Materials Used in Medical Device Manufacturing: Metals, Plastics, Polymers, and Ceramics

【Introduction】 Materials Used in Medical Device Manufacturing: Metals, Plastics, Polymers, and Ceramics

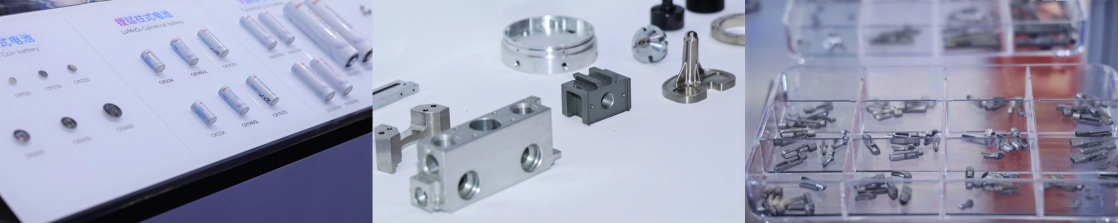

Medical device functionality and safety start with the choice of materials. At ITES China, we recognize that selecting appropriate materials is essential to ensure performance, durability, and compatibility with the human body. Today’s medical devices span a broad range of applications, from surgical instruments to implantable components, and material selection directly influences how these devices interact with biological systems. In this article, we explore metals, plastics, polymers, and ceramics commonly used in medical devices, connecting material science with precision medical component manufacturing practices. Through this exploration, we also share how our China-based supply chain supports innovation, including updates about our participation in relevant industry exhibitions.

Understanding Medical Device Materials

Material properties define how a medical device performs in its intended environment. Metals such as stainless steel, titanium alloys, and cobalt chromium are often chosen for load-bearing implants and instruments because of their mechanical strength and corrosion resistance. Plastics and medical-grade polymers like polyethylene, polyether ether ketone (PEEK), and silicone offer design flexibility, low weight, and chemical stability, making them suitable for disposable devices and components that require precision features. Additionally, ceramics such as alumina and zirconia are valued for wear resistance and biocompatibility in joint replacements and dental applications.

As a high precision medical component manufacturer, we work closely with design engineers to match material properties with functional requirements. Metals may undergo surface treatments to improve wear resistance, while polymers are selected for specific interactions with sterilization processes. Ceramics provide excellent hardness but must be handled carefully during fabrication to avoid microcracks. This focus on materials ensures that components produced through precision medical component manufacturing deliver consistent performance in end-use scenarios. When combining distinct material types within a single device, compatibility and processing methods become central to design decisions.

China Supply Chain and Product Integration

China’s manufacturing ecosystem offers a broad base of material expertise and production capacity that supports diverse medical device requirements. At ITES Shenzhen, we leverage these strengths to integrate material selection with machining, molding, and finishing processes tailored for medical applications. Whether fabricating complex metal parts or precision polymer components, our coordination across suppliers, material specialists, and quality systems enables us to maintain consistency throughout production cycles.

Exhibition Highlights and Industry Engagement

Engaging with the broader medical manufacturing community is essential for staying informed about material trends and technology advances. We will be participating in upcoming industry exhibitions where material science will be a featured topic. At these events, visitors can explore demonstration booths that showcase material applications in medical devices, including live discussions about metals, plastics, polymers, and ceramics. Exhibitors will present case studies that connect material choices with performance outcomes, illustrating how thoughtful selection enhances device reliability and patient outcomes.

Event highlights will include presentations from material experts, panel sessions on manufacturing challenges, and displays from suppliers offering novel material solutions. Our team from ITES Shenzhen will be available to discuss how precision medical component manufacturing strategies integrate material insights with fabrication workflows. Attendees will have opportunities to see components firsthand, compare material behaviors, and understand how they align with specific clinical needs. These interactions help bridge academic research with practical production considerations.

Conclusion: Aligning Materials with Medical Performance

Conclusion — Material selection remains a foundational aspect of medical device engineering, influencing performance, safety, and manufacturability. Throughout this discussion, we have outlined how metals, plastics, polymers, and ceramics contribute to diverse medical applications and how ITES China links material expertise with high precision medical component manufacturer capabilities. Our work at ITES Shenzhen reflects a commitment to integrating material science into reliable manufacturing practices and supply chain execution. By participating in industry exhibitions and engaging with stakeholders, we continue to support material-driven innovation that aligns with the evolving needs of medical device development.