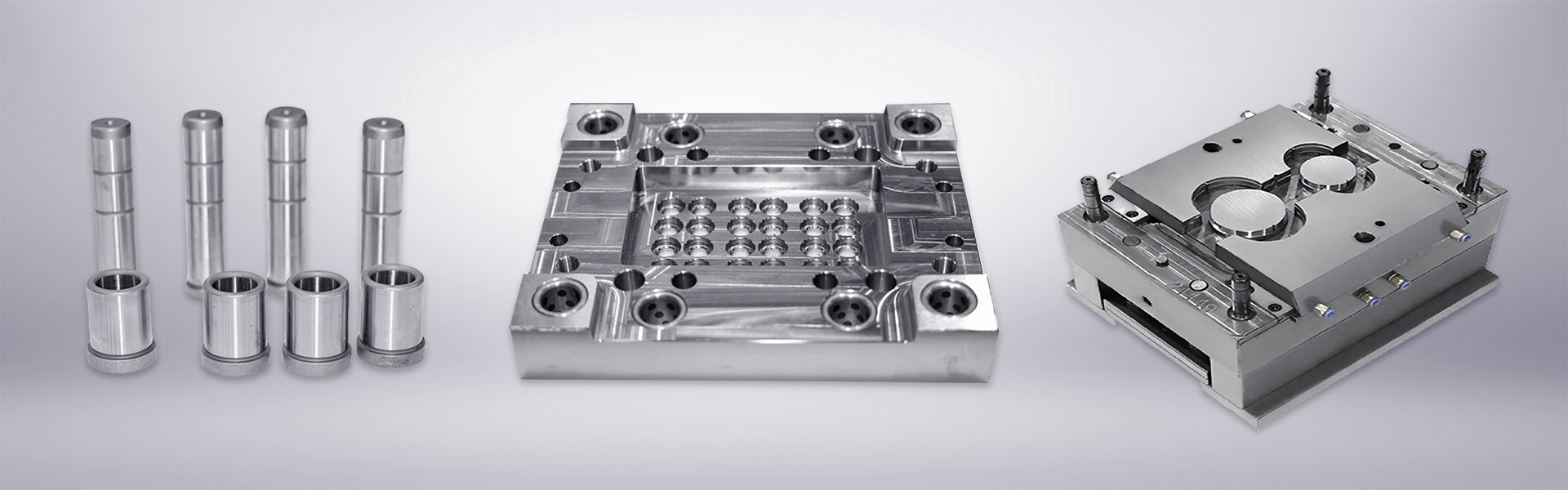

Progressive suppliers in this region have moved beyond offering machining and treatment as separate services. They provide vertically integrated solutions where their engineers consult on the optimal material and treatment combination from the prototype stage. This synergy is crucial. For instance, knowing that a part will undergo a specific coating allows the machinist to tailor the surface finish or tolerances to optimize adhesion and final performance. The concentrated industrial network in hubs like ITES China means a manufacturer can seamlessly coordinate between state-of-the-art CNC machining centers and specialized surface treatment facilities, often within a streamlined supply chain. This reduces lead times, ensures stringent process control, and guarantees that the final component meets exact performance criteria.

Witness the Surface of Innovation at ITES Shenzhen

While technical datasheets explain process capabilities, evaluating the results, comparing the latest technologies, and networking with integrated solution providers requires a hands-on approach. The ITES Shenzhen exhibition is the premier platform where the entire value chain of precision component machining and advanced finishing converges.

For professionals focused on elevating component performance, a visit to the exhibition is a targeted investment in sourcing and knowledge. The event is meticulously organized to showcase the journey from raw material to finished, treated part.

Exhibition Highlights & Scope: ITES Shenzhen features dedicated zones for Precision Processing and Surface Treatment Technology. Live demonstrations will show contrasting treated vs. untreated components undergoing stress tests, corrosion simulations, and wear analysis. Technical conferences will delve into trending topics such as eco-friendly plating alternatives, the rise of nano-coatings for medical devices, and digital process monitoring for coating uniformity.

Meet Integrated Exhibitors: The floor will host the industry’s foremost innovators. You will meet precision machining component suppliers who have in-house treatment divisions, as well as world-class specialist coating service providers. These are the experts who can discuss the feasibility of applying a wear-resistant PVD coating to a complex, thin-walled structure or the compatibility of a new anti-corrosion finish with your assembly’s lubricants. It is an unparalleled opportunity for technical collaboration.

Exhibits to Evaluate: This is your chance to inspect and compare. See micro-sections of treated components under microscopes to evaluate coating consistency. Feel the difference in surface hardness and lubricity. Examine components treated with the latest techniques like low-temperature CVD or high-velocity thermal spraying. From advanced pretreatment cleaning systems and precision masking solutions to the latest in automated coating lines and quality inspection equipment for treated surfaces, the full spectrum of enabling technology will be present.

In conclusion, specifying a precision component is incomplete without defining its surface characteristics. The integration of advanced precision component machining with engineered surface treatments is what creates parts that survive and thrive in demanding applications. By partnering with the sophisticated, integrated suppliers within the ITES China network and experiencing the frontier of these technologies at ITES Shenzhen, you can ensure your components are not just made to print, but engineered for exceptional performance. Discover the treatments that will define your product's future.