How Medical Equipment Relies on Specialized Fabrication Methods

【Introduction】 How Medical Equipment Relies on Specialized Fabrication Methods

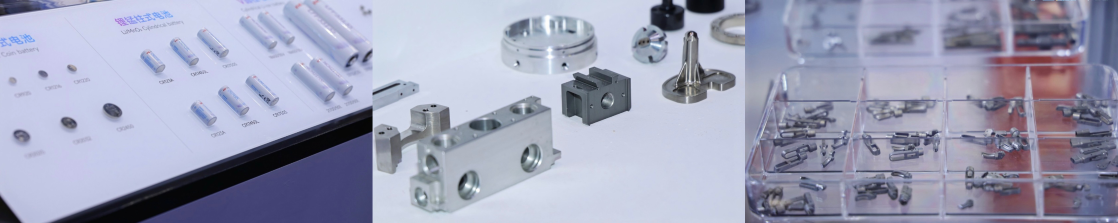

The development of medical equipment depends on transforming validated designs into physical devices that perform reliably. This translation from concept to component involves selecting manufacturing processes that align with a part's function, material, and regulatory context. Within precision medical component manufacturing, methods like CNC machining, sheet metal processing, and die casting are employed not as interchangeable options, but as specific solutions for distinct engineering challenges. We will outline the application of these processes and the environment that supports a high precision medical component manufacturer.

.png)

Application of CNC Machining for Intricate Device Parts

CNC machining is often selected for components where geometry, surface finish, and dimensional accuracy are critical. In medical devices, this applies to parts inside imaging systems, surgical handpieces, or connectors for fluid management. The process removes material from a solid block, guided by digital instructions, to produce features that might be impossible to form through other means. For a high precision medical component manufacturer, this demands control over every variable—tool path, cutting speed, coolant use—to achieve micron-level tolerances and requisite surface finishes on materials like titanium or medical-grade plastics. The method supports both prototyping, where designs are iterated, and production of components in volumes where investment in dedicated tooling is not justified.

Utilizing Sheet Metal for Enclosures and Supports

Sheet metal processing forms the outer shells and internal frames of many medical devices. This includes equipment housings, ventilator chassis, and mounting brackets for sensitive electronics. The process involves cutting, punching, and bending sheet stock into designed forms. For medical applications, the work extends beyond shaping to include ensuring edges are smooth, surfaces are prepared for cleaning or coating, and that the final assembly maintains electromagnetic compatibility or structural rigidity. A high precision medical component manufacturer working with sheet metal must integrate cleanliness into the fabrication process, often necessitating controlled environments to prevent contamination of parts destined for sterile settings.

Die Casting for High-Volume Functional Components

Die casting is a method suited for producing larger quantities of metal parts with consistent detail. In medical equipment, it can be used for components like pump bodies, gearbox housings, or handles where the process can integrate structural ribs and mounting points directly into the part. Molten metal is injected into a steel mold under pressure, creating a near-net-shape part. The advantage for precision medical component manufacturing lies in repeatability and efficient material use for certain part geometries. Success depends on sophisticated mold design to ensure proper filling and cooling, which minimizes porosity and maintains part strength. Secondary machining is frequently used on die-cast parts to achieve critical tolerances on specific interfaces.

The Technical Ecosystem for Advanced Medical Manufacturing

A high precision medical component manufacturer operates within a network of specialized suppliers. This ecosystem includes providers of certified raw materials, such as specific aluminum alloys or stainless steels, and partners offering advanced surface treatments like anodizing or passivation that enhance corrosion resistance and cleanability. This concentration of technical resources within industrial regions allows for tighter integration of the supply chain. It can reduce the time required to move from prototype to validated production, as material sourcing, primary processing, and finishing steps can be coordinated with greater efficiency. This integrated environment supports the exacting standards of precision medical component manufacturing.

Direct Engagement at a Focused Industry Platform

Evaluating these capabilities and identifying suitable partners benefits from direct interaction. The Core Components & Raw Materials Exhibition Zone at ITES Shenzhen is structured to facilitate these connections. This zone concentrates on the foundational elements of the medical device supply chain, presenting the technologies and services that enable advanced production.

For professionals involved in device development, ITES Shenzhen offers a direct route to the community of high precision medical component manufacturer companies. The exhibition provides a venue to assess their competencies across different processes. Visitors can examine sample components, discuss specific application challenges with engineering staff, and compare approaches to quality management. The zone also features exhibitors supplying the essential enabling elements: certified raw materials, advanced surface treatment technologies for biocompatibility and durability, and precision measurement equipment for quality assurance. Engaging with this concentrated gathering at ITES Shenzhen allows for technical discussions aimed at solving specific design and manufacturing bottlenecks, from material selection to final inspection.

Producing medical equipment involves matching design intentions with the appropriate fabrication methodology. CNC machining, sheet metal processing, and die casting each serve specific roles within precision medical component manufacturing. The availability of specialized manufacturers and a supportive technical ecosystem provides a foundation for device innovation. Connecting with this community directly offers practical pathways to overcome production challenges. The focused exhibition zone at ITES Shenzhen serves as a conduit for these essential engagements, linking medical device innovation with the manufacturing expertise required to realize it. We establish this platform to support progress in medical technology.