Automation Core Component Factories, 50,000 Equipment Integrators Gather Here for Selection!

【Introduction】 Industrial Control Technology、 New Energy Equipment、 Industrial Control Automation、Power Transmission Automation Techno

Introduction: Surging Equipment Demand & Widening Component Shortages – How Can Automation Part Manufacturers Seize the Opportunity? ITES Shenzhen Industrial Exhibition Has the Answer.

To provide more valuable content services, ITES Shenzhen Industrial Exhibition has specially launched "Exhibition In-Depth", a more vertical, professional, and exclusive exhibition research column. In the 4th issue, we focus on the "Industrial Control and Mechanical Transmission Technology" exhibition area of ITES Shenzhen Industrial Exhibition.

Core components are facing cost reduction and quality bottlenecks, while non-standard docking encounters "high walls".

With the accelerated advancement of intelligent manufacturing today, the selection, adaptation, and sourcing of automation parts have become efficiency challenges and innovation constraints for equipment enterprises.

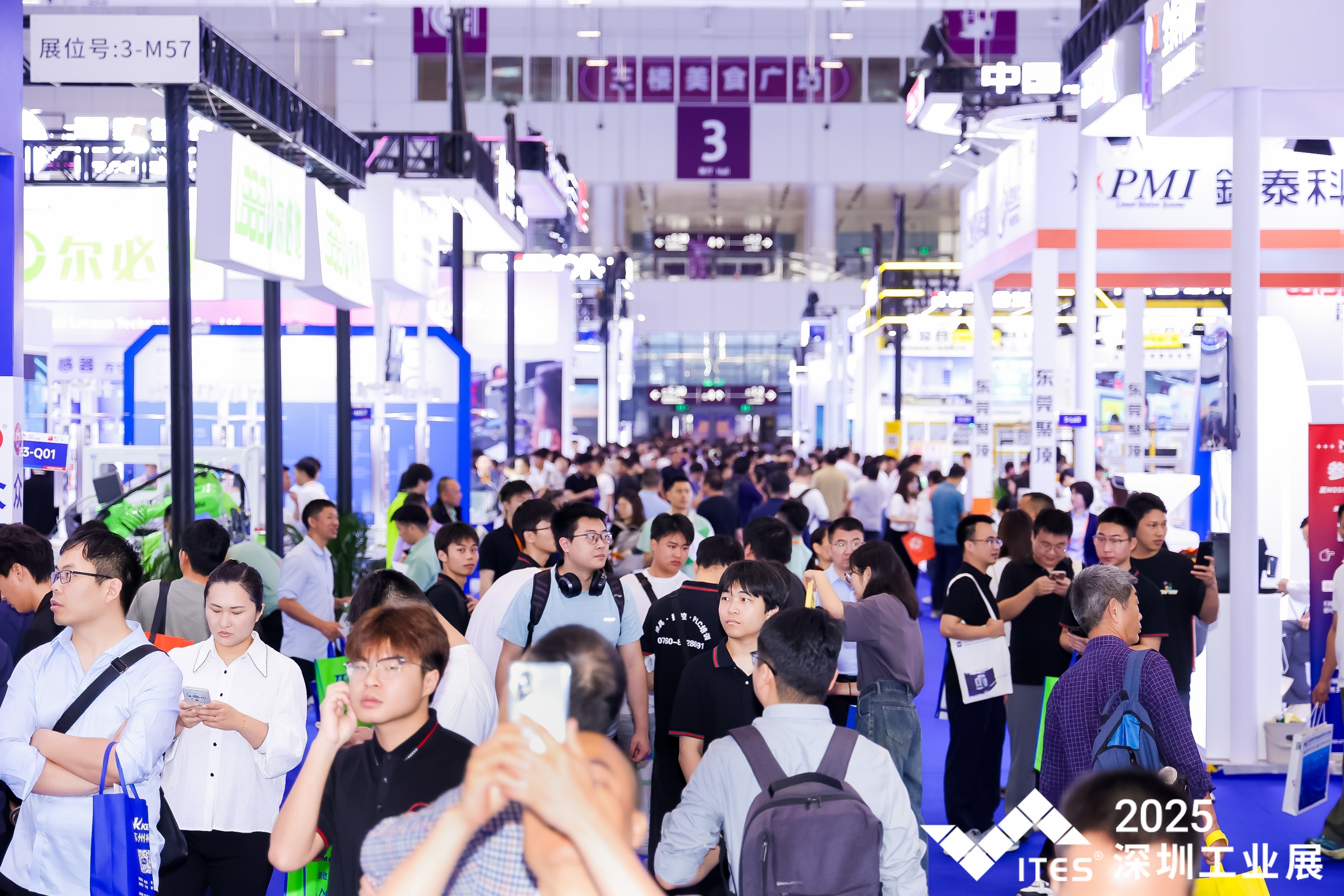

Every late March, the "Industrial Control and Mechanical Transmission Technology" exhibition area under ITES Shenzhen Industrial Exhibition gathers multiple core segments such as motion control, sensing technology, connection technology, transmission systems, and precision parts, fully covering the key links from selection, adaptation to sourcing. This is not only a window for technology display, but also the most solid and complete industrial bridge rooted in South China, connecting equipment manufacturing enterprises and component source manufacturers.

Industrial Control and Transmission Become "Rigid Demands" for Industrial Upgrading – The Market Enters a Boom Period

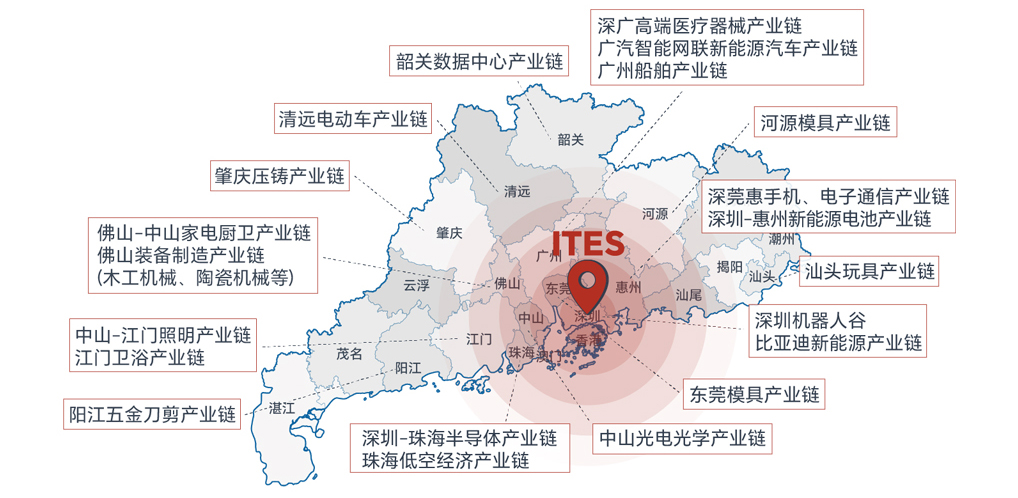

Currently, the global manufacturing industry is accelerating its transformation towards "intelligence, precision, and high-end". Relying on its dynamic economic ecosystem and intensive industrial layout, the Guangdong-Hong Kong-Macao Greater Bay Area has become a core growth engine driving the development of China's intelligent manufacturing. Strategic emerging industries such as electronic information, new energy (lithium battery), semiconductors, humanoid robots, and aerospace are highly concentrated here, forming a complete industrial chain from core components to whole-machine manufacturing.

Taking the new energy lithium battery industry as an example, over 70% of the world's lithium batteries are produced in China, and the Greater Bay Area gathers leading battery enterprises such as CATL, BYD, and Sunwoda, as well as hundreds of supporting manufacturers. The humanoid robot industry has also received dual support from policies and capital – the Greater Bay Area is home to 57% of China's humanoid robot supply chain enterprises, and the demand gap for high-torque servo motors and precision reducers continues to widen.

The rapid development of these industries has directly spawned massive demand for high-end equipment, special-purpose equipment, and automation equipment. As the "brain" and "skeleton" of equipment, industrial control (such as numerical control systems, PLCs, servo drives) and mechanical transmission (such as precision screws, guide rails, bearings) are core links that determine equipment performance, precision, and stability, thus naturally becoming high-demand products.

At the same time, the market demand in the industrial manufacturing field is strong, and the localization process of core technologies is accelerating. However, the problem of "stuck necks" in core components remains prominent. In the past, high-end numerical control systems and precision transmission components relied heavily on imports, leading to high costs, long delivery cycles, and delayed after-sales responses, which severely restricted the release of enterprise production capacity.

Meanwhile, automation equipment involves multiple links such as control, sensing, connection, and transmission. The selection of parts often requires docking with multiple suppliers, resulting in cumbersome processes, low efficiency, and compatibility risks that further affect the performance of the whole machine.

To adapt to the rapidly evolving production capacity demands, enterprises' demands for "cost-effectiveness, localized services, and one-stop selection" have become increasingly strong. This is also the important original intention of ITES to deepen its presence in this field and build a one-stop selection platform.

Building an "End-to-End + Scenario-Based" Exhibition Area to Meet One-Stop Selection Needs

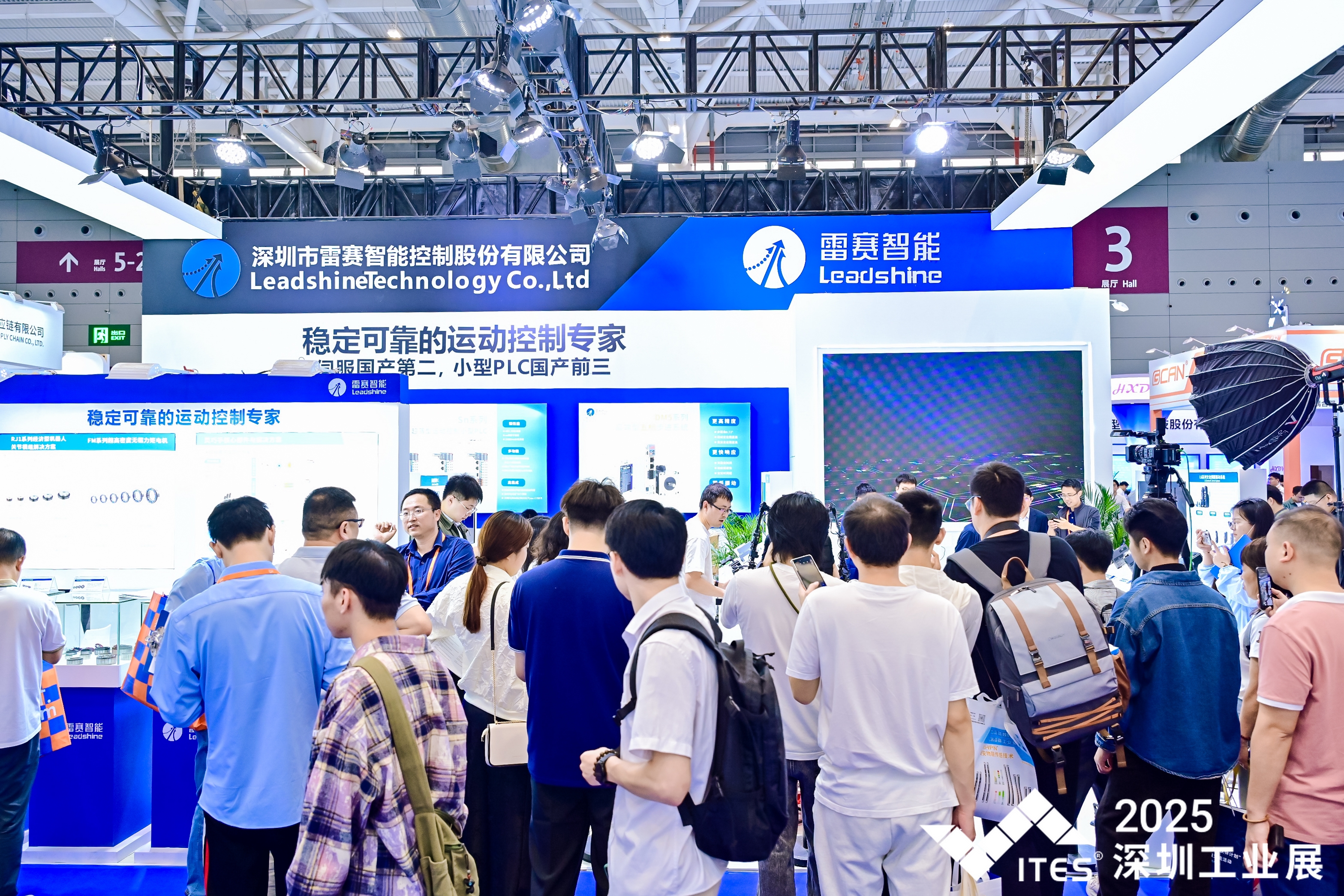

The ITES Robot and Automation Equipment Exhibition has maturely built a professional exhibition segment – the Industrial Control and Mechanical Transmission Technology Area, focusing on "motion control, sensing technology, connection technology, and mechanical transmission technology". It covers the complete supply chain of intelligent manufacturing and provides dual value of "displaying core technologies + developing equipment manufacturers" for automation component enterprises.

Rooted in South China for 27 years, ITES now gathers 637 high-end equipment enterprises and 543 robot and automation equipment enterprises every year. More importantly, nearly 30% of the 120,000 buyers present are equipment manufacturing enterprises, fully meeting the needs of component manufacturers to develop orders.

The exhibition particularly takes "lithium battery, semiconductor, electronic manufacturing, and automation equipment" as key service industries, and effectively builds a "scenario-based" collaborative display platform to make hard-core technologies "visible and usable".

So, how do these technologies connect with desired buyers through industrial applications?

(I) Lithium Battery Equipment: Control Technology Empowers Efficient Production

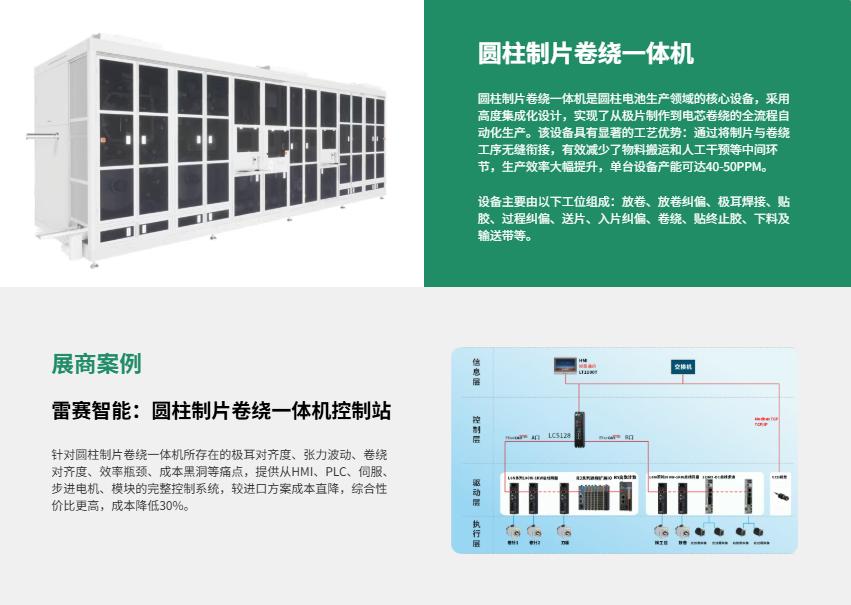

For example, industrial control and transmission technology are rigid demands in the lithium battery equipment industry. Especially for the production of cylindrical batteries and prismatic batteries, the requirements for equipment precision, speed, and stability are extremely high. Taking the cylindrical electrode sheet winding integrated machine as an example, this equipment is the core of cylindrical battery production and needs to realize the full-process automation of "unwinding - tab welding - tape application - winding - blanking", which is inseparable from high-precision control and transmission technology.

The motion control segment of ITES covers core control components such as numerical control systems, industrial computers, controllers, I/O modules, PLCs, inverters, servo drives, motors, and pneumatic/hydraulic components. It specifically provides selection references for core functional components for special-purpose equipment (lithium battery/semiconductor/electronic manufacturing, etc.), automation equipment (system integration/assembly/polishing & grinding/welding/visual inspection/logistics packaging equipment, etc.), and high-end equipment (metal cutting/metal forming).

(II) Semiconductor Equipment: Sensing Technology Breaks Through Precision Bottlenecks

Modern semiconductor manufacturing has extremely high requirements for precision, requiring sensing technologies (such as pressure sensors, Hall sensors, etc.) to achieve high-precision monitoring and control. For instance, the measurement error of film thickness at the 7-nanometer process node must be controlled at the angstrom level (1 angstrom = 0.1 nanometer) to ensure process stability and equipment safety.

The sensing technology segment of ITES includes industrial sensors, industrial safety solutions, encoders, etc. It provides core functional component products and solutions such as industrial sensors, industrial safety solutions, and encoders for automation equipment (system integrators/assembly automation/polishing & grinding automation/welding automation/inspection automation/logistics equipment, etc.) and special-purpose equipment (lithium battery/semiconductor/electronic manufacturing/packaging equipment, etc.).

(III) Photovoltaic Equipment: Connection Technology Facilitates System Integration

Photovoltaic equipment transmits electrical energy between modules and inverters through connectors. For example, MC4 connectors adopt a plug-and-play design, which can quickly connect photovoltaic modules in series or parallel to form an efficient power generation network. Without connection technology, each module would need to be directly connected to the inverter, resulting in messy cables, high installation difficulty, and reduced reliability.

The connection technology segment of ITES includes products such as connectors for high-end equipment, automated production lines, and lithium battery/semiconductor equipment. It directly addresses technical pain points in popular fields such as new energy vehicles, 3C electronics, and smart factories, and provides high-reliability, high-voltage-resistant, and anti-interference connection solutions.

(IV) Medical Equipment: Transmission Technology Accelerates Localization Replacement

In recent years, with the increase in domestic R&D investment and the improvement of technical level, the process of localization replacement has accelerated significantly. The localization rate of domestic medical reducers was approximately 45% in 2023 and is expected to exceed 70% by 2025.

As a core component of medical equipment, transmission parts directly affect the overall performance and medical effects of the equipment. High precision, high stability, and high safety of transmission parts are indispensable. At the same time, with the trend of miniaturization and intelligence of medical equipment, lightweight, integration, and strict compliance standards have also become important requirements.

The mechanical transmission technology segment of ITES focuses on core transmission components such as screws, guide rails, bearings, and modules, which feature high precision, high rigidity, and long service life. It provides equipment manufacturers and integrators with core functional solutions and selection references to improve performance, ensure reliability, and realize complex movements.

Building an In-Depth Supply-Demand Cycle and Linking Full-Industry Resources

The "Industrial Control and Mechanical Transmission Technology" area of ITES Shenzhen Industrial Exhibition attracts leading enterprises in the industrial chain such as Jiejia Weichuang, Hymson, Lianying, Zhongke Feice, Xinkailai, Xidian Semiconductor, Sirong Equipment, Changyuan Group, and Liande Equipment to visit and select products every year, accurately empowering enterprises in technological innovation and market expansion.

If you are concerned about the selection of automation parts, want to deeply develop the South China equipment market, and find a shortcut to connect with leading enterprises, you must not miss the 2026 ITES Shenzhen Industrial Exhibition. Reserve your prime booth now!