6 Steps to Industry 4.0 in Metal Fabrication

【Introduction】 Lean manufacturing and strategic measurement build the foundation in fab shops.

Buzzwords like the Industrial Internet of Things, machine learning, artificial intelligence, and Industry 4.0 have made the rounds among the trade and popular press for years. They’re the future, apparently. So what will that future be like? Well, automation will become autonomous, self-learning and -correcting while the humans handle the exceptions—the process problems and rework—then feed that information back into the system, which will learn, become even better, and make exceptions even rarer.

Implementing Industry 4.0 doesn’t happen with the flip of a switch. It’s an evolution that, in time, will change the nature of how the metal fabrication industry and the rest of the world makes things.

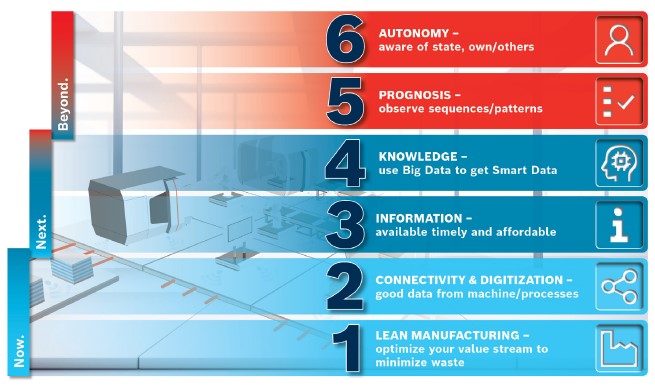

OK, so what does that look like in metal fabrication, and what can the progressive fab shop today do to work toward that autonomous future? Karl Rapp, application engineering manager, automation and electrification, at Bosch Rexroth Corp., has a good way to explain it. His explanation navigates through six steps, each one building on the others. The more robust those bottom steps are, the more effective, even revolutionary the final steps could be.

Consider a sheet metal fabricator with the epitome of laser cutting automation, a comprehensive flexible manufacturing system (FMS) with storage and retrieval towers and robotic offloading automation. It would seem that operation is well on its way toward Industry 4.0 and fully autonomous manufacturing, right?

Not necessarily. As Rapp explained, the answer depends on how firm a foundation was created by those first steps toward Industry 4.0. The weaker those steps are, the more likely a fabricator’s efforts will falter. So what does the first step involve? Interestingly, it doesn’t focus on sensors, machinery, or even automation. Instead, it’s about people.

Step 1: Lean Manufacturing

As they say, garbage in, garbage out. A shop with inconsistent or illogical processes and procedures effectively produces garbage data, at least from a high-level analytics perspective. Sure, certain data might shine a spotlight on a problem and perhaps prove to everyone that the status quo isn’t good enough. But at this point, data taken from simple observations might suffice, combined with a healthy dose of common sense. A laser cutting machine operator continually walking across the entire plant to retrieve a tool isn’t good, and no one needs sophisticated analytics to prove the point.

“That’s why establishing lean manufacturing and quality rules is the first step,” Rapp said. “You need to clean up your workplace and make sure you have lean manufacturing rules in place.”

This starts with 5S, but it also includes end-to-end process scrutiny. Fabricators aren’t paid for machine uptime; they’re paid for the products they ship. Hence, the quicker those products flow from raw stock to the shipping dock, the better. Excessive batch sizes might make a machine’s overall equipment effectiveness (OEE) uptime stats sky-high, thanks to fewer machine setups, but those huge batches will likely take a while to make it to the shipping department.

A fabricator’s lean procedures, forever scrutinized and polished, weigh material yield, machine setup times, work-in-process (WIP) buffers, and more. Shop value streams utilize kanban squares to limit WIP, and everyone maintains a relentless focus on flow.

Rapp added that lean processes and procedures should extend upstream, including raw material handling, material inspection, even vendor relationships. Someone failing to inspect or load material properly into an automated storage and retrieval system is a bad thing—but again, no one needs data analytics to discover the fact. Operator errors happen, but behind every error is a procedure that was incorrectly followed, inadequate, documented and communicated poorly, or a combination of all three. Continually perfecting those procedures builds the foundation for everything else.

“When a shop doesn’t follow the rules of lean manufacturing and it starts to gather and analyze process data, you end up with a very wide bell curve that’s basically inconclusive,” Rapp said. “It can be distracting and even useless, and it doesn’t help solve those basic problems.”

The path toward the ideals behind Industry 4.0 could follow six layers, or steps. The stronger the first steps are, the more robust the later steps can be.

Step 2: Connectivity and Digitization

Step 2 and beyond delve into the details of process monitoring and the road toward autonomous operation. Some operations have reached step 2 and perhaps a few elements of 3, 4, and 5, but the final step represents a vision for the future.

Also know that what follows describes a hypothetical fabricator with a laser cutting FMS; the specifics of what kind of sensing strategies will and won’t work of course depend on the machine design and nature of the specific operation.

Today plenty of fab shops perform uptime tracking, with sensors reporting when a machine is unexpectedly down. But as Rapp explained, this just scratches the surface of OEE’s capability. It’s great to be able to automatically sense when a machine that should be on is off, but that’s just a first step. Automated machines have multiple points for OEE measurement that divide a larger process into its individual components. For a laser FMS this might include material loading and unloading as well as various aspects of the laser cutting head’s behavior.

Rapp added that what these measurements are, where they are taken, and how they occur depend on the specific machine design and the processes involved. Regardless, his point is that OEE data—the kind that can form the foundation of the ideals behind Industry 4.0—“needs to be built from the ground up. For each process within a machine or system, you need a clear method for measuring the OEE.”

Another variable is data frequency, or how frequently a sensor (or human) records and delivers data in a useful format. Every factory gathers a range of data at different intervals. “Think about the data you might receive about worker safety,” Rapp said. “The data comes after a shift is complete, or you might see data the next morning about the previous day. That’s low-frequency data.”

Sensors measuring a machine cycle time might record data points every few minutes, after each cycle is complete. “These would be mid-frequency data,” Rapp said.

High-frequency data—which could involve laser power, assist gas pressure, or various aspects of system operation—might come every few milliseconds. These data frequencies need to be coordinated with other process variables so that data analysis can compare apples to apples.

For data to become useful, a fabricator needs context. A laser cutting machine might have umpteen data points it collects, “but all that data means nothing unless you can relate it all to the actual cutting,” Rapp said. “What part was being made on the machine? What information is coming from the manufacturing execution system (MES)? What was the date and time stamp?”

Think of every data point a sensor collects as a freeze-frame in time. You have all the intricacies of machine performance that the sensor is collecting, but you also have what the machine is doing—that is, the job it’s cutting.

Step 2 also involves connectivity. Again, customers buy products or parts, not machine uptime, so one machine or system—even one as large as a modern laser cutting FMS—is only one piece of the puzzle. Manufacturers have various ways to connect different systems using common protocols like OPC. “What’s important to know here,” Rapp explained, “is what’s doing the time stamping and how [each data point] is being documented. Does the time stamp occur at the machine controller or PC, or is it being done in a separate database? There will be small time differences, and those time differences become extremely important as it relates to when exactly a fault occurs and why.”

Consider a sheet metal fabricator with the epitome of laser cutting automation, a comprehensive flexible manufacturing system (FMS) with storage and retrieval towers and robotic offloading automation.

He added that the recording doesn’t necessarily need to be made in real time at the controller; the ideal frequency really depends on what exactly the sensors are detecting. “Regardless, those who are analyzing the data need to know how it’s time-stamped, so everyone is on the same page.”

Rapp called data frequency “a journey” that usually starts at infrequent intervals. “You don’t start by collecting high-frequency data,” he said, adding that all those data points might flood your efforts with information that isn’t needed, at least not yet. “Typical operations start with low-frequency data, then build up to higher and higher frequencies of data collection.”

The more robust step 2 is, the more effective the upper levels become. If measurements are faulty or inadequate, everything else that comes after becomes difficult, even futile. Rapp added that network technology advancements will make data collection even more robust and, hence, expand what’s possible in later steps. This includes the network infrastructure. Today’s hardwired and wireless networks, such as LANs and WLANs, “often have limits for achieving the required digital data footprint. But real-time, scheduled Ethernet and wireless 5G will eliminate these obstacles in the factory of the future.”

Step 3: Information

Data by itself can’t spur change or improvement, but improvement can occur after the data is analyzed, put into context, and translated into actionable information.

“At this point you have the data,” Rapp said. “Now you apply OEE principles. You see the total potential output of a machine. The machine produced good parts, bad parts, and some parts that are unknown [whether they are good or bad]. The goal is to eliminate the unknown, increase the good, and minimize the bad.”

Now the analysis can relate good-part and bad-part information to other process information. Some of this at first comes from a manual search, be it the raw material position, gas pressure, or other elements that could come directly from machine, software, or, not least, the machine operator.

“Machine operators have knowledge,” Rapp said. “They observe the process, and they might have made process notes about specific cutting behaviors or part tabbing or other nesting strategies that the programmer should know about.”

Add this information to related time-stamped information—the cutting conditions, gas flow, the presence of moisture (from assist gas, a humid environment, etc.) and other process parameters—and you begin to build a database. “Eventually, that database will have a digital record of every manufacturing process and part produced,” Rapp said.

Step 4: Knowledge

“Once we relate the information and use it to come up with a conclusion and remedy, that is knowledge,” Rapp said. “This knowledge then can be documented in a database or other system where people can retrieve it and use the remedy to solve similar problems.”

This information cannot be a secret, either. “If you have only two people in an entire company accessing and using information to solve problems, the situation will never work.” Everyone, or at least as many as possible, needs to be able to tap into the knowledge—be it in an MES or other system—and be familiar enough to analyze the data to solve problems or improve processes.

And like in step 3, where information gathering becomes more and more automated over time, the knowledge gained in step 4 starts as a manual process and then, through machine learning, becomes more automated. Eventually automated operation begins to take on autonomous qualities.

Here’s where edge and cloud computing steps into the picture. Most problems in manufacturing processes are time-sensitive, hence the importance of the time stamp with every data point. This, Rapp said, is why the complementary nature of edge and cloud computing is so critical. Oversimplified, edge computing uses the power of a cloud server’s neural networks, but on a local computer or control system.

Consider a video feed from a camera inspecting cut parts as they emerge from the FMS, where (just to use a hypothetical example) robots pick the cut parts and place them onto a conveyor. “In this case, it’s very difficult to stream real-time video into the cloud,” Rapp said, “so I use an edge computing device running the vision-inspection machine learning model that’s connected directly to the camera.”

Technicians and operators work with the machine or vision analytics system to teach the critical variables of an operation, like what a good part edge is versus a bad part edge, and what the acceptable tolerance windows are for which part. Each part could have a laser-etched QR code, which would allow the system to correlate the quality observation (edge condition) with the job operation information available, including full details about every upstream process, such as the raw stock it came from.

The more knowledge a system has, the greater the potential for further automation with machine learning. And the ideal is for the machine’s “digital” knowledge base to become ever broader, to incorporate so much data and information that the analytics achieved with machine learning could determine solutions that people wouldn’t have considered otherwise.

Step 5: Prognosis

Once you attain machine learning, “you can then see the curves of where you’re going,” Rapp said. “You can predict the trajectory.” Are conditions getting worse, and if so, when will they become so bad that parts will begin to go out of tolerance? A good prognosis will tell you.

As with step 4, prognosis can be manual at first, with technicians analyzing current data and interpolating it with software to predict future performance. But as machine learning evolves with ever more real-time data recording and analysis, the systems themselves can make these prognoses and either take corrective action before problems occur or shut down (or alter course in some other way) when a certain limit is set (like, say, an edge quality tolerance for a specific material or part batch).

Step 6: Full Autonomy

This step, Rapp said, is a vision that might be what a fabrication plant with a fully mature Industry 4.0 implementation could look like. Popular perceptions of a smart manufacturing plant with “connected” machines bring up images of fabrication equipment communicating along their entire value streams, with information flowing from laser cutting to bending to hardware insertion and final assembly.

But that’s not how Rapp described it. “Imagine I have a manufacturing plant, and the only connection I have between one machine and another is the workpiece itself.” Rapp clarified that “using real-time Ethernet for scheduled, reliable information exchange, all machines are connected to a central MES. The MES of the future will use machine learning methods and the digital data for smart, real-time value stream decisions.” Still, the machines have no need to talk to each other directly—just the MES, the “brain” of the future fab shop.

Rapp sees a fully autonomous plant become much more flexible, not limited to rigid process-specific departments or value-stream layouts. In the connected plant, all required materials and workpieces will follow the path that makes best use of the entire operation’s available capacity. Job routings could change on-the-fly as AGVs move material, tools, and cut parts to where the processing capacity is, exactly when they’re needed.

Imagine a stack of laser-cut workpieces being carried on an AGV and arriving at an automated press brake, which, after scanning it, opens a connection to the MES with neural networks, the plant “brain.” The brain reveals the product and customer information from the MES, but it also reveals data from upstream machines previously shared when they processed the part, as well as information from a vision system that detects the actual part sitting on the AGV. Knowing all this, the brain instructs the press brake to take the best possible action.

Perhaps the cutting operation’s process variables were slightly off the norm, or maybe the piece was nested with instead of against the grain of the sheet metal. Maybe the cut piece, due to the release of stress after being cut from the skeleton, isn’t entirely flat. The connected machine adjusts the bending process to suit, tweaking everything from the bend sequence and the robot’s gripper selection to the paths the robots take to orient and form the workpiece. In an autonomous world, machines configure themselves.

They do it by tapping into machine learning and automated analytics, knowledge built on what Rapp calls a “continuous digital footprint” as the workpiece travels through every manufacturing step. This, ultimately, is how a factory becomes smart.