Saw Blade: High-Performance Cutting for Various Materials

【Introduction】 Saw Blade: High-Performance Cutting for Various Materials

Every manufacturing process begins with a fundamental step: shaping the raw material. Within this initial phase, the cutting tool applied sets the stage for all subsequent operations, influencing efficiency, cost, and final product quality. As organizers of a major industrial technology platform, we recognize saw blade as a critical category within this foundational group. The selection of appropriate blade from competent industrial saw blade manufacturers directly affects productivity in sectors ranging from metal fabrication to woodworking and composite material processing.

Specialization in Blade Design for Material-Specific Challenges

The concept of a universal saw blade does not align with the demands of modern high-performance cutting. Different materials present unique challenges—metal creates heat and demands toughness, wood requires sharpness to avoid tear-out, and composites can be abrasive, wearing down cutting edges rapidly. Therefore, industrial saw blade manufacturers dedicate significant engineering to variables like tooth geometry, gullet design, and substrate material. A blade optimized for aluminum extrusion, with a specific hook angle and coating, will perform poorly on stainless steel or laminated wood. The most effective industrial saw blades manufacturers provide not just a product but a solution based on the workpiece material, desired cut quality, and production volume. This specialization is crucial for achieving clean cuts, extended tool life, and reduced cycle times.

Evaluating Manufacturer Capabilities and Integrated Supply

Choosing a supplier extends beyond selecting a blade from a catalog. It involves assessing a manufacturer’s technical support, ability to deliver custom solutions, and consistency in quality control. A reliable industrial saw blades manufacturers partner understands the entire cutting system, including the machine tool's capabilities and the required ancillary equipment. This holistic view allows for recommendations that optimize the entire process, not just a single component. The advantage of engaging with established manufacturing ecosystems includes access to comprehensive technical knowledge, faster iteration on custom specifications, and logistical efficiency. For operations running continuous production lines, this partnership and supply chain reliability are as valuable as the physical product, ensuring minimal disruption and consistent output quality.

The Practical Value of Direct Inspection and Comparison

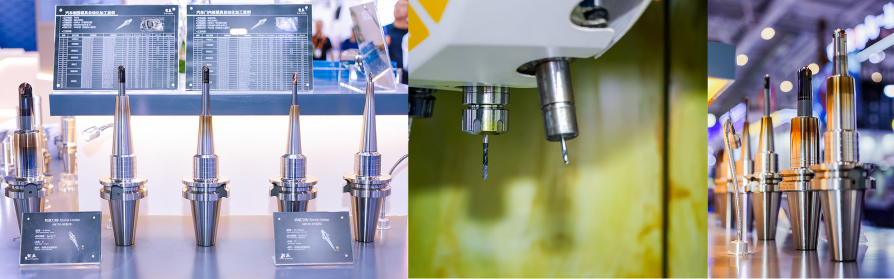

While technical specifications provide a necessary baseline, the performance of a saw blade is ultimately proven on the shop floor. Factors like vibration, noise, and real-world edge longevity are difficult to gauge from a datasheet alone. This gap between specification and application is where a professional exhibition delivers distinct value. At the Tools zone of ITES China, professionals encounter this critical product category firsthand. The exhibition brings together a wide range of industrial saw blade manufacturers and other cutting tool providers. Attendees can inspect blade construction, discuss specific material challenges with application engineers, and compare products designed for milling, turning, drilling, and sawing. This zone addresses practical industry needs like cost reduction, efficiency improvement, and machining difficult materials.

This focused environment allows for direct evaluation. A production manager can compare the tooth design of blade intended for the same material from different industrial saw blade manufacturers. A procurement specialist can discuss bulk order logistics and technical support protocols directly with supplier representatives. This interactive setting transforms the selection process from a remote, speculative activity into a tangible, informed assessment. It provides a consolidated view of available solutions, from standard carbide-tipped blade to specialized designs for unique alloys or advanced composites. Engaging with this concentrated assembly of technology and expertise at ITES China supports more confident procurement decisions and provides insights into the evolving capabilities of these essential industrial tools.