Vibration Feeding Systems: Key Technologies for High-Speed, Stable Material Handling

【Introduction】 Vibration Feeding Systems: Key Technologies for High-Speed, Stable Material Handling

Vibration feeding has become an essential solution in modern industrial production, and at ITES China, we focus on presenting innovative systems that ensure reliable material transfer. High-speed China vibrating feeder systems are crucial for maintaining consistent workflows, especially when handling delicate or precision components. Our company emphasizes the integration of advanced vibration control technology, which allows materials to move smoothly and steadily, reducing the risk of blockages or inconsistencies. By leveraging insights from vibrating feeder manufacturers, we ensure that our solutions are aligned with current industrial demands while maintaining high operational stability.

Precision and Efficiency in Modern Feeding Systems

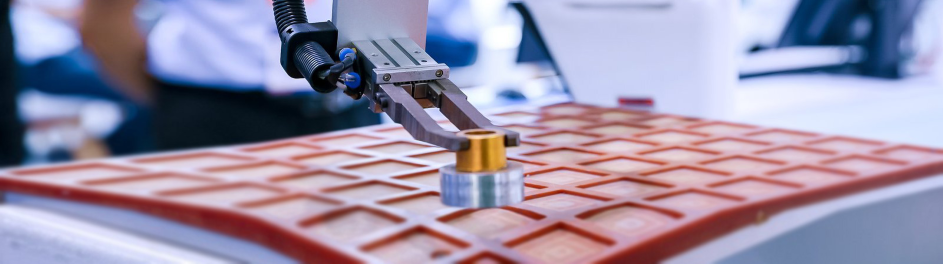

We recognize that high-precision manufacturing requires feeding systems capable of handling various materials without compromising accuracy. Our China vibrating feeder designs incorporate multi-axis vibration controllers, which provide uniform material flow even for small or irregularly shaped components. This approach not only optimizes throughput but also minimizes the potential for mechanical wear and tear. Collaborating closely with experienced vibrating feeder manufacturers, our company continuously refines these systems to match the dynamic needs of assembly automation, electronics, and semiconductor industries, ensuring materials arrive at the right place, in the right quantity, every time.

Supply Chain and Manufacturing Advantages

Choosing ITES China solutions means benefiting from robust supply chain support and reliable sourcing from established vibrating feeder manufacturers. By working with local and international suppliers, we streamline procurement, reduce lead times, and enhance production efficiency. Our company leverages strategic partnerships to maintain consistent quality, enabling businesses to focus on innovation and productivity. High-speed China vibrating feeder systems are integrated into flexible production lines, offering adaptability for small-batch, high-mix manufacturing environments, which is increasingly essential in today’s competitive industrial landscape. Moreover, we provide comprehensive after-sales support, real-time monitoring solutions, and customizable configurations to suit specific production needs. These systems are designed to improve material flow consistency, minimize operational downtime, and allow companies to scale production efficiently while maintaining high-quality standards across different industries and applications.

Showcasing Innovations at ITES China

At the upcoming ITES China exhibition, we will highlight the latest advancements in vibration feeding technologies, featuring exhibits from top vibrating feeder manufacturers. Visitors can experience demonstrations of high-speed China vibrating feeder systems, alongside other intelligent conveying and loading/unloading solutions. Exhibits will showcase automated handling for electronics, semiconductors, and precision components, emphasizing energy efficiency, operational stability, and integration with warehouse systems. Attendees will also have the opportunity to explore flexible loading solutions and network with industry experts, gaining insights into emerging trends and practical applications.

Industry Insights

Exploring vibration feeding technologies at ITES China reinforces the importance of precision, reliability, and efficiency in material handling. Our company remains committed to providing high-speed China vibrating feeder systems designed for stable and consistent operation, while leveraging the expertise of leading vibrating feeder manufacturers. By combining technical innovation with practical applications, we aim to support industrial partners in achieving higher throughput, reducing downtime, and enhancing production quality. The exhibition serves as a platform to witness these advancements firsthand, connect with professionals, and discover how intelligent feeding solutions can transform modern manufacturing processes.