Linear Guides for Smooth and Accurate Machine Movements

【Introduction】 Linear Guides for Smooth and Accurate Machine Movements

Precision in industrial machinery is frequently determined by the performance of its most fundamental components. Among these, the linear guide stands out as a critical element for ensuring smooth, accurate, and reliable motion in applications from machine tools to automated assembly systems. The selection of an appropriate linear guide directly influences a machine's positional accuracy, load capacity, long-term stability, and maintenance requirements. We see that engineers sourcing China linear guide components are tasked with balancing rigorous technical specifications against project economics and supply chain resilience, a process that requires both clear parameters and access to qualified suppliers.

Technical Foundations and Application Demands

A linear guide system functions by providing a constrained, low-friction path for linear motion. Its core performance is measured by parameters such as rigidity, precision grade, load rating, and operational lifespan. Different applications impose distinct demands; a high-speed gantry in a 3C electronics assembly line may prioritize low friction and high acceleration, while a heavy-duty machining center will require exceptional rigidity and moment load capacity. The design intricacies—from the recirculation of ball or roller elements to the sealing mechanisms that protect against contamination—are engineered to meet these specific challenges. Understanding these technical fundamentals is the first step in specifying the correct component for a system where precision is non-negotiable.

The Supplier Landscape and Manufacturing Ecosystem

The global market for linear guide manufacturers is robust, with a significant portion of manufacturing and innovation anchored in Asia. Sourcing a China linear guide offers access to a mature and stratified supply chain. This ecosystem includes large-scale producers capable of high-volume standardized output and specialized firms focused on custom or high-precision solutions. The advantage of this environment lies in its integrated supply network for materials and sub-components, which can contribute to competitive lead times and cost structures. For buyers, engaging with linear guide manufacturers within this region involves evaluating their technical documentation, quality certification processes, and proven ability to supply components that meet the stringent demands of sectors like automotive manufacturing and medical devices.

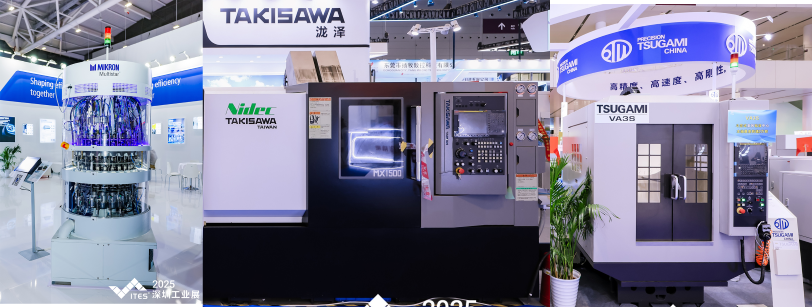

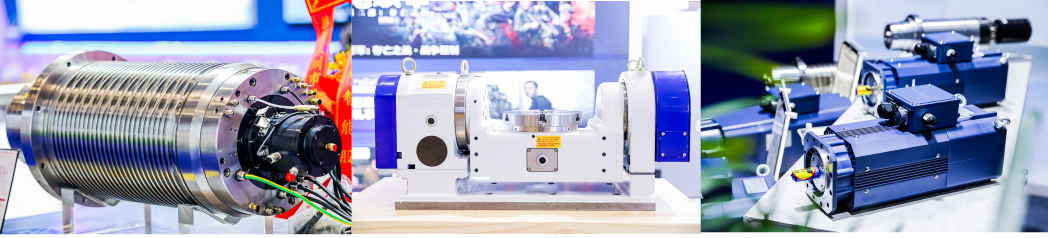

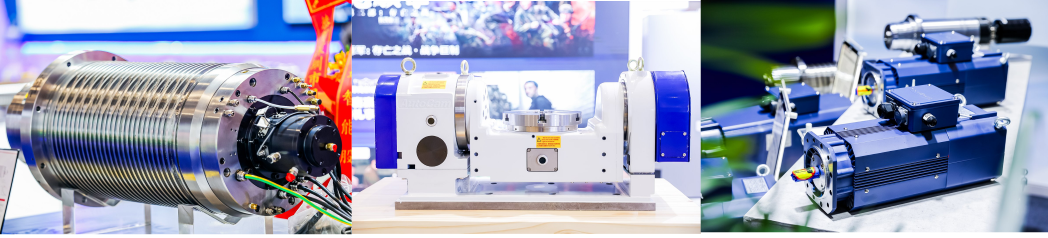

Direct Evaluation at the Core Components Exhibition Zone

While technical datasheets are essential, the tactile evaluation of build quality, smoothness of operation, and engineering support is irreplaceable. The Core Functional Components zone at ITES China is designed to facilitate this critical phase of the sourcing journey. This zone concentrates on the essential building blocks of high-end equipment, with linear guide systems featured prominently alongside complementary components like spindles, ball screws, and rotary tables. Visiting this dedicated section allows engineers to compare the physical attributes and craftsmanship of products from various linear guide manufacturers in a single, focused environment, transforming specification review into tangible assessment.

The exhibition scope at ITES China provides a holistic view of the precision motion ecosystem. It is not solely about the guide rail and block; it encompasses the interconnected technologies that form a complete system. Attendees can examine the interplay between a China linear guide, a high-precision ball screw for drive, and a rigid spindle for machining—all within the same exhibition zone. This context is vital for understanding compatibility and integration requirements. Discussions with technical representatives at the booths can address application-specific questions, from load calculations and mounting surfaces to lubrication intervals and environmental protection, offering insights that catalogs alone cannot provide.

Specifying linear motion components is a detailed process that links engineering design with supplier capability. The ITES China industrial manufacturing trade fair creates a direct channel for this essential work. By assembling a critical mass of core component specialists within one of our five defined sub-exhibition areas, we enable an efficient and thorough evaluation process. For professionals tasked with procuring components that define machine performance and longevity, this opportunity to engage with multiple linear guide manufacturers, assess product quality firsthand, and discuss integration challenges is a substantive step toward securing reliable and accurate motion solutions for their equipment.