Surface Treatment Technologies for Medical Device Durability and Biocompatibility

【Introduction】 Surface Treatment Technologies for Medical Device Durability and Biocompatibility

Medical devices function in complex environments where durability and biocompatibility are essential for long-term performance. At ITES China, we understand that surface properties directly influence device reliability, corrosion resistance, wear behavior, and, critically, how a device interacts with human tissues. Advanced surface treatment technologies have become a cornerstone in precision device fabrication to ensure that components withstand sterilization cycles and bodily fluids without compromising patient safety. In this article, we explore key technologies and how they integrate with modern manufacturing practices.

Importance of Surface Treatments in Medical Devices

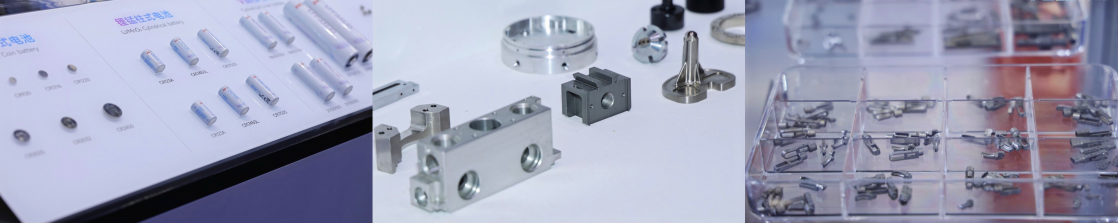

Surface treatment plays a crucial role in creating reliable medical products. When implants, surgical tools, and diagnostic instrument components are exposed to biological environments, untreated surfaces may lead to corrosion or adverse tissue reactions. Techniques such as passivation, electropolishing, coating, and plasma treatments create controlled surface chemistry and topology that enhance biocompatibility. These treatments also reduce friction and improve cleanability, which is critical for devices used in repetitive or long-term applications.

As a high- precision medical component manufacturer, we have seen that medical components with optimized surfaces experience fewer failures, longer life cycles, and better integration with human tissue. For example, electropolishing not only smooths micro roughness on stainless steel but also removes impurities that may compromise sterilization. Similarly, biocompatible coatings — including Parylene and titanium nitride — act as barriers that protect both the device and patient cells. These surface enhancements align closely with regulatory expectations while enabling superior clinical outcomes.

Surface Technologies and Medical Manufacturing Synergy

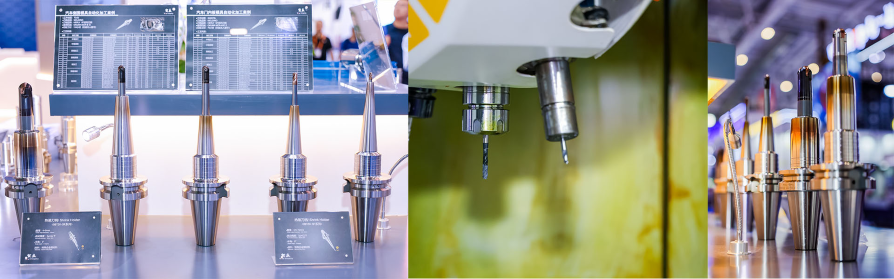

In modern medical manufacturing, surface treatments must be tightly integrated into component production workflows to maintain consistency and quality. At ITES Shenzhen, our approach incorporates surface technologies early in the manufacturing process to reduce rework and ensure seamless transitions between fabrication, inspection, and final assembly. This holistic coordination is especially important for complex geometries and micro features found in minimally invasive surgical tools and implantable devices.

We frequently leverage advanced characterization tools to verify surface quality — including profilometry and chemical analysis — which help us validate that coatings are uniform and corrosion resistance meets specifications. Treatments such as anodization can improve oxide layer stability on titanium alloys commonly used in orthopedic and dental implants. Additionally, plasma nitriding can significantly enhance surface hardness for cutting tools and instrumentation without compromising core strength. Each surface process we use is selected based on material compatibility, required durability, and patient safety considerations.

Driving Quality Through Supply Chain and Innovation

China’s manufacturing ecosystem offers robust infrastructure for medical surface treatments that support global supply chains. As part of ITES China, we engage with partners who specialize in advanced surface technologies while maintaining strict quality systems. This collaboration allows us to deliver comprehensive solutions that align with stringent medical standards and varying clinical requirements. Our role as a precision medical component manufacturing partner emphasizes both engineering expertise and reliable supply chain execution, which supports OEMs worldwide.

We will be presenting surface treatment innovations at upcoming industry events, highlighting how our integrated surface workflows can optimize throughput and device performance. Visitors to our booth will see live demonstrations of coating technologies, material case studies, and detailed discussions about how surface enhancements improve biocompatibility and longevity. These exhibition highlights are ideal for engineers, quality leaders, and procurement specialists seeking proven technical solutions.

Conclusion: Surface Excellence for Medical Device Success

In this Conclusion section, we reaffirm that surface treatment technologies are fundamental to medical device durability and biocompatibility. At ITES China, we focus not only on precision fabrication but also on how surface enhancements contribute to safer, longer-lasting medical products. Our experience as a high precision medical component manufacturer and collaboration with ITES Shenzhen partners ensures performance-driven solutions that support the needs of today’s complex medical supply chains. By integrating advanced surface processes with holistic manufacturing strategies and showcasing these at industry exhibitions, we continue to advance medical device quality with practical, science-based approaches.