Key Components of Pneumatic Systems: Cylinders, Valves, Tubing, and Air Treatment Units

【Introduction】 Key Components of Pneumatic Systems: Cylinders, Valves, Tubing, and Air Treatment Units

Functioning as the muscle and nerves of countless automated processes, pneumatic systems provide reliable force and motion control. Their widespread use from factory assembly lines to specialized robotic tools hinges on the performance of four fundamental elements. We will examine the roles of cylinders, valves, tubing, and air treatment units, with particular attention to the integrated supply chain for end effectors for robots available within the region. This local manufacturing ecosystem supports the development and production of these core components, forming a robust base for automation solutions.

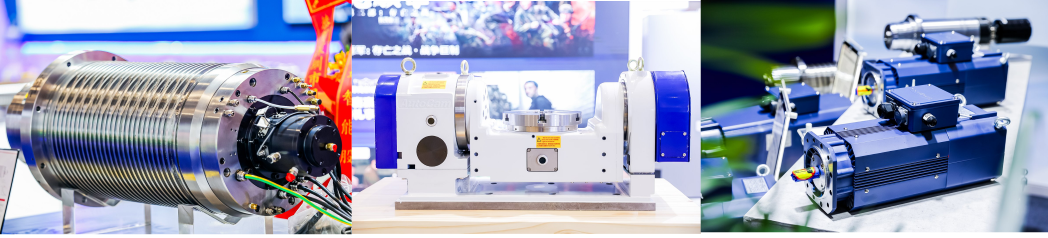

Cylinders and Valves: The Core Actuators and Control Points

The cylinder converts compressed air energy into linear mechanical motion, serving as the primary actuator. Valves, acting as the control system’s switches, precisely manage the direction, flow, and pressure of the air supplied to these actuators. The synergy between a correctly specified valve and a cylinder determines the speed, force, and repeatability of a motion sequence. For engineers designing an end effector in China, access to a diverse and cost-effective local portfolio of these components is crucial. A strong domestic manufacturing base for pneumatic cylinders and valves allows for rapid prototyping, simplified logistics, and responsive technical support, which accelerates the integration of automation into production cells.

Tubing and Air Treatment: The Vital Distribution and Conditioning Network

While often considered ancillary, tubing and air treatment units are critical for system integrity and longevity. Tubing forms the distribution network, conveying compressed air from the source to the point of use with minimal pressure drop and leakage. Meanwhile, air treatment units—comprising filters, regulators, and lubricators—prepare the compressed air. They remove contaminants, control pressure, and add lubrication to internal moving parts. Specifying the correct tubing diameter, material, and fittings, alongside properly scaled air preparation, prevents performance degradation. The concentrated supplier network accessible through platforms like ITES China makes sourcing compatible, high-quality ancillary components a more streamlined process for system integrators.

Integration and Sourcing at a Specialized Industrial Platform

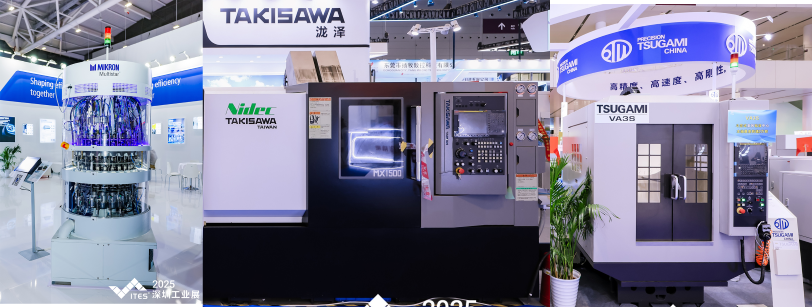

Selecting individual components is only part of the engineering challenge; ensuring their optimal integration within a complete system is key. This is where a comprehensive industrial exhibition provides distinct value. At ITES China, the dedicated End-Effectors & Electro-Hydraulic-Pneumatic Solutions Zone addresses this need directly. Dozens of exhibitors present a cohesive ecosystem of automation technology. Visitors can examine not just standalone pneumatic cylinders and valves, but see them configured within complete gripping, clamping, and positioning solutions. The zone showcases the direct application of these components in robot quick-changers, electric and pneumatic grippers, and sophisticated multi-fingered dexterous hands.

The exhibition scope provides a concentrated view of the entire fluid power and actuation landscape. Alongside core pneumatic devices, attendees can evaluate complementary technologies such as hydraulic actuators, torque sensors, and advanced sealing solutions. This environment allows for side-by-side comparison of components for end effectors for robots from various suppliers, facilitating informed procurement decisions. For any professional involved in specifying or integrating pneumatic systems and robotic tooling, ITES China serves as a functional marketplace. It connects the foundational technology of cylinders and valves with the advanced applications that define modern automated manufacturing, all within the context of a developed local supply chain for an end effector in China.