Industrial Applications of Humanoid Robots: From Assembly to Inspection and Logistics

【Introduction】 Industrial Applications of Humanoid Robots: From Assembly to Inspection and Logistics

We observe a significant shift within advanced manufacturing environments. The integration of humanoid robots, designed to operate in spaces built for human workers, is moving from concept to tangible pilot lines and specialized applications. For global manufacturers assessing this transition, China's ecosystem presents a notable convergence of agile development, integrated supply chains, and rapid iteration. As ITES China, we witness this evolution directly, where the synergy between innovative Chinese humanoid robot company actors and a mature component network accelerates practical deployment. This article examines current industrial use cases and the infrastructure that supports them.

The Integrated Supply Chain: A Catalyst for Development

The progression of humanoid robots from China is not solely about final assembly. It is fundamentally enabled by a deeply interconnected and responsive supply chain. This network provides the essential building blocks: high-torque density actuators, precision reducers, sophisticated force-torque sensors, and real-time control systems. The concentration of specialists in these domains allows for close collaboration between China humanoid robot company engineers and their component suppliers. This proximity reduces iteration cycles, facilitates custom solutions for specific payload or dexterity requirements, and contributes to cost-optimization pathways. The result is a development environment where hardware and software can be co-developed efficiently, pushing the boundaries of what these platforms can achieve in structured industrial settings.

Core Applications in Manufacturing and Logistics

In practice, the value of these platforms is demonstrated across three demanding operational areas. First, in assembly and finishing tasks, their bimanual dexterity and advanced sensor suites allow for work on complex products. They can manage sub-assembly integration, screw driving, and delicate polishing operations, especially in settings that are challenging for traditional fixed automation. Second, for quality inspection, a humanoid robot from China can be deployed. Equipped with high-resolution vision systems, these units can navigate semi-structured areas to perform visual checks, take measurements, and log data autonomously, filling gaps in stationary inspection lines. Third, within logistics, their mobility and ability to manipulate standard containers make them suitable for flexible material handling. They can load/unload machines, transfer parts between carts and conveyors, and manage replenishment tasks in warehouses designed for human foot traffic, offering a new layer of adaptive automation.

ITES China: The Convergence Point for Innovation

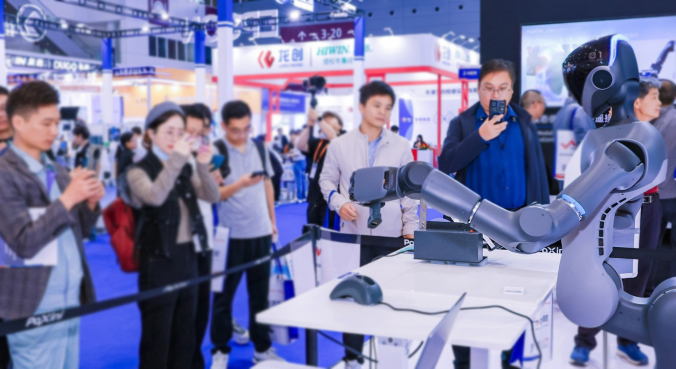

To move from understanding the theory to evaluating the physical technology, industry professionals require a dedicated forum. The Humanoid Robot Industry Chain zone at ITES China serves as this critical junction. This rapidly growing segment is curated to address the industry's move toward mass production readiness. It gathers enterprises showcasing the full spectrum of innovation, from core components to complete solutions. Attendees can examine humanoid robot platforms, dexterous hands, and robotic arms up close. The exhibition scope extends to the vital subsystems: actuation systems like joints and motors, sensing systems including LiDAR and tactile sensors, and the control systems powered by specialized chips and algorithms. This comprehensive display allows engineers and decision-makers to assess compatibility, performance, and potential integration pathways within a single, professional environment.

The pathway toward integrating humanoid robotics into industrial workflows is built on practical capability and supply chain strength. The developments emerging from the ecosystem, including numerous China humanoid robot company projects, highlight a focused approach on solving specific, high-value problems in assembly, inspection, and logistics. For any organization serious about investigating these solutions firsthand, the coming together of the entire value chain is essential. We facilitate this meeting at ITES China, where the latest generations of humanoid robots from China and their foundational technologies are presented for professional evaluation and collaboration. The event provides a direct opportunity to engage with the engineers and companies shaping this next phase of industrial automation.