Choosing the Right Gripper: Mechanical, Vacuum, Magnetic, or Soft Gripping Solutions

【Introduction】 Choosing the Right Gripper: Mechanical, Vacuum, Magnetic, or Soft Gripping Solutions

Selecting an appropriate end effector is a fundamental technical decision in automation, directly influencing a system's flexibility, throughput, and reliability. The performance of a robotic cell often hinges on this critical interface. We observe that professionals frequently assess four primary categories: mechanical, vacuum, magnetic, and the increasingly prominent soft grippers. Each solution presents distinct advantages shaped by application-specific demands like part geometry, surface texture, and required handling force. For teams sourcing end effectors for robots, a clear understanding of these options forms the basis for effective procurement and system integration.

Core Gripper Technologies and Their Application Scope

Mechanical grippers, utilizing jaws or fingers, offer high precision and force for rigid, well-defined parts. Vacuum grippers, employing suction cups, excel in handling non-porous, flat or curved surfaces like panels or glass, enabling rapid pick-and-place operations. Magnetic grippers provide a robust solution for ferrous materials, often used in heavy stamping or sheet metal handling where other methods may struggle. Meanwhile, soft grippers, constructed from compliant materials, are engineered for fragile, irregular, or easily marred items, such as food products or electronic components. The choice among these end effectors for robots is seldom arbitrary; it requires a systematic analysis of the workpiece and the production environment.

The Landscape of End Effectors Suppliers and Regional Supply Chain Strengths

The global market for end effectors suppliers is diverse, with a significant concentration of manufacturing expertise and capacity located in Asia. ITES China operates within this ecosystem, connecting buyers with a broad network of specialists. Suppliers within this region have developed extensive capabilities, often supporting both high-volume production of standard components and the customization necessary for specialized applications. This supply chain strength allows for a considerable range of options in terms of cost, delivery lead times, and technical support. Engaging with these end effectors suppliers provides access to a depth of practical experience in solving real-world automation challenges across numerous industries.

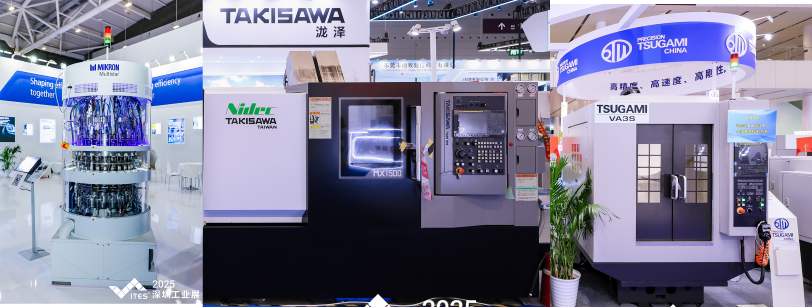

Direct Evaluation at the Industrial Manufacturing Trade Fair

Theoretical comparison has limits, which is why direct, hands-on evaluation remains irreplaceable. The dedicated End-Effectors & Electro-Hydraulic-Pneumatic Solutions Zone at ITES China is structured for this purpose. This zone brings together dozens of exhibitors presenting automated solutions for grasping, clamping, positioning, and tool quick-changes. Attendees can inspect a comprehensive array of products, from electric and pneumatic grippers to sophisticated multi-fingered dexterous hands and zero-point positioning systems. This concentration of technology transforms the event into a functional marketplace for end effectors suppliers and engineers to collaborate.

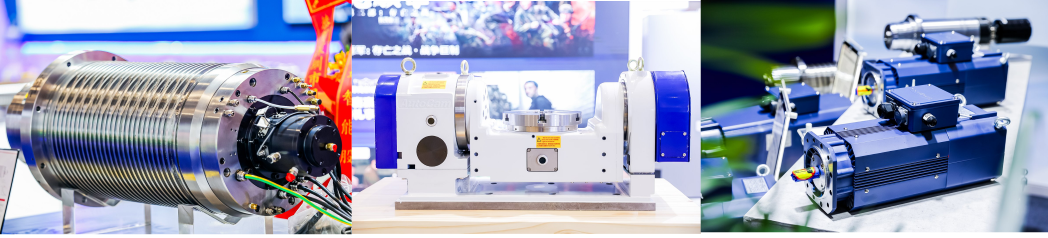

At our exhibition, the scope extends beyond the gripper itself to the entire system. Professionals can examine complementary electro-hydraulic-pneumatic devices—actuators, cylinders, valves, and sealing solutions—that enable the gripper to function. Seeing these components together facilitates a more holistic approach to cell design. The ITES China platform enables this integrated view, allowing visitors to assess not just a single component but the interoperability of gripping mechanisms, sensors, and fluid power systems. It is an environment designed for comparative analysis and technical discovery.

The decision for a gripping solution balances engineering specifications with practical supply chain considerations. Our industrial manufacturing trade fair acknowledges this duality by uniting technical education with commercial access. The forthcoming edition provides a direct channel to evaluate the physical properties and build quality of various grippers, from robust magnetic chucks to adaptive soft grippers. We facilitate these connections across our five sub-exhibition areas, supporting the industry’s move towards more precise and efficient component production and assembly. For teams engaged in specifying or upgrading automation, this direct engagement presents a tangible step toward optimizing their operational performance.