What Are CNC Spindles and How Do They Work?

【Introduction】 What Are CNC Spindles and How Do They Work?

At the heart of every computer numerical control machine, a critical component converts power into precision. This component is the CNC spindle, the rotating axis that holds and drives the cutting tool or workpiece. Its function seems straightforward, but the engineering inside dictates the machine's capability for speed, accuracy, and power. We will look at the operational principles of these units and consider the manufacturing ecosystem supporting a cnc spindle manufacturer within the regional supply network.

Core Function and Internal Mechanisms

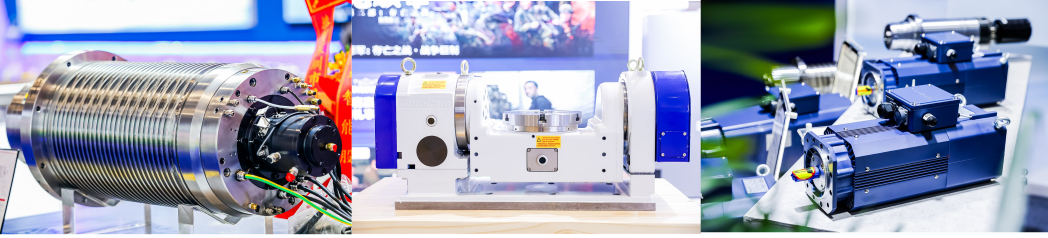

A China cnc spindle is fundamentally a high-precision motorized shaft. Its primary job is to impart rotational force to a cutting tool, such as an end mill or drill bit, with exceptional stability and minimal vibration. Inside, a spindle assembly typically integrates a motor (often electric, but sometimes powered by a belt or turbine), a precision bearing system to manage radial and axial loads, and a tool-holding mechanism like a collet or shrink-fit system. The rotation is controlled by the machine's computer, which dictates the spindle speed (RPM) with exact timing. The performance of this entire assembly directly influences the surface finish, tool life, and geometric accuracy of the machined part. For operations sourcing a China cnc spindle, understanding these internal specifications is the first step toward selecting a unit matched to specific material removal tasks.

Types and Application Considerations

Spindles are categorized by their power source, speed range, and cooling method. Common types include integral motor spindles, where the rotor is built directly onto the shaft for high rigidity, and belt-driven spindles, which offer flexibility in speed and torque. A key decision involves balancing speed and torque; high-speed spindles excel in fine finishing of alloys or machining composites, while high-torque spindles are necessary for heavy milling in steel or titanium. The growth of the local manufacturing sector has allowed a cnc spindle manufacturer to develop specialized product lines that address distinct industry needs, from high-volume production for the 3C electronics sector to robust, heavy-duty units for automotive component fabrication.

The Integrated Supply Chain for Precision Components

Selecting a spindle is not an isolated decision. Its performance is interdependent with other core functional components within the machine tool. The linear guides that carry the axis movement, the ball screws that translate rotary motion to linear motion, and the rotary tables that provide additional axes of rotation must all work in concert with the CNC spindle to achieve system-wide precision. A significant advantage for equipment builders and end-users in the region is the presence of a clustered, mature supply chain. This network provides coordinated access to these interrelated components—spindles, guides, screws, and tables—from multiple specialized suppliers. This concentration facilitates technical collaboration, simplifies logistics, and supports the integrated design of complete machining systems.

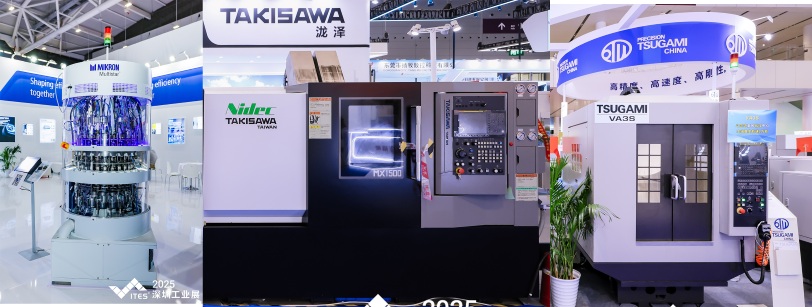

Direct Engagement at a Component-Focused Exhibition

Technical data sheets provide essential information, but evaluating the build quality, vibration characteristics, and thermal stability of a CNC spindle requires physical inspection. The Core Functional Components zone at ITES China exists to enable this direct engagement. This dedicated segment of the exhibition concentrates specifically on the high-precision elements that form the backbone of advanced machine tools. Here, engineers and procurement specialists can interact with multiple technical teams from different cnc spindle manufacturer companies. They can discuss specific requirements for power, speed, and interface protocols, and compare the engineering solutions offered for challenging applications in medical device or aerospace manufacturing.

The exhibition scope presents a complete picture of the precision ecosystem. Alongside various China cnc spindle exhibits, visitors to ITES China will find the complementary technologies that enable spindle performance. This includes high-accuracy rotary tables for multi-axis machining, automatic tool magazines that work in unison with the spindle for uninterrupted operation, and power heads that add functionality. The concurrent display of ball screws and linear guides allows professionals to source the complete mechanical drive and guidance system from the same platform. For any business involved in building, maintaining, or upgrading CNC equipment, visiting this zone at ITES China offers a consolidated view of the core technologies that define machining capability. It connects the theoretical operation of a CNC spindle with the practical realities of sourcing, integration, and application within a global manufacturing context.