Advanced Sheet Metal Fabrication Solutions: Trends to Watch at ITES 2026

【Introduction】 Advanced Sheet Metal Fabrication Solutions: Trends to Watch at ITES 2026

The drive for greater efficiency and cost management defines current priorities in industrial manufacturing. ITES 2026 establishes a dedicated zone to confront these operational challenges directly within the realm of China metal sheet fabrication. This segment of the exhibition is built around a clear objective: presenting actionable technologies that address the entire processing chain for sheet metal, tubes, and profiles. We structure this zone to serve professionals from sectors where these materials are fundamental, including new energy, automotive, communications electronics, and medical device production. The concentration of specialized exhibitors at this event provides a focused environment to evaluate the next wave of productivity-enhancing solutions for China metal sheet fabrication processes.

.png)

Integration of Automation and Intelligent Systems

A visible trend involves the move from standalone machinery to connected, intelligent production cells. At ITES 2026, exhibits will demonstrate how automation bridges individual processes like punching, cutting, and bending. These integrated systems minimize manual handling, reduce work-in-progress inventory, and accelerate throughput. For China sheet metal fabrication manufacturers, the development of these flexible cells is a response to demands for smaller batch sizes and faster changeovers without sacrificing efficiency. Visitors can expect to see solutions incorporating robotics for material loading and unloading, alongside software that seamlessly translates design data into machine instructions. This integration represents a shift toward a more streamlined and data-driven workshop floor, a key direction for the future of China metal sheet fabrication.

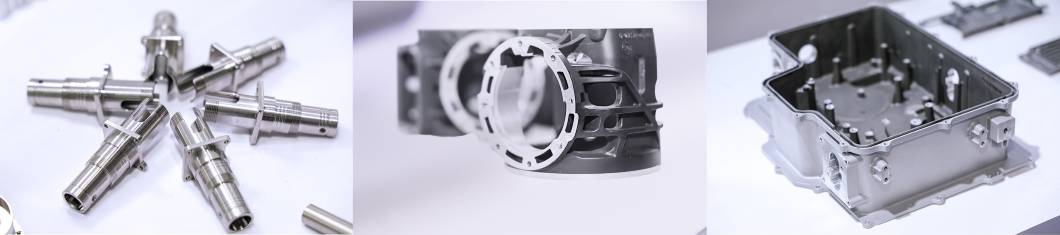

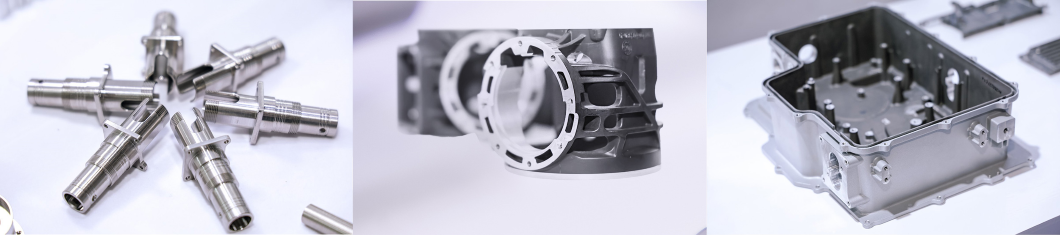

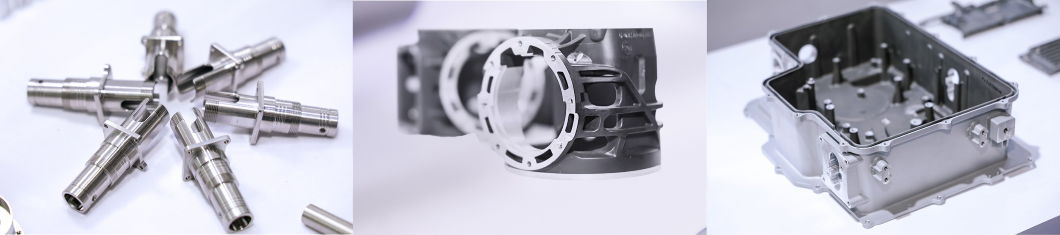

Advances in Precision Forming and Processing Technologies

The core of fabrication lies in the forming and joining processes. The exhibition floor at ITES 2026 will highlight advancements in the precision and capabilities of this equipment. This includes next-generation stamping presses offering higher speeds and precision, alongside laser cutting systems with enhanced power and accuracy for complex contours. For tube and profile processing, exhibits will showcase multi-function machines that perform cutting, notching, and end-forming in a single setup. A specific focus will be on technologies for stainless steel machining and surface treatment, addressing the finishing requirements of industries like medical and high-end appliances. Observing this equipment in action allows for a practical assessment of its potential to improve part quality and reduce secondary operations in your own China metal sheet fabrication workflow.

The Role of Specialized Exhibitors and Manufacturers

The practical value of ITES 2026 is realized through its participants. The event gathers a critical mass of China sheet metal fabrication manufacturers and technology providers. These exhibitors range from global brands to specialized domestic firms that have developed deep expertise in particular processes, such as precision welding or automated bending. Engaging with these companies offers a direct line to understanding current technical capabilities and service models. For procurement and engineering teams, this is an opportunity to discuss specific application challenges with multiple suppliers in a condensed timeframe. The presence of these focused China sheet metal fabrication manufacturers within the larger ITES 2026 ecosystem allows for comparative analysis of different technological approaches to similar production problems, supported by live demonstrations.

The dedicated zone for sheet metal and tube processing at ITES 2026 is configured for professional evaluation. It connects the pressures of cost reduction and efficiency improvement with the tangible equipment and systems designed to meet them. Walking this section provides a consolidated view of how automation, precision machinery, and specialized expertise converge to define modern fabrication. For teams responsible for specifying equipment or optimizing production lines, the event offers a direct assessment of viable paths forward. The range of solutions present supports informed decision-making for capital investment and process innovation. This focused segment of the exhibition underscores how targeted technological adoption can directly influence competitive manufacturing outcomes.