Industry Applications of Precision Molds: Medical & Aerospace

【Introduction】 Industry Applications of Precision Molds: Medical & Aerospace

We at ITES China have seen firsthand how the demand for precision medical molding and precision aerospace molds continues to grow as manufacturers push the boundaries of quality, reliability, and performance in critical sectors. From surgical devices that save lives to complex aerospace components that must endure extreme conditions, precision molds play an indispensable role in shaping products that define modern industry. In Shenzhen and across the wider Guangdong-Hong Kong region, the deep integration of mold design, machining, and supply chain responsiveness has established a competitive environment for upstream component development and delivery. ITES Shenzhen’s location in this manufacturing powerhouse amplifies access to capable suppliers and advanced facilities, making it a focal point for innovators, engineers, and procurement professionals looking for precision mold solutions.

Precision Mold Fundamentals and Their Industry Impact

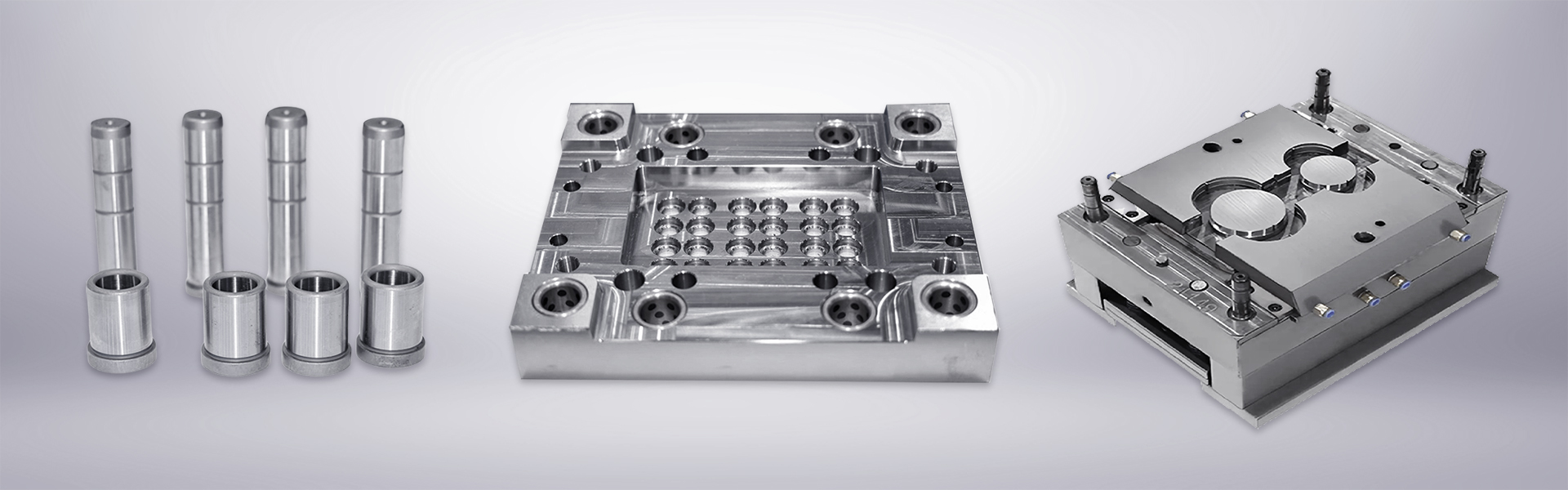

When we talk about precision medical molding, we’re referring to tooling solutions that deliver extremely tight tolerances and consistent repeatability for products such as implantable devices, diagnostic housings, and surgical instruments. These applications demand not just dimensional accuracy, but also surface finish quality and material compatibility — all critical for patient safety and regulatory compliance. Similarly, precision aerospace molds support components used in aircraft structural assemblies, engine systems, and other mission-critical parts where performance margins are narrow and failure is not an option. Across both medical and aerospace sectors, mold production must integrate advanced CAD/CAM design, high-performance machining, and rigorous inspection processes to achieve these outcomes. The manufacturing ecosystem showcased at ITES Shenzhen reflects these demands, with Precision Molds & Dies exhibitions covering everything from injection molds and stamping dies to digital design platforms and automation technologies.

China’s Precision Mold Supply Chain and Exhibition Insights

As part of the Chinese manufacturing landscape — including the ecosystem surrounding ITES China events — the Pearl River Delta region is recognized for its dense network of mold makers and precision machining specialists. This cluster allows buyers to engage with suppliers that have deep experience across industries and are capable of customizing solutions for niche requirements. During ITES Shenzhen, the Precision Molds & Dies section brings these capabilities into sharp focus by featuring tooling innovations, mold components, and digital solutions that help reduce lead times and improve production efficiency. Moreover, the exhibition’s broader context — spanning robotics, automation, and precision component machining — enables companies to explore comprehensive production strategies that go beyond just molds to end-to-end manufacturing workflows.

Exhibition Highlights and What We Offer at ITES Shenzhen

One of the standout features of ITES Shenzhen is the diversity of professionals and technologies brought together in one venue. Attendees from around the world — including production engineers, quality assurance specialists, and supply chain managers — come to explore innovations in precision manufacturing technology. The mold segment showcases tooling for everything from plastic injection molds to complex die-casting and forging solutions, addressing the diverse needs of medical and aerospace sectors alike. In addition to exhibits, the event includes forums and networking opportunities that help companies understand industry trends and forge valuable partnerships. As we prepare for the next edition, we remain committed to helping visitors connect with mold-making expertise and discover how precision tooling supports advancements in health care and aerospace engineering.

The Role of Precision Molds Across Sectors

Conclusion — In reflecting on precision medical molding, precision aerospace molds, and the broader context of modern manufacturing, it’s clear that high-precision tooling serves as a backbone for product excellence. At ITES China, and specifically within the scope of ITES Shenzhen exhibitions, we continue to witness how precision molds enable manufacturers to meet stringent performance requirements and accelerate innovation. Whether for medical devices that improve patient outcomes or aerospace components that withstand demanding environments, the integration of advanced mold design and execution remains pivotal. By participating in events like ITES Shenzhen, professionals gain not just exposure to leading-edge tooling technologies, but also insights into how precision molds integrate with intelligent manufacturing strategies that define tomorrow’s competitive advantage.