Custom Fasteners and Advanced Fastening Technologies: Bolts, Nuts, Screws, and More

【Introduction】 Custom Fasteners and Advanced Fastening Technologies: Bolts, Nuts, Screws, and More

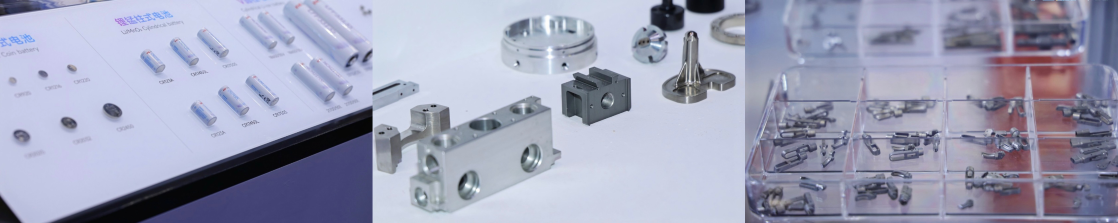

In complex machinery and equipment, the integrity of the entire assembly often depends on its smallest, most standardized parts. Fasteners—bolts, nuts, screws, rivets, and specialized pins—perform the critical function of joining components under stress, vibration, and load. When standard parts fall short, custom fastener manufacturing becomes essential. This process creates parts with specific materials, geometries, coatings, and performance characteristics to meet precise engineering requirements.

.jpg)

The Technical Scope of Custom Fastening Solutions

Custom fastener manufacturing addresses gaps left by catalog offerings. This can involve altering a standard thread pitch or shoulder length, manufacturing a part from a specific grade of stainless steel or titanium for corrosion resistance, or applying a unique plating for thermal or electrical properties. The technology extends beyond the part itself to include advanced driving and installation methods, such as precision torque control, thread-locking adhesives, and automated feeding systems for high-volume assembly. For engineers, the decision to pursue custom fasteners is driven by factors like weight reduction, space constraints, or the need to meet stringent industry standards for safety and durability. This technical domain requires close collaboration between the design team and the producer.

Capabilities of Specialized Producers in the Market

Producers focused on custom fastener manufacturers have developed capabilities that blend metallurgical knowledge with precision machining. Their value lies in navigating the complete journey from material selection and prototype testing to final production and certification. In regions like South China, a concentration of advanced manufacturing sectors—including automotive, lithium battery equipment, and specialized machinery—has cultivated a supplier base adept at responding to diverse and evolving demands. These custom fastener manufacturers often support clients by advising on design for manufacturability, suggesting material alternatives to optimize cost-performance ratios, and ensuring that the final product is reliable for its intended application environment.

The Supply Chain and Speed of Execution

A significant operational advantage within this sector is the condensed supply chain for inputs and secondary processing. Proximity to raw material distributors, heat treatment facilities, and surface coating specialists enables custom fastener manufacturers to accelerate prototyping and reduce lead times for production runs. This network efficiency is crucial for industries facing pressure to shorten development cycles. The ability to quickly iterate on a fastener design, test it, and move into controlled production can directly impact a larger project's timeline. This integrated ecosystem allows for a responsive approach to custom fastener manufacturing, turning specialized components from a potential bottleneck into a resolved element of the assembly process.

Engaging with the Fastening Ecosystem at ITES China

For procurement specialists and design engineers, specifying custom fasteners involves evaluating both the part and the producer's technical partnership capability. A focused industry exhibition provides an efficient forum for this assessment. The general mechanical components section at ITES China reflects the broad demand from South China's robust industrial base, where equipment manufacturing generates consistent need for precision parts, including fasteners.

At ITES China, professionals can connect directly with a range of custom fastener manufacturers. The exhibition facilitates a direct review of capabilities, from showcasing sample components across various materials and finishes to discussing application-specific challenges. Exhibitors often present their competencies in cold forging, machining, and secondary processing. Furthermore, the event allows visitors to explore complementary technologies, such as automated fastening tools, torque measurement systems, and inventory management solutions that integrate with just-in-time production. This consolidated view supports a comprehensive evaluation, helping to identify partners who can deliver not just a part, but a viable custom fastener manufacturing solution aligned with specific cost, quality, and logistical parameters.

Specifying bolts, nuts, screws, and other fasteners extends into a technical field where customization is frequently necessary. The producer landscape includes specialists equipped to handle complex requirements, supported by an efficient supply chain that enables rapid development. Direct engagement remains a effective method for evaluating these technical and operational capabilities. Platforms like ITES China assemble this specialized community, offering a practical environment to initiate the collaborations that ensure mechanical integrity and reliability in final products. We facilitate these connections to support advancements in manufacturing across numerous sectors.