Assembly Automation Solutions in China: Robotics, Screwdriving, Dispensing, and Press-Fit Systems

【Introduction】 Assembly Automation Solutions in China: Robotics, Screwdriving, Dispensing, and Press-Fit Systems

In modern manufacturing, achieving consistent quality and output hinges on precise assembly. For global engineers and procurement teams, China's market for assembly automation solutions presents a wide array of technologies ready for integration. These automated assembly solutions encompass core processes like robotic handling, screwdriving, dispensing, and press-fitting, which form the backbone of efficient production lines. We will examine these key technologies and consider how direct evaluation remains important for successful implementation.

.png)

Core Technologies Defining Automated Assembly

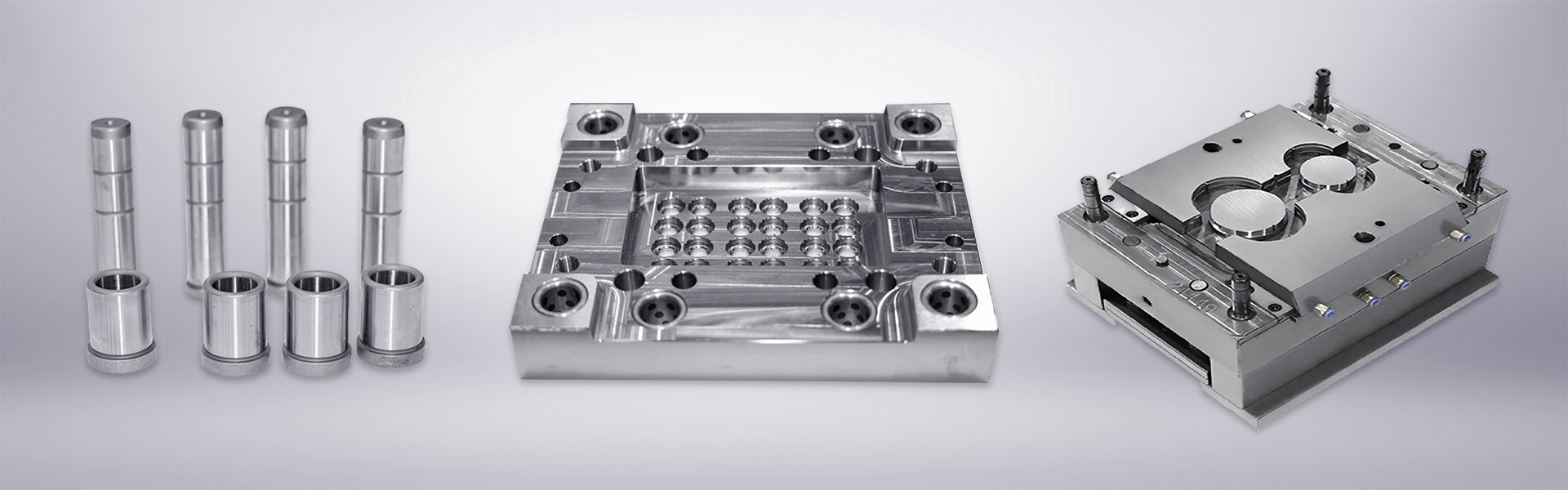

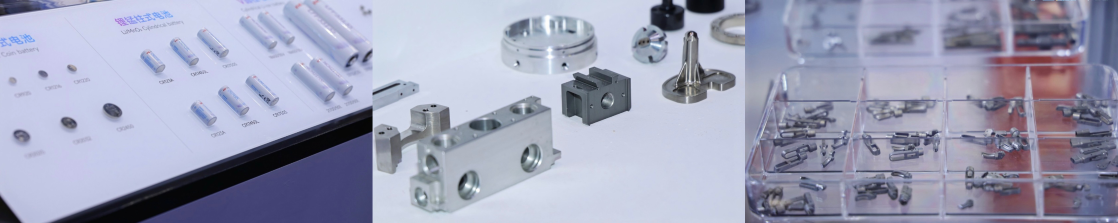

Modern assembly automation solutions are built on specialized systems, each designed for a specific task within the production sequence. Robotic arms provide the flexibility for part placement, transfer, and complex manipulation, serving as the versatile foundation for many automated assembly solutions. Screwdriving units, often fully automated with feeders and torque control, ensure fastening consistency that manual operations cannot match. Precision dispensing systems apply adhesives, sealants, or lubricants with exact path and volume control, critical for product integrity and performance. Finally, press-fit systems deliver controlled force for inserting bearings, pins, or components, eliminating deformation and ensuring reliable interference fits. Together, these systems transform discrete operations into a seamless, synchronized process.

The Supplier Landscape and Integrated System Design

Chinese suppliers in this sector have progressed from offering standalone equipment to providing integrated assembly automation solutions. This shift involves a deeper understanding of the entire production workflow. A capable provider now must consider how a robotic cell interfaces with a vision-guided screwdriver, or how a dispensing unit’s cure time affects the cycle time of a subsequent press-fit station. This systems-level approach is what defines current automated assembly solutions. It requires suppliers to possess strong application engineering skills alongside mechanical and electrical design expertise. For a buyer, the advantage lies in working with partners who can deliver a coordinated system rather than a collection of individual machines, thereby reducing integration risk and streamlining the commissioning phase.

Evaluating Solutions at a Focused Industry Event

For professionals tasked with specifying or procuring these systems, theoretical analysis has limits. Physical demonstration and direct technical dialogue are necessary steps. This is where a platform like ITES Shenzhen provides distinct value. The exhibition features a dedicated segment focused on assembly scenarios for precision components. This area highlights robotic applications, complete equipment lines, and the core technologies that make advanced assembly automation solutions possible.

At ITES Shenzhen, visitors can engage directly with exhibitors showcasing specialized automated assembly solutions. The exhibit range typically includes functioning units for automated screwfastening and tightening, precise soldering and dispensing workstations, and various press-fitting systems. Seeing these technologies in operation, discussing application specifics with engineers, and comparing the approach of different integrators in one location is an efficient method for due diligence. It allows for a practical assessment of system robustness, compatibility with existing facilities, and the supplier’s technical support capabilities. For any team looking to implement or upgrade their assembly process, this direct access to concentrated expertise is a significant opportunity.

The realm of assembly automation solutions in China offers depth and technical maturity, particularly in the core areas of robotics, screwdriving, dispensing, and press-fitting. Moving from component sourcing to implementing integrated automated assembly solutions requires careful partner selection. Industry gatherings like ITES Shenzhen crystallize this vast market into a tangible, accessible format. They enable the hands-on evaluation and detailed conversations that inform sound investment decisions and pave the way for optimized production outcomes. We look forward to supporting these critical evaluations at the event.