How Automated Packaging Equipment Enhances Throughput and Reduces Labor Costs

【Introduction】 How Automated Packaging Equipment Enhances Throughput and Reduces Labor Costs

Operational efficiency in manufacturing is often determined at the final stage: packaging. This process, which includes sealing, labeling, weighing, and palletizing, has historically relied on manual labor, creating bottlenecks and variable costs. The implementation of automated packaging machines addresses these challenges directly. These systems replace repetitive manual tasks with consistent mechanical action, creating a measurable impact on output capacity and operational expenditure for producers of precision components and finished goods.

Direct Impact on Production Line Output and Consistency

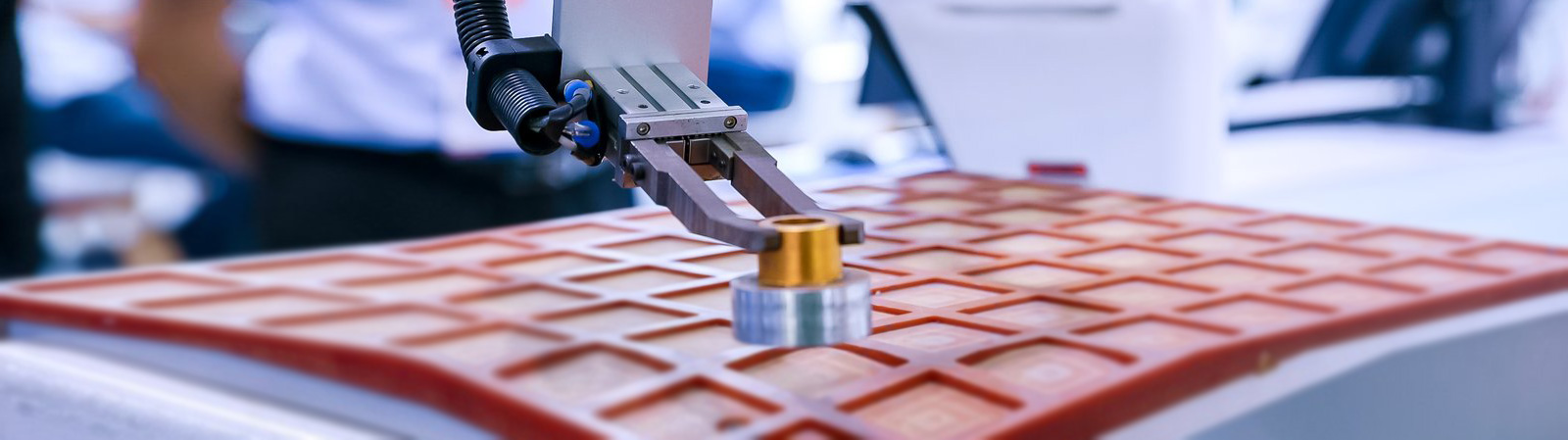

The primary advantage of automated packaging equipment is its direct contribution to increased throughput. A machine designed for high-speed sealing or automatic palletizing operates at a steady, programmable pace, unconstrained by human fatigue or shift changes. This creates a predictable and often faster flow of finished goods from the end of the assembly line into shipping containers. Furthermore, automation introduces a critical element of consistency. Manual packaging can lead to variations in box sealing quality, label placement accuracy, or stacking patterns on a pallet. Automated packaging machines execute each cycle identically, which not only improves the professional presentation of shipments but also minimizes product damage caused by insecure or uneven packaging. This reliability reduces waste and ensures that the efficiency gains from upstream manufacturing are preserved through the final logistical step.

The Manufacturing Ecosystem for Integrated Packaging Solutions

The capability to deploy effective automation in this field is supported by a specialized industrial network. A wide array of automated packaging equipment manufacturer options exists, offering solutions ranging from standalone sealers to fully integrated robotic boxing lines. This competitive and collaborative ecosystem drives innovation in machine design, particularly in developing systems that are more flexible, easier to integrate with existing conveyors, and simpler to reprogram for different product sizes. For a manufacturing business, this environment provides significant choice and allows for sourcing equipment that matches specific volume and complexity requirements. The proximity of machine builders to a vast market of users also fosters the development of practical, robust designs that are serviceable and supported by readily available technical expertise and spare parts.

The Exhibition as a Functional Showcase for Packaging Automation

Evaluating the fit and capability of these systems requires seeing them in a simulated operational context. The Intelligent Conveying & Loading/Unloading Solutions zone at ITES Shenzhen provides this exact environment. This section focuses on the smart transfer and handling of materials within production, logically culminating in the packaging phase. Here, visitors can observe a connected flow where components from automated assembly are conveyed directly to automated packaging machines. The exhibition scope is comprehensive, showcasing sealing machines, wrapping equipment, labeling systems, and robotic palletizers. At ITES Shenzhen, one can examine how different machines from various automated packaging equipment manufacturer brands interface with conveyors and control systems. It is a practical venue to compare the speed of different sealers, the precision of automated labeling heads, and the flexibility of modern palletizing robots, all within the framework of a complete material handling sequence.

The integration of dedicated machinery for packaging is a logical step for manufacturers focused on optimizing total production cost and output. Automated packaging machines deliver quantifiable gains in speed and uniformity at the critical point where products prepare to enter the supply chain. The depth and specialization of the manufacturing base for this equipment provide a reliable source for both standard and custom solutions. For operational leaders and plant engineers, platforms that demonstrate this technology in an integrated setting are key to making informed decisions. ITES Shenzhen functions as this demonstration platform, connecting the engineering of production with the practicalities of logistics. It allows for a direct assessment of how different automated packaging equipment manufacturer solutions can be applied to enhance throughput and manage costs in a real manufacturing environment.