Surface Treatment Solutions for Molds: PVD, CVD, Plating, and Thermal Spraying

【Introduction】 Surface Treatment Solutions for Molds: PVD, CVD, Plating, and Thermal Spraying

At ITES China, we recognize the critical role of mold surface treatment in achieving precision and durability. Whether in precision medical molding or precision aerospace molds, proper surface finishing ensures longer tool life, higher quality products, and consistent production performance. Technologies such as PVD, CVD, plating, and thermal spraying each offer unique advantages that meet the demands of modern manufacturing. These methods enhance wear resistance, reduce friction, and prevent corrosion, which is particularly vital for high-precision components. Beyond performance, these treatments also contribute to sustainable production by minimizing waste and reducing the need for frequent mold replacement, reflecting our commitment to both quality and environmental responsibility.

Understanding Surface Treatment Technologies

Our company applies various surface treatment techniques tailored to specific mold applications. PVD (Physical Vapor Deposition) creates a thin, hard coating that improves scratch resistance and thermal stability. Meanwhile, CVD (Chemical Vapor Deposition) provides uniform coatings even on complex geometries, ideal for molds used in precision aerospace molds. Plating, including electroplating and electroless plating, enhances corrosion protection and surface conductivity. Thermal spraying, on the other hand, deposits thick coatings to extend the life of molds subjected to high abrasion or thermal stress. We also focus on combining these techniques in hybrid applications when required, providing customized solutions that match the specific wear, chemical, or thermal conditions of each mold. By integrating these technologies, we ensure that our molds meet exacting standards across industries, including automotive, electronics, and medical devices, while optimizing production efficiency.

Advantages of Chinese Mold Suppliers

China’s manufacturing ecosystem provides significant advantages for our clients seeking precision medical molding solutions. By leveraging local suppliers, we benefit from a tightly connected supply chain, fast material availability, and competitive costs without compromising quality. At ITES China, our production integrates advanced CNC machining, 3D printing, and real-time quality control to maintain consistency. The regional clustering of mold manufacturers enables rapid prototyping and quick adjustments during product development. Furthermore, our company emphasizes continuous innovation and knowledge sharing across teams, ensuring that each project receives the latest technological insights. These factors make our surface treatment solutions both reliable and scalable, supporting diverse industry needs efficiently while maintaining high precision and repeatability.

Showcasing Our Innovations at ITES China

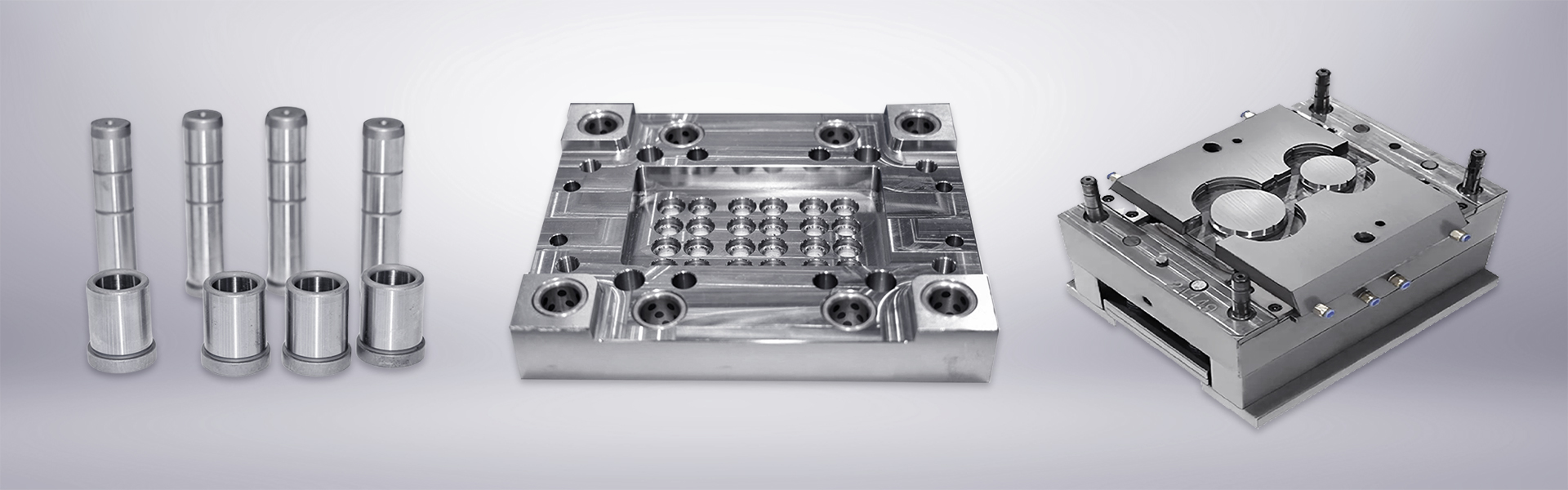

We are excited to present our latest developments in mold surface treatment at ITES China. This year’s exhibition features live demonstrations of PVD, CVD, plating, and thermal spraying processes, highlighting their effects on precision medical molding and precision aerospace molds. Visitors can explore our full range of mold components, including injection, stamping, and die-casting molds, as well as auxiliary equipment for design and maintenance. The event offers a unique platform for decision-makers, engineers, and procurement professionals to connect with exhibitors, evaluate cutting-edge technologies, and experience practical applications firsthand. Our team will provide detailed guidance on material selection, coating methods, and maintenance strategies. Additionally, the exhibition will showcase collaborations with other suppliers and innovative workflow solutions, giving attendees a comprehensive view of the mold manufacturing ecosystem in China.

Conclusion: Enhancing Mold Performance and Industry Collaboration

By combining advanced surface treatment technologies with the efficiency of China’s mold manufacturing network, we deliver solutions that improve performance, longevity, and product quality. Attending ITES China allows us to share insights on precision medical molding and precision aerospace molds, demonstrate our capabilities, and foster collaboration across industries. We invite professionals to engage with us at the exhibition to discover how these technologies can optimize their production processes, reduce maintenance costs, and support innovation in precision manufacturing. Our participation also underscores our commitment to providing transparent and practical solutions that meet the evolving needs of our clients.