How Automation Upgrades Boost Productivity in Sheet Metal Fabrication Workshops

【Introduction】 How Automation Upgrades Boost Productivity in Sheet Metal Fabrication Workshops

Workshop managers face consistent pressure to deliver higher output without compromising quality or significantly increasing costs. This challenge is particularly acute in the field of China metal sheet fabrication, where manual handling and sequential processes create natural bottlenecks. The integration of automated systems presents a direct method to alter this equation. At ITES China, we monitor how strategic technology adoption transforms operations for China sheet metal fabrication manufacturers, turning constrained workshops into fluid, high-output production environments.

.png)

Addressing Core Productivity Challenges

The path to greater productivity in China metal sheet fabrication involves confronting several interrelated constraints. Traditional workshops often experience significant downtime between processes like cutting, bending, and welding, due to manual part movement and setup. Inconsistency in manual operations can also lead to material waste and rework. Automated solutions address these points directly. Automated material handling systems, robotic welding cells, and CNC-controlled press brakes with automatic tool changers create a continuous flow. This reduces idle time for both machines and operators, increases asset utilization, and ensures repeatable precision. For China sheet metal fabrication manufacturers, this shift is not about replacing labor entirely, but about augmenting human skill with mechanical consistency and endurance, thereby elevating the output and capability of the entire team.

The Integrated Supplier Ecosystem for Automation

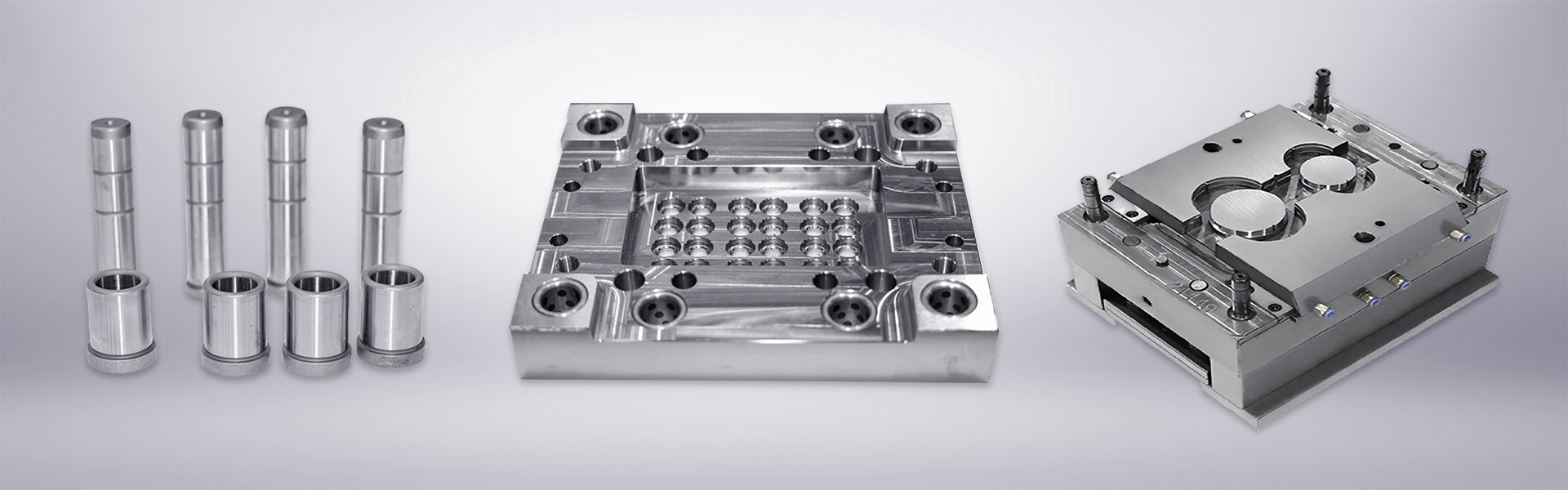

Implementing automation successfully requires more than purchasing isolated machines; it demands compatible systems and reliable support. This is where the concentrated supply chain for China sheet metal fabrication demonstrates a distinct advantage. A network of specialized domestic suppliers provides cohesive solutions, from advanced CNC punch presses and laser cutters to the robotics and software that integrate them. This ecosystem allows China sheet metal fabrication manufacturers to source compatible equipment and technical expertise within a coordinated framework. The benefit is a more streamlined integration process, with reduced risk of interoperability issues between different vendors' machinery. Access to this localized technical support and spare parts network further minimizes potential downtime, ensuring that the productivity gains from automation are sustainable over the long term.

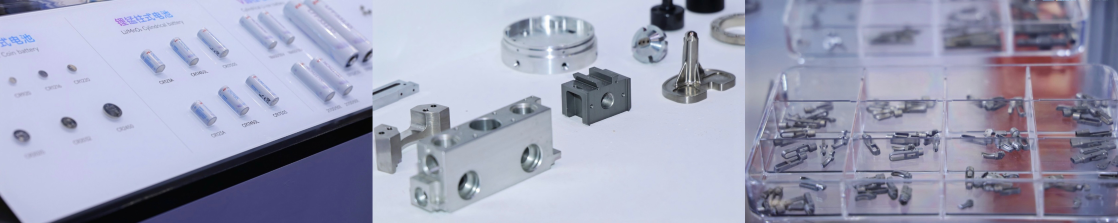

Exploring Solutions at the ITES China Exhibition

To move from concept to implementation, professionals need a venue to evaluate technologies in context. The dedicated zone at ITES China is designed for this critical evaluation. This sector focuses specifically on solving the acute challenges of cost reduction and efficiency improvement across key industries, including new energy, automotive, and medical devices. It presents a focused array of leading process technologies and intelligent solutions for the entire China metal sheet fabrication workflow. Attendees can examine advanced equipment for stamping, welding, tube processing, and surface treatment, often configured in demonstration cells that show automated part transfer. At ITES China, workshop managers and engineers can engage with a wide spectrum of China sheet metal fabrication manufacturers and technology providers. These direct conversations allow for detailed analysis of how specific automated systems—whether a robotic bending cell or an integrated laser cutting and sorting line—can address particular capacity constraints or quality goals in a visitor's own operation.

The transition towards automated production is a strategic response to market demands for speed, consistency, and cost-effectiveness. Observing these integrated systems firsthand provides the clarity needed for investment decisions. The ITES China exhibition assembles the necessary components of this transformation, offering a direct, practical environment to assess the machinery and integrated solutions that redefine workshop productivity. For any business involved in China metal sheet fabrication, engaging with this concentrated display of innovation is a decisive step toward building a more responsive, efficient, and competitive manufacturing operation.