The New Trend of 5-Axis Machining Lies in the Minute Details of Tens of Thousands of Micropores on Shower Heads

【Introduction】 Metal formingi ng machine tools 、5-axis machining 、precision machining

Introduction: As Semiconductor Shower Heads Drive Upgrades, What Rigorous Challenges Does 5-Axis Machining Face?

Where is the next key stage in the global semiconductor competition? Perhaps the development path of China’s semiconductor industry does not solely rely on lithography machines, which are in the spotlight and determine the success of advanced chip manufacturing processes. There are also core links in the industrial chain that were once regarded as "supporting roles" but are equally crucial. The recent breakthrough by a subsidiary of Sicarrier has highlighted the importance of such core components: it launched the world’s first 90GHz bandwidth ultra-high-speed oscilloscope and fully independent EDA software. The Product Line Director of Oscilloscopes at Longsight Technology Co., Ltd. even emphasized at the press conference the key role of precision manufacturing in this industrial chain breakthrough.

Among these core parts of semiconductor equipment, there is one that directly determines the yield rate (success or failure) of wafers—it is the **gas shower head** (also known as gas distribution plate). According to QYResearch data, the global shower head market exceeded $1.193 billion in 2024, with a compound annual growth rate (CAGR) of 7.1%, and is expected to rise to $1.91 billion by 2031. Among them, the Chinese market is leading the Asia-Pacific region with an astonishing growth rate of 25%.

Behind this multi-billion-dollar market, the focus of industry competition is no longer on solving the existential problem of whether products "exist" or not, but has shifted to the question of "how precise" they are—a question that determines who will ultimately win: How to push the process to the extreme? How do shower heads influence wafer yield? How do precision machine tools achieve highly uniform micropore machining at the "peak of micrometers"?

The Underrated Shower Head: Determinant of Wafer Yield

The seemingly unremarkable shower head (also called gas distribution plate) is a core gas distribution device that runs through key semiconductor manufacturing processes such as cleaning, etching, and deposition.

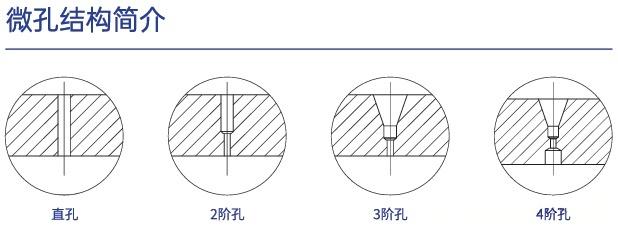

It directly determines process accuracy and chip quality. Take processes below 3nm as an example: the thickness deviation of the film on the wafer surface must be controlled within ±0.1nm, while the aperture tolerance of the tens of thousands of micropores (with apertures ranging from 0.2 to 6mm) on the shower head must be less than ±1μm, and the inner wall roughness (Ra) must be < 0.2μm. Any tiny burr or flow deviation will lead to uneven etching/deposition, directly resulting in the scrapping of the entire wafer.

Currently, the global high-end shower head market is mainly dominated by Applied Materials (AMAT) of the United States and Tokyo Electron (TEL) of Japan, and the localization rate of China’s domestic market is still less than 30%. Against this backdrop, if local suppliers want to gain a differentiated advantage in the semiconductor shower head field, the key lies in breaking through core technical barriers such as micropore precision control and brittle material machining—this also highly depends on the support of high-end precision machine tools.

The Ultimate "Ubiquitous" Challenges: What Makes Shower Head Machining Difficult?

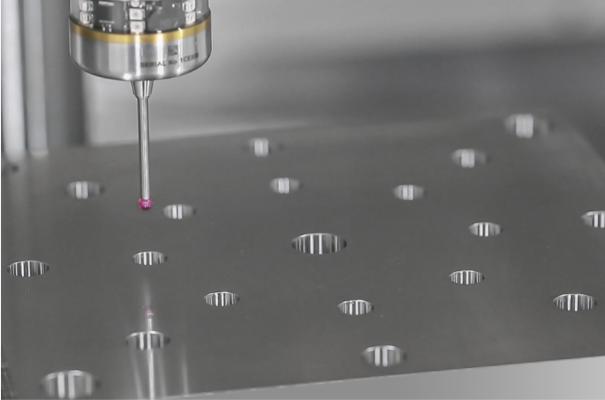

During the wafer reaction process, the dense micropores, pore structures, gas paths on the shower head surface, and the film layers in different areas of the wafer all need to ensure high uniformity and consistency. Therefore, in addition to extremely high requirements for cleanliness and corrosion resistance, there are also strict demands on aperture consistency and the absence of burrs on the inner walls of small holes.

As a result, among the most critical links in shower head manufacturing, “micropore precision control” and“hard and brittle material machining” are the two most prominent difficulties—and both steps impose strict requirements on ultra-precision 5-axis machining centers.

Increased Difficulty in Hard and Brittle Material Machining In addition to conventional shower heads made of materials such as aluminum alloy and monocrystalline silicon, hard and brittle materials like ceramics and CVD-SiC are often used to cope with extreme environments. These materials are highly sensitive to machining, prone to edge chipping at the hole opening, and cause significant tool wear. This requires the machine tool to not only have sufficient rigidity but also possess special process capabilities for difficult-to-machine materials.

Balancing Consistency and High Aspect Ratio Hole Precision The diameter deviation of tens of thousands of micropores must be less than ±0.5μm. Minor vibrations during machining, tool wear, or issues such as insufficient rigidity of the drill bit and uneven cutting force in traditional drilling processes can easily lead to defects like hole taper and hole expansion, undermining batch consistency. For micropores with an aspect ratio (depth-to-diameter ratio) of more than 20:1, it is necessary to solve the problem of hole wall collapse caused by difficult chip evacuation. This places extreme demands on the precise control of special processes and tools, as well as the machine tool’s positioning accuracy and repeat positioning accuracy.

Dual Challenges of Complex Flow Channels and Special-Shaped Surfaces The interior of a shower head is often not composed of simple straight holes, but includes complex gas flow channels and special-shaped curved surfaces to ensure that the gas has achieved preliminary pressure equalization and distribution before reaching the micropores. This requires machining equipment to be capable of 5-axis simultaneous spatial milling for precision machining of complex 3D structures.

The Ultimate Pursuit of Burr-Free Cleanliness Inside Holes Roughness on the inner wall can disrupt the laminar flow of the shower head, creating turbulent flow and affecting uniformity. In particular, detached burr particles that fall into the reaction chamber will directly become fatal defects on the wafer, turning a large number of chips into defective products and directly reducing the yield rate of the entire production process. This places extremely high demands on the machine tool’s cutting technology, vibration control, and chip evacuation capabilities.

What Technological Breakthroughs Are Leading Original Equipment Manufacturers (OEMs) Making?

In the field of high-precision shower head machining, leading OEMs are leveraging differentiated technologies to overcome the difficulties of hard and brittle material machining and micropore precision, thereby seizing market share.

Yamazaki Mazak: The SMOOTH Vibration Cutting technology of its PALLETECH system enables vibration cutting functions through MAZATROL CNC systems (such as SmoothAi and SmoothG). This can effectively break chips of difficult-to-machine materials, reduce chip entanglement, and is suitable for the high-precision requirements of shower head micropore machining. Its MEGA TURN series and FJV series (BT50) support brittle material machining, preventing tiny chips and sludge generated during the machining of brittle materials like quartz glass and graphite from entering the system, and can machine the precision flow channel structures of shower heads.

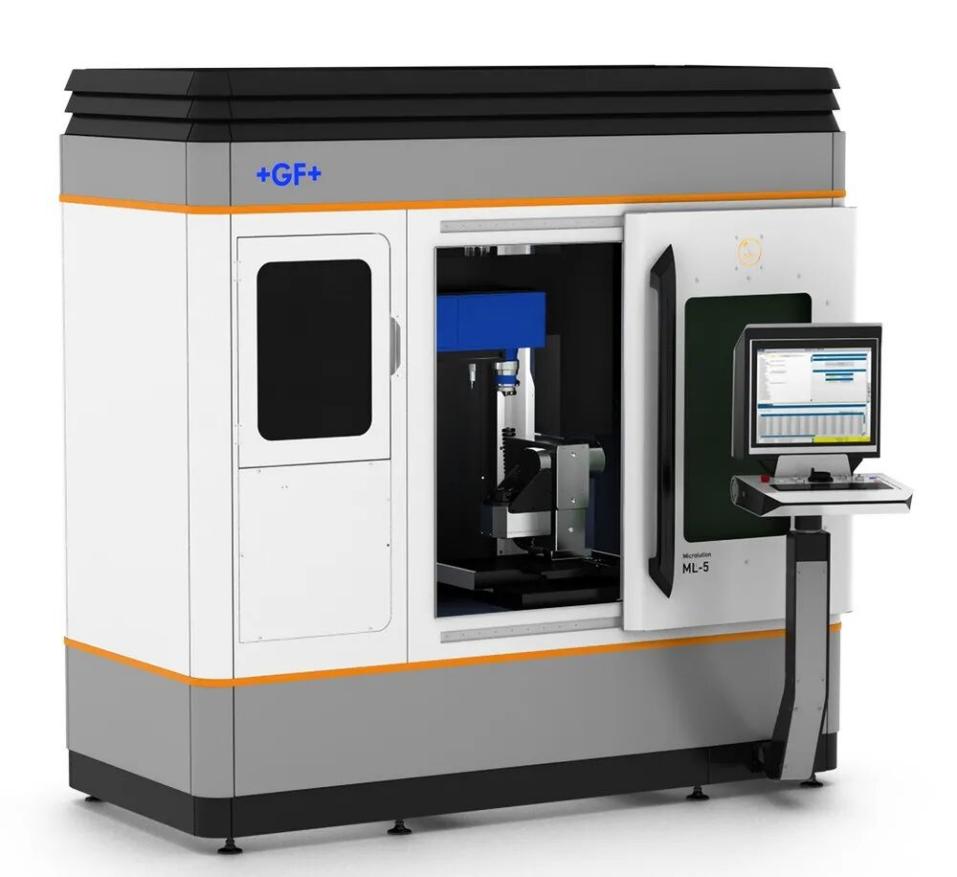

GF Machining Solutions: The ML-5 model of its Microlution product series can easily meet the ultra-fine machining needs for apertures ranging from 0.025 to 0.5mm, achieving extreme control of aperture accuracy within ±2μm. It can machine holes with an aspect ratio of up to 10:1, and the aperture position accuracy is less than 2μm. Additionally, it can efficiently machine product contours and other geometric features without tool wear or heat-affected zones, making it suitable for high-precision micropore machining of semiconductor hard and brittle materials.

Beijing Jingdiao: Its JDHGMG600 3-axis high-speed grinding center has micrometer-level precision machining capabilities. It is not only proficient in grinding brittle materials such as glass, ceramics, and silicon but also can achieve precision grinding with an accuracy of 2–5μm.

Taking monocrystalline silicon shower plates as an example, when paired with PCD drills, the JDHGMG600 can machine micropores with an aspect ratio of up to 28:1, while controlling both the aperture size and spatial relative position accuracy within ±10μm, and ensuring no edge chipping or cracks at the hole opening.

Notably, at the ITES Shenzhen Industrial Exhibition – Metal Cutting Machine Tool Exhibition at the end of March next year, in addition to Yamazaki Mazak, GF Machining Solutions, and Beijing Jingdiao, companies such as Makino, Genesis Machinery, Qiaofeng Intelligent, Langen Precision, Hanrui Kete, Xicun, Xianghui, Guilin Guibei, and Anda will also showcase their latest products and semiconductor-related industry solutions. Stay tuned!

ITES Sub-Exhibition – Metal Cutting Machine Tool Exhibition: Targeting high-precision, high-efficiency, and high-stability machining scenarios in the production of precision parts, it focuses on machining applications for complex curved surfaces such as special-shaped parts, box-type components, shaft parts, and plate parts. It achieves full coverage of the machine tool ecosystem for ultra-precision mechanical machining, including advanced manufacturing technologies, 5-axis machine tools, gantry machine tools, and core functional components, providing a one-stop technical docking platform for the industrial chain.

If you are also interested in the semiconductor industry chain and have innovative solutions for related precision machining and want to engage in in-depth interactions with leading enterprises such as CSOT, Osram Opto Semiconductors, BYD Semiconductor, Kanghui Semiconductor, AMEC, and Changyuan Technology to explore cooperation opportunities, please scan the QR code to contact us. Secure your spot at the 2026 ITES Shenzhen Industrial Exhibition and reserve your prime booth now!

.jpg)