How Modular End Effectors Reduce Downtime in Robot-Driven Assembly

【Introduction】 How Modular End Effectors Reduce Downtime in Robot-Driven Assembly

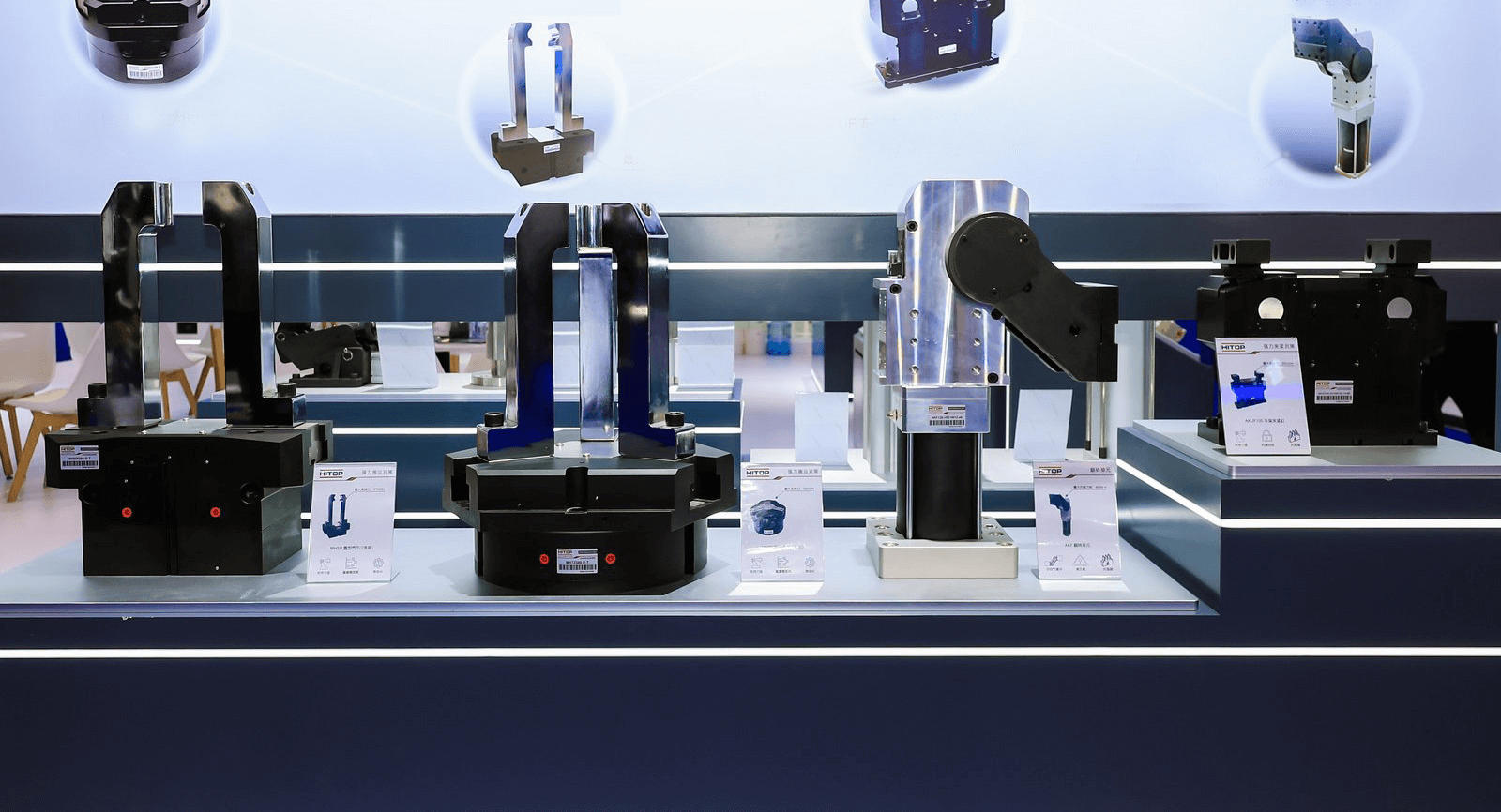

When discussing robot-driven assembly today, one critical factor we consistently consider is how modular end effectors reduce downtime and improve overall operational efficiency. At ITES Shenzhen, we deeply understand that modular robotic tooling isn’t just a technical upgrade — it’s essential for maintaining smooth production lines in high mix, high velocity environments. In practical automation applications, modular designs allow manufacturing systems to adapt quickly to changing product variants and minimize unplanned stoppages, which is a compelling advantage for assembly operations across industries.

Understanding Modularity in End Effector Design

Modularity in the context of end effectors for robots means that a single robotic arm can accept and swap different tooling units without extensive reconfiguration of the entire system. As an end effector manufacturer, we see firsthand that modular end effectors — including quick change grippers, vacuum handling tools, and dexterous multi-fingered hands — significantly reduce the time required to switch tasks on robot arms. Traditional fixed tooling often forces production lines to halt for extended manual tool changes or complex software recalibrations, but modular tooling interfaces can help avoid that. Automated quick change systems, for example, make transitions between gripping, welding, and inspection operations almost seamless, which directly supports shorter cycle times and greater uptime in assembly processes.

Benefits of Modular End Effectors in Assembly

In practical deployment — particularly in electronics, automotive, and precision manufacturing — the value of modular end effectors becomes even more tangible. When a robot needs to perform multiple tasks such as pick and place, screw driving, and part inspection, each task traditionally required dedicated tooling. However, modular tooling systems let robots instantly switch between these tooling types without long pauses. We have observed that this flexibility translates into quantifiable reductions in planned downtime for maintenance and tool changes. Moreover, because modular tooling supports standardized interfaces, robotic systems are more scalable; production engineers can expand or adapt lines without interrupting ongoing operations. This approach aligns with how leading automation strategies are evolving globally to reduce bottlenecks in dynamic manufacturing environments.

Our Perspective and ITES China Supply Chain Advantage

At ITES China, we proudly participate in the ecosystem of precision automation and core component supply chains. China’s manufacturing landscape supports agile configuration and rapid delivery of robot parts, including modular tooling solutions that fit diverse assembly tasks. As an end effector manufacturer serving this vibrant automation community, we work closely with integrators and system designers to ensure that the tooling we provide is compatible with most major industrial robots and collaborative robots. Our presence at this industry platform underscores our commitment to consistent product quality and proactive problem solving — qualities that directly help reduce production downtime and support reliable automation in real world assembly lines. The Chinese supply chain advantage means flexibility in customization and responsive support when clients need to scale or adjust their systems for new production challenges.

Conclusion: Reducing Downtime with Intelligent Modularity

In conclusion, the shift toward modular tooling is not just a trend but a practical necessity in modern automated assembly. At ITES China, we embrace modular end effectors for robots as a core part of our solutions because these systems help factories reduce downtime, adapt to complex tasks, and maintain production continuity. Combining deep supply chain support with modular design flexibility, the solutions we promote enable smoother transitions between operations and greater uptime overall. As manufacturers continue to face dynamic product demands and tighter delivery cycles, modular tooling remains a key strategy for optimizing robot driven assembly performance.