Cabinet unit price exceeds 10 million yuan, annual output over 40,000 units! Precision sheet metal leaps forward riding the east wind of AI servers

【Introduction】 Metal Forming Machine Tools、Stamping/Sheet Metal Automation、“AI Server

Introduction

The global AI server market is experiencing explosive growth, and the demand for precision sheet metal processing is accelerating.

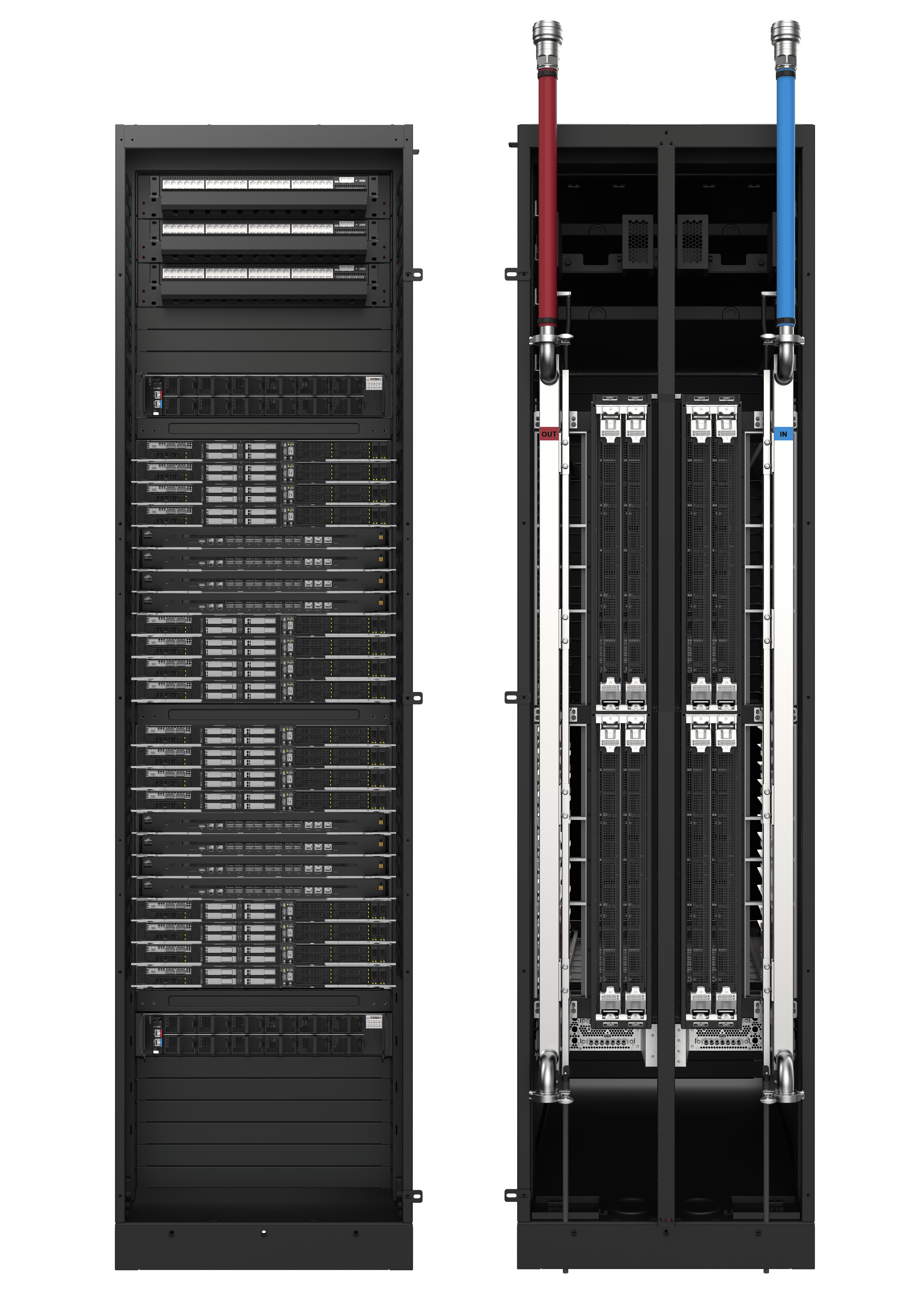

A cabinet priced at 3 million US dollars (approximately 21.66 million RMB) – this is the new price tag set by NVIDIA NVL72 for the computing power era. Behind it, a 100-billion-level industrial chain storm triggered by AI computing power is sweeping in.On one hand, driven by the rigid demand for low latency in 5G, the Internet of Things (IoT), and autonomous driving, computing power is accelerating its shift to the network edge. This has spawned an urgent need for customized edge server cabinets that are miniaturized, modular, and easy to deploy. On the other hand, the production and sales of server products are robust. For example, the annual output of NVIDIA DGX GB200 is expected to reach a maximum of 40,000 units...The explosive growth momentum of the global AI server market is being transmitted upstream along the industrial chain, ultimately focusing precisely on the core track of precision sheet metal processing.

AI Servers Ignite Demand in the Sheet Metal Market

Why is there a window of opportunity in the precision sheet metal processing market behind high-computing-power AI servers?

Our research shows that in the first half of this year, OEM supply chain enterprises for servers, such as Huaxian Intelligent Manufacturing, Xianghua Technology, Dalong Hardware, and Yangtian Electronics, have been continuously receiving a surge in orders. Some enterprises anticipate that the shipment volume of sheet metal structural parts for GPU servers will exceed 400 million RMB this year. Yang Qiling, Executive Vice President of Quanta Computer, also stated that benefiting from the continuous explosion of AI demand, Quanta has been continuously shipping NVIDIA products. The latest generation of GB300 products will enter the main volume release period in November and December. This year, production has been expanded 8 times, yet supply still falls short of demand.

This is by no means an isolated case; it is supported by the strength of a hundred-billion-dollar market. The global AI server market is expected to reach 158.7 billion US dollars in 2025, with a year-on-year growth of nearly 27%. From precise laser cutting to efficient servo bending, and then to automated welding and grinding – the entire precision sheet metal processing equipment chain has been fully activated.

.jpg)

Three Major Challenges Remain in Sheet Metal Part Processing

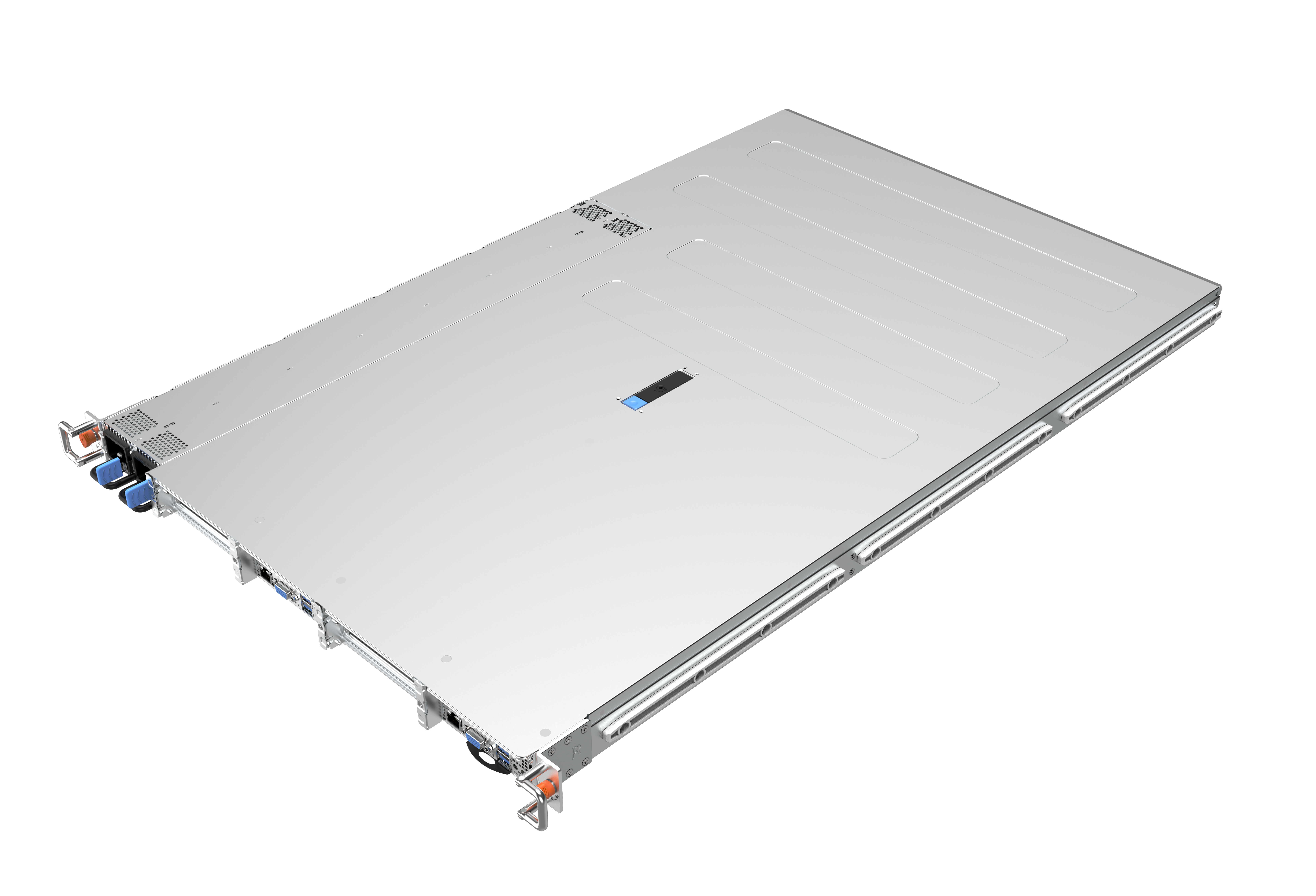

The high-performance and high-density deployment characteristics of AI servers impose much stricter requirements on internal sheet metal structural parts than traditional servers. From server chassis/cabinets, power supply enclosures to temperature-controlled heat dissipation cabinets, the precision, strength, sealing, and heat dissipation performance of these key components directly affect the operating efficiency and stability of AI servers.

Chassis/cabinets/subracks serve as the basic framework of AI servers and need to provide high structural strength support (with a total weight capacity of over 1,500 kg). To achieve excellent electromagnetic shielding effectiveness, precise sheet metal splicing and conductive treatment are required to reduce electromagnetic interference and ensure stable computing power output. The dimensional tolerance must be controlled within ±0.03 mm to ensure accurate docking of multiple modules and adapt to high-density component installation, thereby guaranteeing stable equipment operation.

Power supply enclosures are key carriers for improving the power density of AI servers. As the power supply of AI servers increases from the traditional 500W to over 3000W, the enclosures need to have efficient heat dissipation capabilities. Through the integrated design of heat dissipation fins, heat dissipation efficiency is significantly improved; precise hole opening positions are matched to prevent leakage risks.

With the accumulation of computing power, solving heat dissipation problems has become a top priority. The temperature-controlled sheet metal parts in temperature-controlled heat dissipation cabinets have extremely high process requirements: laser welding technology is required to achieve seamless splicing, and the liquid leakage detection accuracy must be controlled below 0.1 ml/min; the internal flow channel structure is complex, and 3D laser cutting is used to process special-shaped flow channels to ensure uniform distribution of cooling liquid; at the same time, they need to withstand the impact of high-pressure cooling liquid, with a structural strength meeting the high-pressure resistance standard of 1.5 MPa.

From the processing requirements of the above structural parts, three important technical challenges are evident:

First,it is difficult to meet the requirements of extreme precision and consistency. Some complex structures, such as liquid-cooled flow channels, have higher processing precision requirements. Traditional manual operations or semi-automated equipment struggle to ensure precision consistency in mass production.

Second,the processing capability for complex structures needs to be improved. For subracks and cabinets with multi-layer splicing structures, the coordination requirements for processes such as cutting, welding, and bending are extremely high. Traditional processing equipment has insufficient flexibility and cannot adapt to the processing needs of complex shapes.

Third,the contradiction between large order fluctuations and flexible production is prominent. AI server orders are characterized by "large batches, multiple varieties, and urgent delivery". Traditional production lines have long mold change times, making it difficult to quickly respond to order changes, and there is a high demand for equipment automation.

Sheet Metal Equipment Takes the Lead in Mastering Precision and "Intelligent" Manufacturing

In response to the sheet metal factories' demand for "needing precision, efficiency, and flexibility simultaneously", what innovative applications are there on the equipment side? In fact, before the outbreak of AI server demand, many sheet metal equipment manufacturers had already begun to lay out and propose targeted process solutions.

(I) Basic Processing: Laying a Solid Foundation for Precision

Precision Cutting: Yike EKO launched the high-precision laser composite processing machine ELC1212V, which features AI visual automatic identification and positioning. It can process 0.3 mm apertures with high precision, achieving a yield rate of 99.8%. Compared with imported equipment, the processing cost is reduced by 40%, and the delivery cycle is shortened by 80%, solving the problems of numerous processes and low efficiency in traditional sheet metal processing. In addition, enterprises such as Dineng Laser and Hansonggu provide high-power, high-precision laser cutting equipment, which serves as the foundation for realizing laser hole drilling and hollowing of complex shapes.

Addressing Sheet Metal Deformation: Mahart's servo hydraulic thick plate high-precision leveling machine MHTY100 series ensures that the leveling gap remains constant throughout the leveling process, fundamentally improving the leveling precision of sheet metal. No roller marks are left on the material surface. Zhong'an's CNC leveling machine and Xinlijin's fully automatic leveling machine also realize seamless connection from leveling to blanking, improving production efficiency.

Refined Deburring: Xiangsheng's robotic deburring workstation uses visual positioning technology to accurately process the edges of cabinets after laser cutting, with a deburring precision of 0.01 mm. Additionally, deburring solutions from Zengdao, Linus, and Weiterui efficiently process cutting edges, meeting the strict requirements of no sharp corners and no residues inside.

(II) Forming and Integration: Improving Efficiency and Stability

Intelligent Bending and Forming: Lanhao's LHA06-A series flexible bending center adopts 21-axis + full electric servo control and is equipped with universal bending dies. The fastest speed per cut is 0.2 seconds, and multi-edge bending can be completed in one operation. Solutions from Yike EKO, Avid LVD, Aosima, Hawei Intelligence, and Leigesi also ensure consistent precision in multiple bending operations, meeting mass production needs.

Automated Production Line Integration: The CNC punch automatic production unit in Gutaike's intelligent flexible production system (FMS) can reduce the standby time of punch presses and improve equipment utilization. Estun and Beiwen Automation have also innovated sheet metal automation units and production lines, significantly improving production efficiency and stability.

Intelligent Riveting: Rui'ente's intelligent riveting center targets the threaded connection of server sheet metal, with a riveting precision of ±0.02 mm and a 20% increase in riveting strength. Nasi's fully automatic riveting machine supports simultaneous riveting at multiple stations, increasing production efficiency by 50%. Yipeng and Ruitel also offer similar intelligent riveting center solutions.

Laser Welding: Han's Laser's fiber laser welding machine has a welding speed of 3 m/min, a weld width error of ≤0.1 mm, and a strength reaching 95% of the base metal. In addition, high-precision laser welding technology solutions proposed by Pudian Welding, Nai'en Laser, Youkong Laser, and Lanlian Laser have also realized firm and aesthetic connections between sheet metal parts.

Surface Treatment and Grinding: Guorunde's G230A five-axis CNC grinding machine is mainly used for grinding weld scars on the surface of sheet metal workpieces and the sprue burrs of castings, and holds 21 technical patents. Furthermore, automated grinding solutions from Deli Grinding and Maishike have significant advantages in handling welding marks and surface smoothness.

It is worth mentioning that the above-mentioned enterprises will also showcase their latest products and industry-specific solutions at the ITES Shenzhen Industrial Exhibition at the end of March next year.

The ITES-themed exhibition - Metal Plate and Pipe Processing Technology Exhibition focuses on addressing the extreme challenges of cost reduction and efficiency improvement in the processing of metal plates and pipes in fields such as new energy, automobile manufacturing, communication electronics & servers, machinery manufacturing, and sheet metal hardware products. It centrally displays leading process technology equipment and automated intelligent solutions for sheet metal, stamping, welding, pipe/profile processing, stainless steel processing, and surface treatment, achieving full coverage of the sheet metal processing technology and automated solution ecosystem, and providing a one-stop technical docking platform for the industrial chain.

.jpg)

If you also want to enter the AI server market, display innovative solutions for related sheet metal processing, or have in-depth contact with leading enterprises such as Foxconn, ZTE Communications, Vertiv Technology, Huaxian Intelligent Manufacturing, and Legend Holdings to explore cooperation opportunities, please scan the QR code to contact us and reserve your prime booth at the exhibition immediately!