Flexible Loading and Unloading Technologies for Unmanned Production Lines

【Introduction】 Flexible Loading and Unloading Technologies for Unmanned Production Lines

Unmanned production lines are becoming increasingly important in modern manufacturing, and at ITES Shenzhen, we are committed to showcasing how flexible loading and flexible unloading technologies can revolutionize factory operations. Our company recognizes that the ability to handle different products efficiently while maintaining accuracy is key to improving productivity. By integrating advanced robotic systems, intelligent conveyors, and automated feeding solutions, we ensure materials move smoothly across the production line, reducing human dependency and operational errors. These innovations are particularly valuable in high-mix, low-volume production environments where adaptability is essential, and both our ITES China and ITES Shenzhen platforms provide the latest demonstrations and practical applications of these intelligent systems for industry professionals.

Advancing Automated Handling Systems

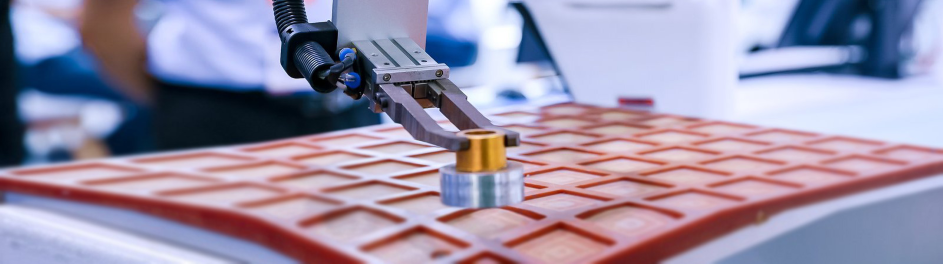

To achieve optimal performance, our flexible loading systems employ technologies such as vibratory feeders, tray stacking mechanisms, and adaptive robotic arms. These systems allow precise placement of components without manual intervention, enabling consistent quality and reducing cycle time. They can also adjust dynamically to different product sizes, shapes, and weights, providing true adaptability for mixed-production environments. Meanwhile, our flexible unloading solutions use 2D/3D vision guidance, SCARA robots, and adaptive gripping mechanisms to ensure finished products are accurately collected and sorted. These systems can detect orientation and alignment variations in real time, minimizing errors and preventing damage to delicate items. By implementing these systems, we help manufacturers handle delicate items such as electronic components, semiconductors, and automotive parts efficiently. The integration of flexible loading and flexible unloading not only improves line speed but also reduces material waste, lowers labor costs, and enhances overall production reliability, supporting a more sustainable and scalable manufacturing process.

Supply Chain Advantages and Chinese Manufacturing

At ITES China, we leverage the strengths of Chinese manufacturing to provide highly adaptable solutions. Our access to a robust local supply chain allows us to source high-quality components and quickly customize systems for specific production needs. This agility ensures that companies implementing flexible loading and flexible unloading technologies can respond faster to changing market demands. Working with experienced Chinese suppliers, we can integrate advanced robotics, control systems, and software seamlessly, helping clients enhance their operational efficiency. The combination of local supply flexibility and technical expertise makes our solutions both cost-effective and reliable.

Exhibition Highlights and Innovation Showcases

Our participation in ITES China provides a platform for visitors to explore the latest advancements in unmanned production line technology. The exhibition features live demonstrations of flexible loading and flexible unloading systems, including vibratory feeders, robotic workstations, and automated storage integrations. Attendees can witness how these technologies streamline processes in industries ranging from electronics to automotive assembly. Exhibitors from leading brands showcase practical solutions that address real-world manufacturing challenges. By experiencing these innovations firsthand, professionals can better understand the impact of flexible loading and flexible unloading on operational efficiency and product quality.

Strategic Insights and Conclusion

Conclusion: Embracing flexible loading and flexible unloading technologies is crucial for advancing unmanned production lines. At ITES China, we combine robotics expertise, automation solutions, and local manufacturing advantages to deliver systems that improve precision, adaptability, and reliability. Our exhibition highlights how these technologies can be applied across industries, offering manufacturers practical insights into intelligent production strategies. By integrating flexible loading and flexible unloading, companies can enhance productivity, reduce errors, and achieve smoother operations, ensuring they remain competitive in today’s fast-evolving manufacturing landscape.