Selecting Mold Materials: Tool Steels, Aluminum, Copper Alloys, and Hard Alloys

【Introduction】 Selecting Mold Materials: Tool Steels, Aluminum, Copper Alloys, and Hard Alloys

Material science is a cornerstone of successful precision mold manufacturing. The selection of mold base and cavity materials directly governs production cycle longevity, part quality consistency, and overall project economics. For professionals involved in specifying or procuring molds, a functional comparison of common material groups is essential. We at ITES China see this technical choice as a primary factor in mold performance. This article details the properties of key material types, reviews the supplier ecosystem for precision mold manufacturing, and identifies where to evaluate these materials and the expertise required to machine them.

Performance Attributes of Common Mold Material Groups

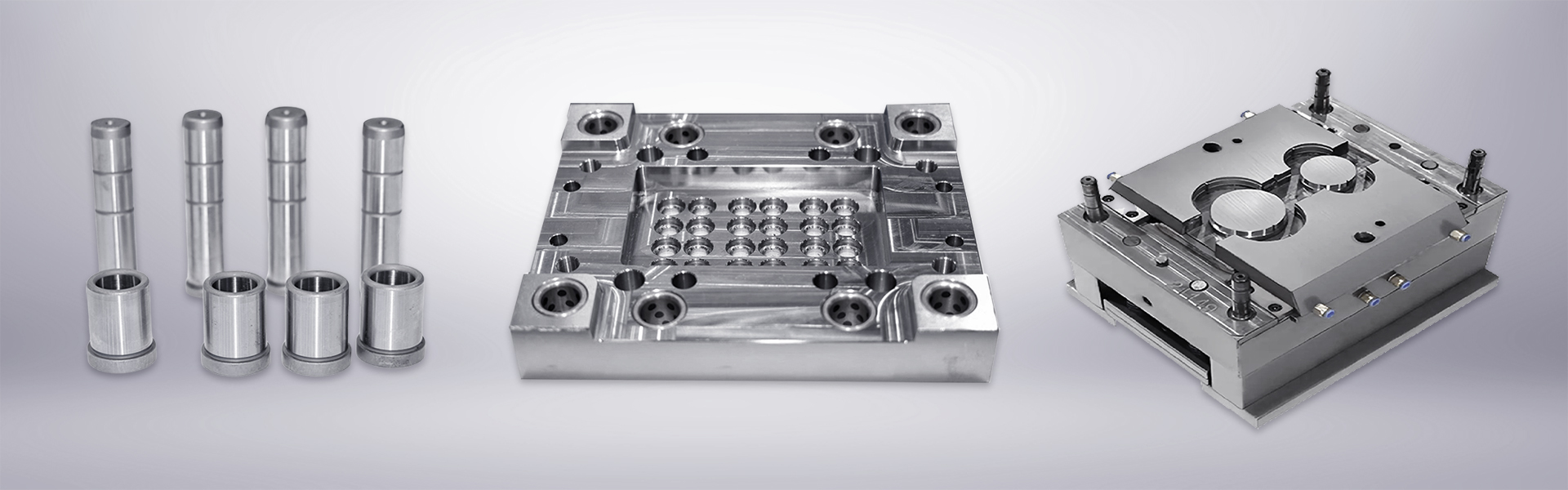

Four principal material categories serve most precision mold manufacturing applications, each selected for specific mechanical and thermal characteristics. Tool steels, such as P20, H13, and S7, are the most widely used for high-volume production molds. They are valued for their hardness, wear resistance, and ability to be heat-treated for enhanced performance. Aluminum alloys offer superior thermal conductivity and faster machining times, making them suitable for prototype molds or lower-volume production where rapid cooling is beneficial. Copper alloys, often used as insert materials, provide exceptional heat dissipation in critical areas of a steel mold. For the most demanding applications involving highly abrasive resins or metal injection molding, hard alloys like tungsten carbide are employed for their extreme wear resistance, despite higher cost and machining complexity.

The Specialized Network for Mold Manufacturing

Executing a precision mold manufacturing project requires more than material procurement; it demands a supplier with integrated capabilities. A capable precision mold manufacturer typically engages from the design phase, advising on material selection for optimal mold life and part ejection. The supply chain supporting these specialists is well-developed, providing access to pre-hardened or annealed steel blocks, premium aluminum plates, and specialized alloy inserts. This network allows a precision mold manufacturer to source certified materials with reliable metallurgical properties, which is fundamental for predicting mold behavior under continuous production cycles. The logistical efficiency of this ecosystem contributes to predictable project timelines.

Engaging with Mold Technology at ITES China

The process of selecting a material and a manufacturing partner is best supported by direct technical engagement. The Precision Component Machining sector at ITES China serves as a central meeting point for this purpose. This zone provides a focused environment where material properties are demonstrated through finished tooling. The exhibition format is designed for practical evaluation. A key feature is the presentation of complete mold manufacturing solutions, where the journey from a raw steel block or aluminum plate to a finished, sampled mold is illustrated.

The composition of exhibitors is particularly relevant. ITES China gathers a concentrated group of enterprises specializing in precision mold manufacturing. This includes dedicated precision mold manufacturer firms that offer end-to-end services from design to trial production. Alongside them are technology providers supplying the advanced machining centers, EDM equipment, and surface treatment technologies essential for working with hard alloys and tool steels. This assembly enables a comprehensive assessment. Visitors—including R&D engineers, procurement specialists, and production managers—can discuss specific material challenges with experts, compare the finishing quality on different steel grades, and evaluate a supplier’s proficiency in managing complex precision mold manufacturing projects that require multiple material types within a single tool.

The longevity and performance of an injection or die-casting mold are inextricably linked to the rationale behind its material selection. Understanding the operational trade-offs between tool steels, aluminum, copper alloys, and hard alloys provides a framework for durable mold design. The concentration of technical expertise found within the precision mold manufacturing sector, supported by a responsive material supply chain, offers a solid foundation for tooling projects. For teams responsible for developing or sourcing production molds, the Precision Component Machining sector at ITES China presents a necessary venue for supplier evaluation and technology insight. We provide this platform to connect material science with manufacturing execution, facilitating partnerships that turn complex designs into reliable, high-performance production tools.