Essential Mold Base Components: Frames, Inserts, Slides, and Cores

【Introduction】 Essential Mold Base Components: Frames, Inserts, Slides, and Cores

At the core of every high-volume, high-accuracy plastic or metal part lies a master tool: the precision mold. The functionality and lifespan of this tool are not determined by a single piece of metal, but by the integrated performance of its standardized building blocks. For professionals in manufacturing, a working knowledge of these fundamental elements—the mold base, inserts, cores, and moving components—is indispensable. We at ITES China see this understanding as a foundation for effective communication between designers and makers in precision mold manufacturing. The systematic assembly of these components dictates the mold's capability to produce consistent parts, its maintenance cycle, and its overall cost-effectiveness.

The Foundation: Mold Base Frames and Plates

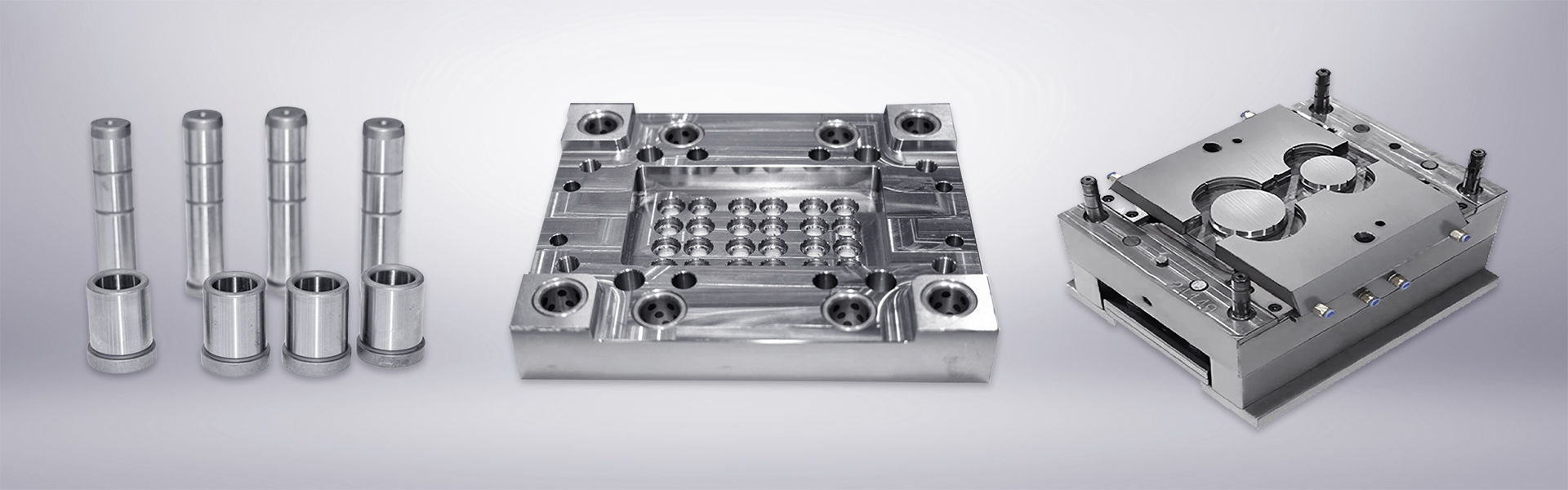

The mold base serves as the foundational chassis, the structural framework that houses all other components. It is typically a standardized assembly of several steel plates. The two primary plates are the cavity plate, which holds the cavity half of the mold form, and the core plate, which holds the core half. Supporting these are the support plates, spacer blocks, and the ejector housing. This assembly must provide immense rigidity to withstand repeated clamping forces—often hundreds of tons—without deflection. Alignment is ensured by precision guide pins and bushings fitted between the plates. Selecting a robust, pre-machined mold base from a reliable precision mold manufacturer is a critical first step, as it establishes the geometric and thermal stability for all subsequent fine detailing.

Forming the Part: Inserts and Cores

While the plates provide structure, the actual part geometry is formed by removable inserts, cavities, and cores. These are blocks of specialized tool steel, often hardened, that are fitted into pockets machined into the base plates. This modular approach is a hallmark of advanced precision mold manufacturing. It allows for the use of different steel grades; a wear-prone core can be made from a tougher, more expensive material than the surrounding plate. Crucially, it simplifies maintenance and modification. A damaged cavity detail can be replaced by machining a new insert rather than reworking the entire monolithic plate. Cores are protrusions that form internal part features, like holes or undercuts, and their precise cooling is often vital for controlling cycle times and preventing part warpage.

Enabling Complexity: Slides, Lifters, and Actions

For parts with geometries that would lock them into a simple two-plate mold, additional moving components are engineered into the system. Slides are assemblies that move perpendicular to the mold's opening direction, driven by angled pins or hydraulic cylinders, to form side holes or external undercuts. Lifters perform a similar function but often move with the ejector plate to free internal undercuts as the part is pushed out. The design and fitting of these components separate a basic mold from a sophisticated one. Their movement must be perfectly synchronized, guided by wear-resistant tracks, and sealed against plastic or molten metal intrusion. The expertise of a precision mold manufacturer is evident in the flawless operation of these mechanisms over hundreds of thousands of cycles.

The Integrated Ecosystem for Mold Development

The efficient production of these complex tools relies on a deeply interconnected supply chain. Access to high-quality pre-hardened and annealed steel stock, standardized mold base components, and specialized vendors for components like heat-resistant cylinders or quick-change couplings is a significant advantage. For projects connected to ITES China, this ecosystem means shorter lead times. A manufacturer can source a standard base, order custom-made inserts from a specialist in EDM machining, and procure certified surface coating services from nearby providers. This collaborative network enables a focus on core competencies—high-speed milling, precision grinding, and assembly—while ensuring every subsystem of the mold meets the required specification from its respective expert.

Precision Molds & Dies at ITES China

The forthcoming exhibition dedicates a comprehensive zone to this very ecosystem. The Precision Molds & Dies segment is structured to serve every professional involved in the tooling lifecycle. It moves from concept to finished tool, showcasing the complete service spectrum offered by exhibitors. This includes upstream activities like component R&D and design, through to the core of precision mold manufacturing and production. Visitors can engage with specialists who demonstrate their capability in processing advanced raw materials, applying critical surface treatment technologies for wear and release, and integrating automation technologies directly into mold design. The scope is explicitly designed to meet the diverse and customized demands of end-user enterprises, providing a direct channel to the upstream experts who build the tools that build your products.

The mold is a system of coordinated components, each with a defined function critical to the whole. Understanding the role of the base, the inserts, and the moving actions provides a framework for specifying and evaluating tooling solutions. This technical comprehension is supported by a supply chain capable of delivering each element to a high standard. Our aim for this exhibition segment is to make that chain tangible and accessible. ITES China presents a consolidated platform where design engineers can consult with mold makers, where procurement can evaluate manufacturing capabilities, and where innovations in materials and surface technology are on display. For any enterprise whose product quality depends on superior tooling, engaging with the specialists in precision mold manufacturing here offers a direct path to achieving those standards.