Transmission and Coupling Components: Keys, Pins, Shafts, Couplings, and Clutches

【Introduction】 Transmission and Coupling Components: Keys, Pins, Shafts, Couplings, and Clutches

Machinery converts energy into motion, and at the center of this process are the physical elements that transfer and manage rotational force. This category includes fundamental transmission components like shafts, keys, and pins, which secure and drive elements, as well as coupling components such as couplings and clutches, which connect or control power between drives. For engineers managing maintenance or new builds, the specification of these parts directly influences operational reliability and efficiency. We will look at their functional importance and the supply environment that supports their procurement.

.jpg)

The Functional Role in Mechanical Systems

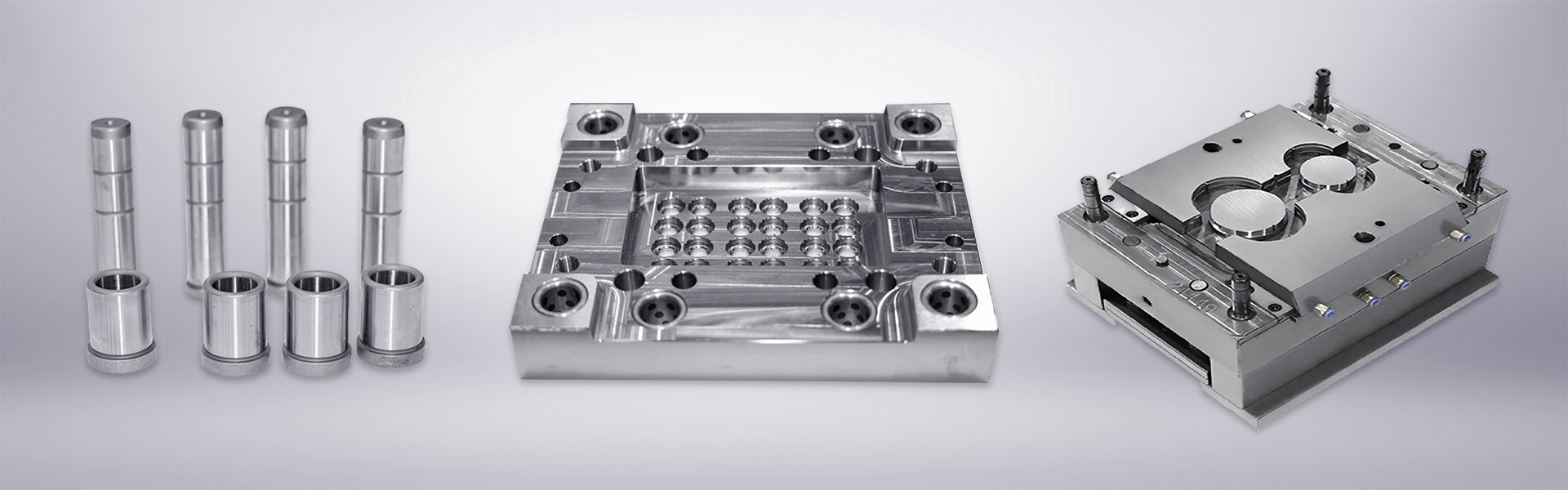

Every rotating system relies on a combination of these elements to operate. Transmission components form the essential backbone. A shaft provides the axis of rotation, while keys and pins positively lock gears, pulleys, and other elements to that shaft, preventing slippage under torque. Parallel to these, coupling components serve as critical junctions. Rigid or flexible couplings connect two shafts to transmit power while accommodating minor misalignments. Clutches, as another vital class of coupling components, provide controlled engagement and disengagement, allowing for starts, stops, and speed changes without halting the primary driver. The precise selection of these transmission components determines a system's load capacity, vibration characteristics, and service life.

Supplier Capabilities for Precision and Volume

The market for these parts includes specialists focused on high-volume standardization and those equipped for custom engineering. Producers of standard transmission components often operate with significant scale, offering reliability and cost-effectiveness for common specifications. For applications requiring special materials, tolerances, or designs—such as in high-speed packaging machinery or precision pharmaceutical equipment—the capability for customized manufacturing becomes essential. Suppliers adept in this area work with advanced alloys, perform specialized heat treatments, and apply particular surface finishes to meet unique stress, corrosion, or hygiene requirements. This dual-market structure allows buyers to source both catalog items and engineered solutions for coupling components from a concentrated industrial base.

Supply Chain Advantages for Equipment Manufacturers

A key reason for the strong presence of this sector in South China is the dense network of supporting industries. Equipment manufacturers here, spanning automotive, ceramic machinery, and lithium battery production, generate consistent demand for these universal parts. This demand supports a localized and responsive supply chain for transmission components. The proximity of raw material providers, forging specialists, machining workshops, and thermal processing services creates a streamlined pipeline from material to finished part. For an OEM, this integration can accelerate prototyping phases and reduce lead times for production volumes. The ability to rapidly source or develop a specific shaft or coupling can keep an entire equipment assembly project on schedule, making the ecosystem around coupling components a strategic operational asset.

Direct Sourcing and Evaluation at ITES Shenzhen

While technical data sheets are necessary, evaluating the quality and suitability of transmission components often benefits from physical inspection and direct discussion. Industry exhibitions dedicated to manufacturing technology provide this direct interface. The general mechanical components section at ITES Shenzhen reflects the substantial procurement demand from the region's diverse industrial base, making it a relevant venue for these sourcing activities.

At ITES Shenzhen, procurement teams and engineers can engage with a wide array of producers specializing in transmission components and coupling components. The exhibition allows for a hands-on assessment of the manufacturing quality for shafts, keys, and pins. It also offers the opportunity to compare the design and construction of various coupling components, from standard flexible jaw couplings to more specialized magnetic or hydraulic clutches. Discussions with exhibitor engineers can cover application scenarios, material specifications, and failure analysis, providing practical insights that inform procurement decisions. This environment consolidates a fragmented supplier landscape into a single platform for evaluation and connection.

The reliable transfer of mechanical power depends on the correct specification and quality of fundamental transmission components and coupling components. The supplier landscape offers both standardized and highly customized solutions, supported by an integrated regional supply chain that benefits equipment manufacturers. For professionals tasked with sourcing these parts, direct engagement with suppliers provides valuable clarity. Events like ITES Shenzhen facilitate this engagement by bringing the market's capabilities into focus, supporting the selection of components that ensure mechanical integrity and performance. We provide this platform to connect industrial demand with manufacturing supply.