Special Forming Technologies for Complex Metal Parts: From Spinning to Cold Bending

【Introduction】 Special Forming Technologies for Complex Metal Parts: From Spinning to Cold Bending

Creating intricate, high-strength metal components often demands manufacturing solutions beyond standard stamping or machining. For parts with complex curvatures, seamless hollow forms, or specialized cross-sections, dedicated complex sheet metal forming processes become essential. Techniques like spinning and cold bending enable the production of these challenging geometries with material efficiency and structural integrity. We observe that engineers across sectors such as new energy and aerospace continuously evaluate these methods to solve specific design and production challenges. The journey from concept to finished part involves selecting not just a process, but a capable technology partner.

Defining Spinning and Cold Bending Processes

Spinning sheet metal forming is a versatile, incremental forming process. A rotating blank of metal is pressed against a mandrel by a tool, gradually shaping it into a symmetrical hollow part like a pressure vessel dome or a parabolic satellite dish. This method is recognized for its low tooling cost, suitability for prototypes and medium volumes, and its ability to maintain excellent material grain structure. Conversely, cold bending encompasses various techniques—like roll forming, press braking, and tube bending—that plastically deform sheet metal, tubes, or profiles at room temperature. It is fundamental for creating frames, enclosures, and structural components with high precision and repeatability. Both approaches address different facets of complex sheet metal forming, where the geometry of the final part dictates the appropriate technical path.

The Supplier Environment for Advanced Forming Equipment

The market for advanced forming machinery, including spinning sheet metal forming equipment, features a robust network of specialists. Sourcing these technologies often involves engaging with suppliers who possess deep application knowledge. The regional manufacturing ecosystem supports a comprehensive supply chain for components, controls, and after-sales service. This network allows equipment producers to offer competitive configurations, from manual machines for specialized workshops to fully automated CNC cells for high-volume production. For a buyer, this means access to a range of options, but also necessitates a careful evaluation of the manufacturer’s expertise in your specific industry, whether it's automotive manufacturing or medical device production.

A Platform for Direct Technology Assessment and Integration

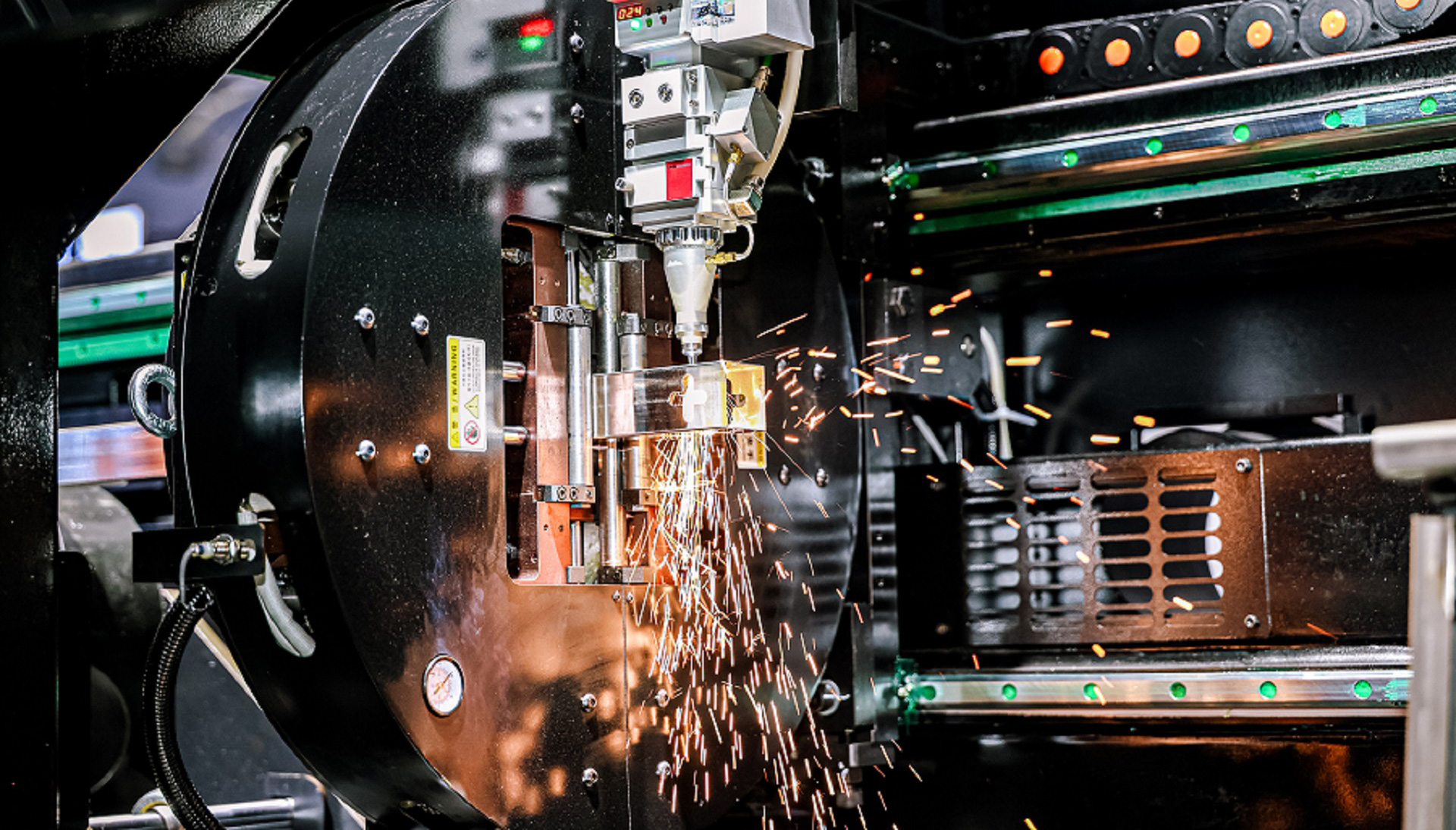

Evaluating such specialized equipment benefits greatly from physical demonstration. The Sheet Metal Processing Technologies & Automation Solutions zone at ITES Shenzhen serves as this critical evaluation platform. This dedicated area directly addresses industry pressures for cost reduction and efficiency improvement by bringing leading process technologies into a single location. Here, the terms complex sheet metal forming and spinning sheet metal forming transition from concepts to operational machinery. Visitors can witness live demonstrations of spinning machines alongside cold bending and curving machines, allowing for direct comparison of their capabilities, finished part quality, and operational workflows.

The scope of this zone at ITES Shenzhen provides a complete picture of the manufacturing chain. It is not only about the primary forming machine. Exhibits extend to the preceding and subsequent stages essential for a viable production cell. Professionals can examine high-power laser cutting machines that prepare blanks, advanced welding robots for assembly, and automated surface treatment lines for finishing. This integrated view is vital for planning an entire process flow. Discussions at the event can cover how a new spinning cell might interface with existing automation or what tooling options are available for a specific alloy.

Selecting a forming technology requires a balance of technical feasibility, equipment performance, and long-term supplier support. The ITES Shenzhen industrial manufacturing trade fair exists to make this complex decision more tangible. By organizing a focused zone within our larger five-area exhibition, we concentrate the relevant technologies and the experts who operate them. For engineers and production managers facing the challenge of manufacturing sophisticated metal parts, this environment offers a direct way to assess machinery, discuss application specifics with engineers, and identify solutions that meet stringent demands for precision and throughput. This hands-on engagement is a practical step toward implementing the advanced forming technologies that modern product designs require.