Plastic Mold Solutions: Injection, Extrusion, and Blow Molding Technologies

【Introduction】 Plastic Mold Solutions: Injection, Extrusion, and Blow Molding Technologies

Production across countless industries relies on shaped plastic. The creation of these components begins with a precise mold. For engineers and sourcing specialists, engaging with the field of China plastic mold making means understanding three primary processes: injection, extrusion, and blow molding. Each method serves distinct applications and end-product requirements. We will outline these core technologies and how the ecosystem surrounding plastic mold manufacturers in china supports global production needs.

Core Processes: Injection, Extrusion, and Blow Molding

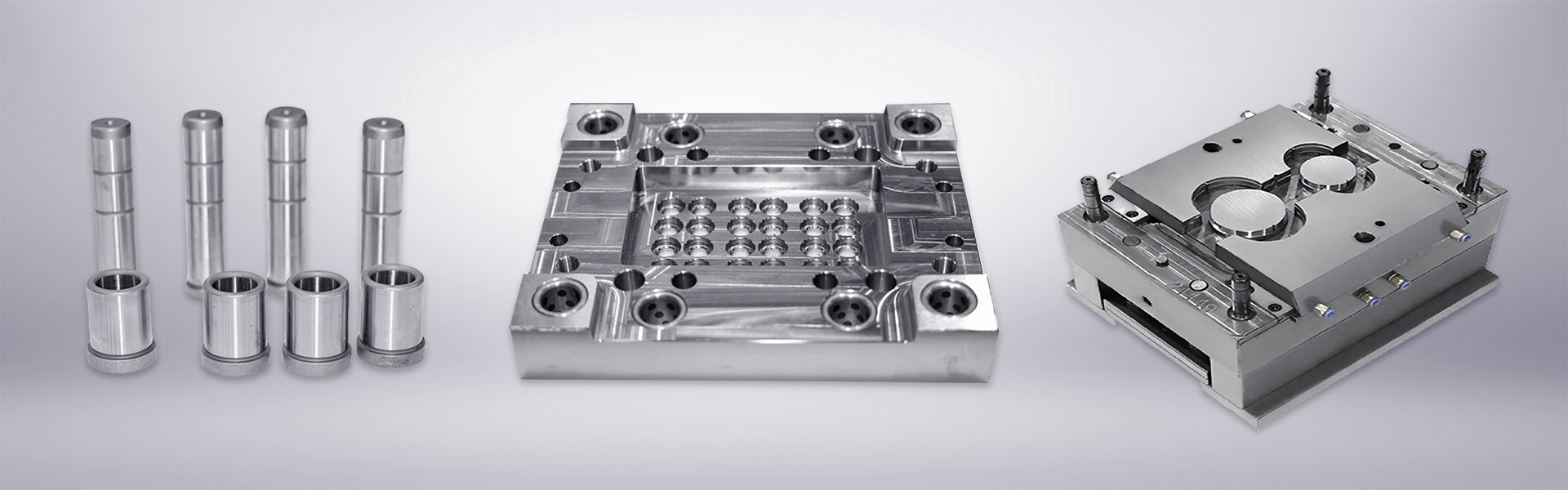

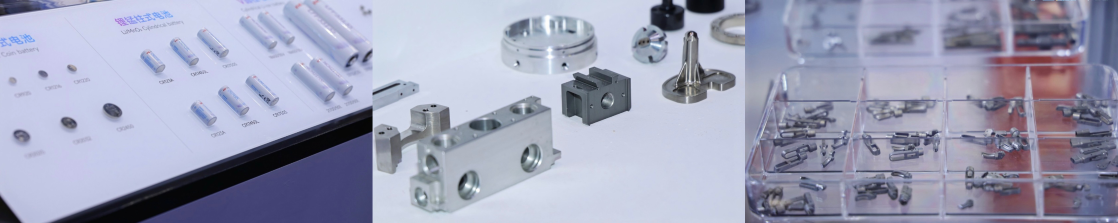

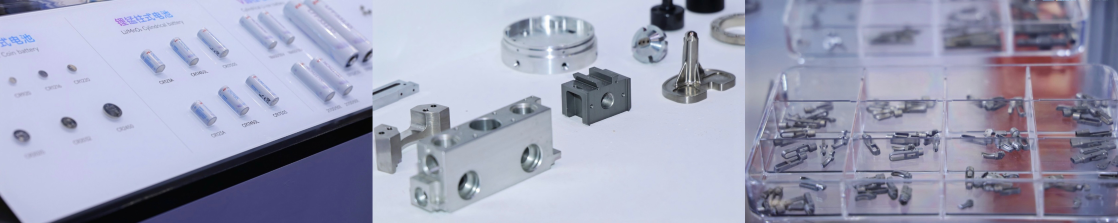

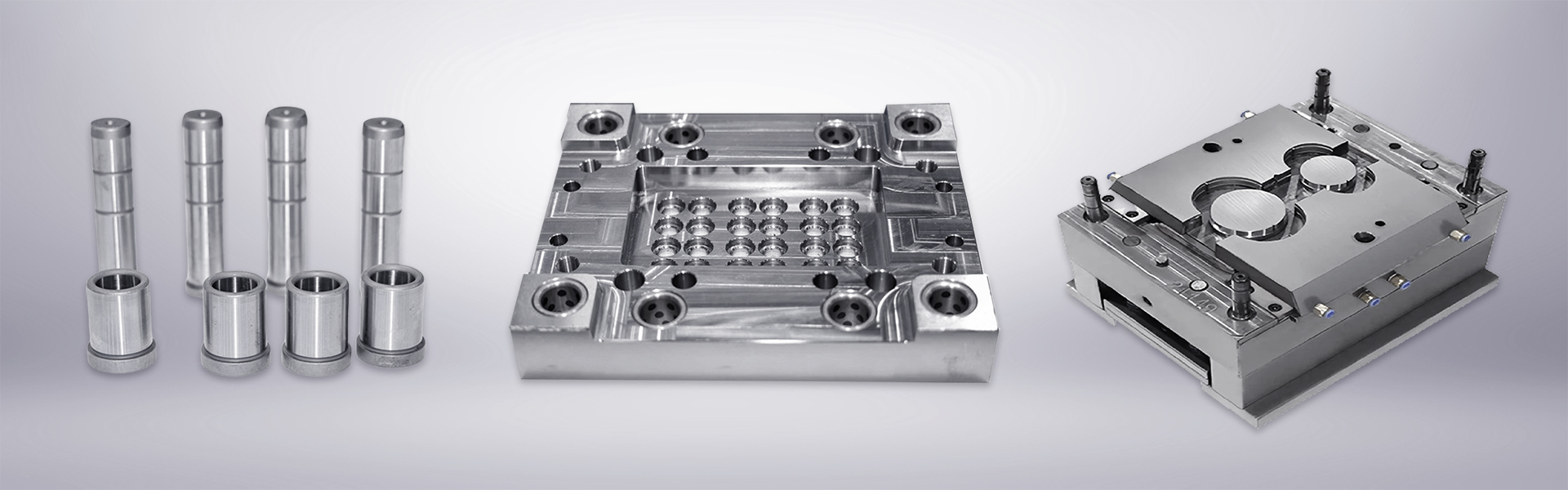

Plastic molding is not a single technique but a family of processes defined by the mold's function and the material's behavior. Injection molding involves heating plastic resin to a liquid state and forcibly injecting it into a closed, high-precision metal mold. This process is known for producing solid, complex parts with excellent dimensional accuracy and surface finish, suitable for everything from automotive interiors to medical device housings. Extrusion molding, in contrast, pushes melted plastic through a shaped die to create continuous, linear profiles like pipes, tubes, and sheet materials. The mold here is the die itself, determining the cross-section of the endless product. Blow molding is specialized for creating hollow objects. A parison (a tube of molten plastic) is placed into a two-part mold, and air is blown into it, expanding the material to match the mold's interior contours, commonly used for bottles, containers, and fluid tanks. The expertise in China plastic mold making spans the detailed tooling design required for each of these fundamentally different methods.

The Integrated Support Network for Mold Production

The capability of plastic mold manufacturers in china is amplified by a deeply integrated support network. This goes beyond machining the mold itself. It encompasses access to specialized steel and alloy providers, advanced surface treatment and heat treatment services, and readily available components like sliders, lifters, and standardized mold bases. This concentration of ancillary industries within manufacturing regions allows for rapid prototyping, iterative testing, and efficient maintenance. When a product design changes, the local supply chain can respond quickly with modifications. This ecosystem reduces logistical delays and provides mold makers with a comprehensive toolkit to solve complex design challenges, ultimately contributing to more reliable and durable tooling for end clients. This network effect is a structural aspect of sourcing from plastic mold manufacturers in china.

Direct Technical Evaluation at Industry Gatherings

While technical specifications are informative, assessing capability and innovation often requires direct engagement. This is where specialized exhibitions provide a critical interface. At ITES Shenzhen, the scope of exhibits directly covers the full spectrum of plastic molding technology, offering a venue to move from theory to practical evaluation.

The event serves as a concentrated showcase where professionals can meet a wide array of plastic mold manufacturers in china. Exhibits typically encompass the entire production chain. Visitors can inspect not only the finished molds but also the advanced CNC machining centers, EDM equipment, and polishing technologies used to create them. Furthermore, the exhibition highlights auxiliary equipment critical to the molding process, such as temperature controllers, drying hoppers, and robotic part removal systems. For those focused on China plastic mold making, ITES Shenzhen allows for side-by-side comparison of different suppliers' approaches to mold flow analysis, cooling channel design, and longevity engineering. These face-to-face discussions about material science, production cycles, and maintenance protocols are fundamental for making informed sourcing decisions and fostering technical partnerships.

The disciplines of injection, extrusion, and blow molding each address specific product geometries and performance needs. The sector supporting China plastic mold making is characterized by this technical breadth, supported by a dense network of material and component suppliers. Engaging with plastic mold manufacturers in china effectively involves a clear understanding of both the end application and the available tooling expertise. Platforms like ITES Shenzhen crystallize this broad market into a focused environment for technical exchange and capability assessment, providing a direct path to the partners and technologies that can turn a plastic component design into a manufacturable, high-quality reality. We facilitate this essential convergence at the event.